Preparation method of alpha-type nano aluminum oxide particle

An aluminum oxide and nanotechnology, which is applied in the directions of alumina/aluminum hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of difficult control of conditions, high production cost, complex synthesis process, etc., and achieve easy control of conditions and cost. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

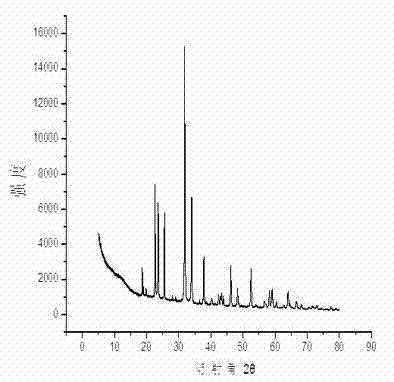

Image

Examples

Embodiment 1

[0019] Step 1. Take 5% aluminum sulfate octadecahydrate and 95% sulfuric acid solution with a concentration of 1.0mol / L according to the mass percentage, use the sulfuric acid solution as a dispersant, add aluminum sulfate octadecahydrate to the dispersant and stir until completely dissolved , prepared aluminum dispersion solution 75mL, set aside.

[0020] Step 2: Add 4.2 g of sodium hydroxide to 75 mL of distilled water, stir until completely dissolved, and prepare a sodium hydroxide solution with a concentration of 1.40 mol / L, heat to 97° C., and set aside.

[0021] Step 3, transfer the aluminum dispersion solution prepared in step 1 to a three-necked flask, and then place the three-necked flask with the aluminum dispersion in a reflux device of a glycerin bath to heat at 95°C; Add the sodium hydroxide solution prepared in step 2 into the aluminum dispersion solution at a stirring speed, a white precipitate is formed, and reflux at a stirring speed of 1000 rpm for 8 hours to...

Embodiment 2

[0024] Step 1. Take 40% aluminum chloride hexahydrate and 60% hydrochloric acid solution with a concentration of 3.0mol / L according to the mass percentage, use the hydrochloric acid solution as a dispersant, add aluminum chloride hexahydrate to the dispersant and stir until completely dissolved , prepared aluminum dispersion solution 75mL, set aside.

[0025] Step 2: Take 1.6 g of sodium hydroxide and add it to 75 mL of distilled water, stir until completely dissolved, and prepare a sodium hydroxide solution with a concentration of 0.533 mol / L, heat to 100 ° C, and set aside.

[0026] Step 3, transfer the aluminum dispersion solution prepared in step 1 to a three-necked flask, then place the three-necked flask with the aluminum dispersion in a reflux device in a glycerin bath and heat to 100°C; at 1500 rpm At a stirring speed of 1500 rpm, the sodium hydroxide solution prepared in step 2 was added to the aluminum dispersion solution, and a white precipitate was formed, which wa...

Embodiment 3

[0029] Step 1. Take 30% aluminum nitrate and 70% nitric acid solution with a concentration of 2.0mol / L according to the mass percentage, use the nitric acid solution as a dispersant, add aluminum nitrate to the dispersant and stir until completely dissolved, and then prepare an aluminum dispersion solution 75mL, spare.

[0030] Step 2: Add 2.4 g of sodium hydroxide to 75 mL of distilled water, stir evenly until completely dissolved, then prepare a sodium hydroxide solution with a concentration of 0.80 mol / L, heat to 98° C., and set aside.

[0031] Step 3, transfer the aluminum dispersion solution prepared in step 1 to a three-necked flask, then place the three-necked flask with the aluminum dispersion in a reflux device in a glycerin bath and heat it to 98°C; at 1200 rpm At a stirring speed of 1200 rpm, the sodium hydroxide solution prepared in step 2 was added to the aluminum dispersion solution, and a white precipitate was formed, which was refluxed for 9 hours at a stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com