Deliquescent-polyelectrolyte-based full-solid-state ethanol gas sensor enzyme electrode and manufacturing method thereof

A gas sensor and polyelectrolyte technology, which is applied in the direction of instruments, scientific instruments, and electrochemical variables of materials, can solve problems such as unfavorable miniaturization, intelligence and integration, electrolyte evaporation or leakage, and sensor signal attenuation to improve response Selectivity, low cost, and stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of deliquescent polyelectrolyte

[0031] a. In a 100mL three-necked flask, add 0.2mol of diethylenetriamine and 0.2mol of methyl acrylate into 25mL of methanol and react for 12h; React for 1 hour, react for 2 hours at 100°C, react for 3 hours at 120°C, and react for 2 hours under reduced pressure at 140°C. Polyamide;

[0032] b. In a 100mL three-necked flask, mix 5g of hyperbranched polyamide with 50mL of deionized water, 35g of formic acid and 35g of formaldehyde, reflux at 75°C for a certain period of time, then wash with ether for several times, precipitate and dry in vacuum;

[0033] c. Dissolve the product in b above in 50 mL of methanol, then add 10.32 g of n-bromobutane, and react at 50°C for 48 hours. The product is dissolved in methanol, purified by ether precipitation, and vacuum-dried to obtain a deliquescent polyelectrolyte.

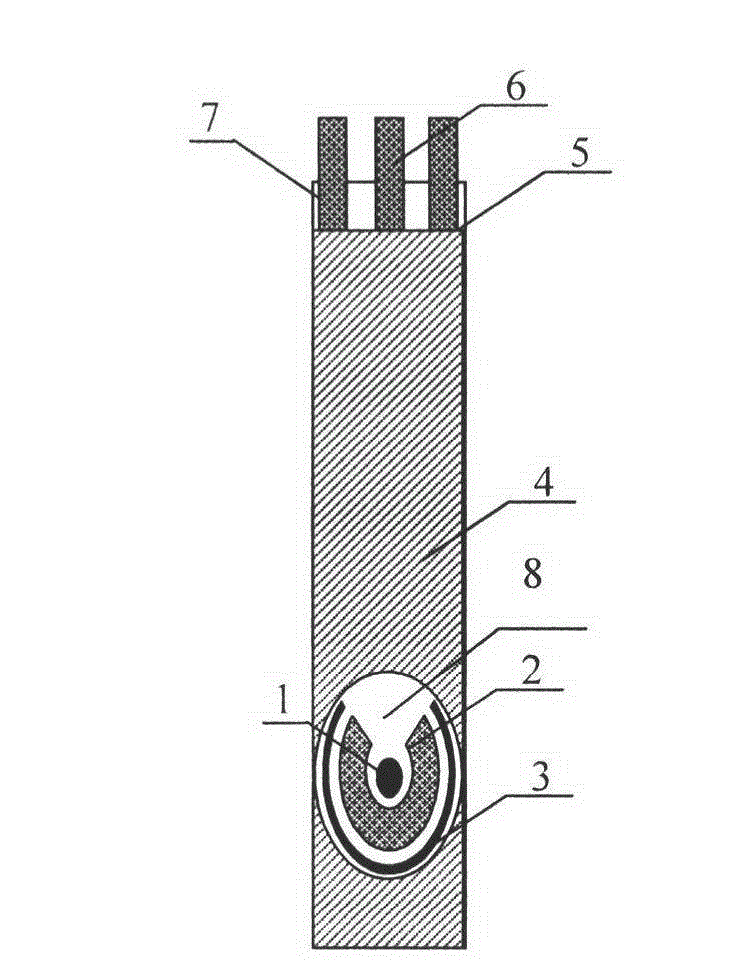

[0034] 2) Clean the ceramic substrate with working electrode (diameter 4mm), silver / silver chloride reference electr...

Embodiment 2

[0038] 1) Preparation of deliquescent polyelectrolyte

[0039] a. In a three-necked flask, add 0.4mol of diethylenetriamine and 0.4mol of methyl acrylate into 50mL of methanol and react for 12h; then raise the temperature to 30°C for 1h under reduced pressure and react at 60°C 1h, react at 100°C for 2h, react at 120°C for 3h, and react at 140°C for 2h under reduced pressure. amides;

[0040] b. In a three-necked flask, mix 10g of hyperbranched polyamide with 100mL of deionized water, 70g of formic acid and 70g of formaldehyde, reflux at 75°C for a certain period of time, then wash and precipitate with ether several times, and dry in vacuo;

[0041] c. Dissolve the product in b above in 100mL of methanol, then add 24.86g of n-bromohexane, react at 50°C for 24h, dissolve the product in methanol, purify it by diethyl ether precipitation for several times, and dry it in vacuum to obtain a deliquescent polyelectrolyte.

[0042] 2) Clean the ceramic substrate with working electrode ...

Embodiment 3

[0046] 1) Preparation of deliquescent polyelectrolyte

[0047] a. In a three-necked flask, add 0.2 mol of diethylenetriamine and 0.2 mol of methyl acrylate to 25 mL of methanol, slowly add 0.2 mol of methyl acrylate dropwise under stirring, and react for 12 hours; then under reduced pressure , heated up to 30°C for 1h, reacted at 60°C for 1h, reacted at 100°C for 2h, reacted at 120°C for 3h, and reacted at 140°C for 2h under reduced pressure. washing in ether, precipitation, and vacuum drying to obtain hyperbranched polyamide;

[0048] b. In a three-necked flask, mix 5g of hyperbranched polyamide with 50mL of deionized water, 35g of formic acid and 35g of formaldehyde, reflux at 75°C for a certain period of time, then wash and precipitate with ether several times, and dry in vacuum;

[0049] c. Dissolve the product in b above in 50 mL of methanol, then add 10.32 g of n-bromobutane, and react at 50°C for 72 hours. The product is dissolved in methanol, purified by ether precipi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com