Modified phenol formaldehyde resin preparation method

A phenolic resin and modification technology, applied in the field of organic polymer compounds, can solve the problems of reduced polarity, unsatisfactory bonding effect between substrates, poor adhesion, etc., to alleviate molecular steric hindrance, save the addition amount, Increase the effect of high temperature and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

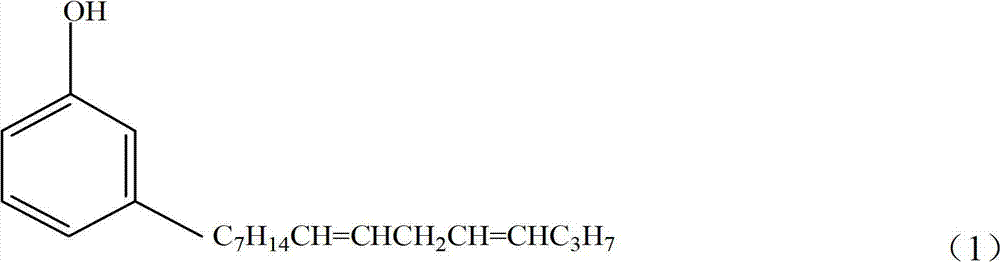

Method used

Image

Examples

Embodiment 1

[0031] Add 10 parts by weight of phenol and 1 part of xylene into the flask, add 1 part of boric acid, adjust the pH to 7.0 with 30wt% sodium hydroxide, heat up to 110 ° C, stir for 2 hours, and then pass the solvent reflux method The water was removed until the reaction was stopped when no more water separated. Here, water is generated while reacting, and the water is continuously removed with reflux, and the reaction ends when no more water is produced. Cool down to room temperature naturally. Add 1 part of cardanol to the above material, 16 parts of 37% formaldehyde aqueous solution (mass content), adjust the pH to weakly alkaline 7.0 with sodium carbonate, raise the temperature to 50°C, and react for 2 hours, then vacuum dehydrate until the obtained product is The viscosity is 2000Mpa.s, and the material is released to obtain the product.

Embodiment 2

[0033] Put 10 parts of phenol and 10 parts of xylene into the flask, add 2.3 parts of boric anhydride, adjust the pH to 8.0 with 60% calcium oxide and raise the temperature to 125°C, react for 5 hours, and then remove the water by solvent reflux until no longer Stop the reaction when water separates out, and let it cool down to room temperature naturally. Then add 12 parts of cardanol and 30 parts of formaldehyde solution with a concentration of 37% to the obtained material, adjust the pH to weakly alkaline 8.0 with sodium carbonate, raise the temperature to 90°C, react for 5 hours, vacuum dehydrate to a viscosity of 3000Mpa.s and discharge.

Embodiment 3

[0035] Put 10 parts of phenol and 5 parts of xylene into the flask, add 0.2 parts of boric acid, adjust the pH to 7.2 with 45% sodium hydroxide, raise the temperature to 120 ° C, react for 3 hours, and then remove the water by solvent reflux until no more Stop the reaction when water separates out, and let it cool down to room temperature naturally. Then add 2 parts of cardanol and 25 parts of formaldehyde solution with a concentration of 37% to the obtained material, adjust the pH to weakly alkaline 7.2 with sodium carbonate, heat up to 70°C, react for 3 hours, vacuum dehydrate to a viscosity of 2400Mpa.s, release Materials, products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com