Complementary type resistive random access memory and production method thereof

A resistive variable memory and complementary technology, applied in static memory, digital memory information, information storage, etc., can solve problems such as complex structure and preparation method, and achieve the effects of reducing device cost, increasing storage density, and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

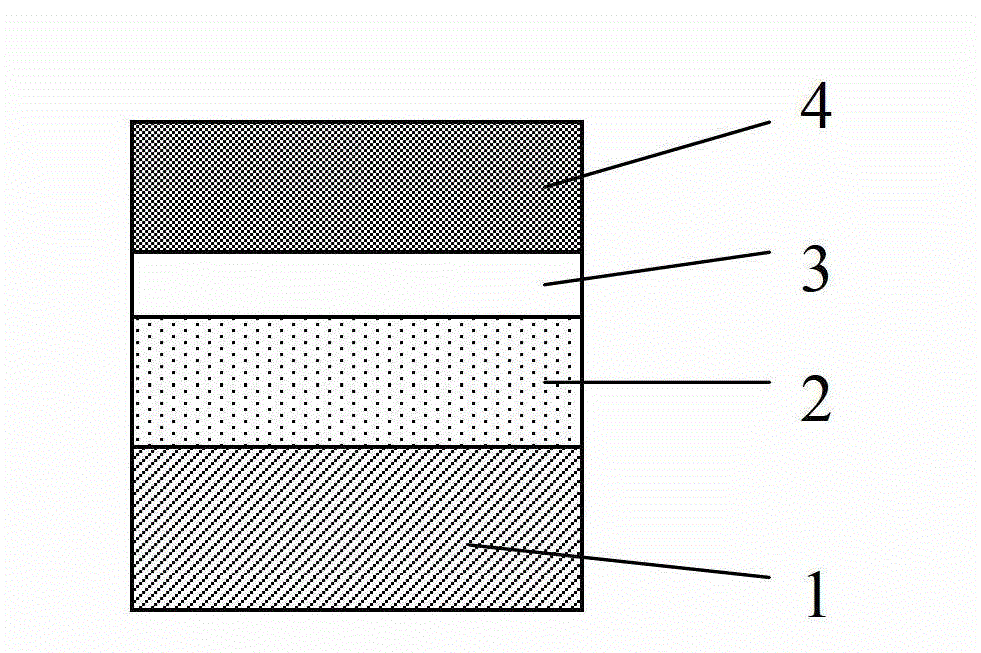

[0037] figure 1 The specific preparation process of the complementary RRAM includes the following specific steps:

[0038] Step 1: Using the method of magnetron sputtering (reaction conditions: the sputtering atmosphere is a mixed gas of 0.25Pa argon and 0.15Pa nitrogen, metal titanium is the target material, the substrate temperature is 300°C, and the sputtering power is 200W) in A titanium nitride film (1) is grown on a thermally oxidized silicon dioxide / silicon substrate with a thickness of 150nm.

[0039] Step 2: Use the method of plasma oxidation (reaction conditions: the reaction atmosphere is 40Pa of oxygen, the plate pressure is 1200V, and the radio frequency power is 300W) to generate an oxide layer on the titanium nitride film in situ, and the surface of the oxide layer is fully oxidized The titanium dioxide storage medium layer (3) has a thickness of 4nm, and under the titanium dioxide layer is a partially oxidized titanium oxynitride storage layer (2) with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com