Arabic gum component grading method as well as product thereby and application of product

A gum arabic and grading method technology, applied in chemical instruments and methods, adhesives, transportation and packaging, etc., can solve problems such as solubility reduction, graded product application value evaluation, destruction of the natural structure and properties of acacia gum, and achieve good stability The effect of enhancing sexuality and bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 thermally modified gum arabic and hyaluronic acid

[0047] The method of the invention is applicable to various modified gum arabic, including thermally modified gum arabic.

[0048] Gum Arabic is a complex polysaccharide containing a small amount of protein components. The polysaccharide part is composed of arabinose, galactose, rhamnose and their uronic acids. The molecular weight is usually about 400,000 Daltons. The polysaccharide moiety joins with the protein components to form a structure known as an "albizia flower" shape, with many polysaccharide units scattered on both sides of the same polypeptide chain. It has been proved by experiments that there are three main components of gum arabic: AGP, AG and GP, which account for about 10%, 90% and 1% of the total amount of gum arabic respectively. Gum Arabic is widely used in industry, usually as binder, stabilizer, emulsifier, spice wrapping material, material to prevent sugar crystallization, stabiliz...

Embodiment 2

[0078] Embodiment 2 standard gum arabic and hyaluronic acid

[0079]The method of the present invention is also applicable to the traditional standard gum arabic without any physical and chemical modification. The standard gum arabic is in the form of coarse particles, and the biopolymer is still hyaluronic acid.

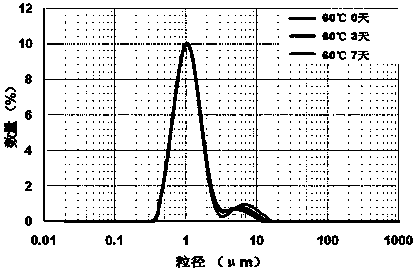

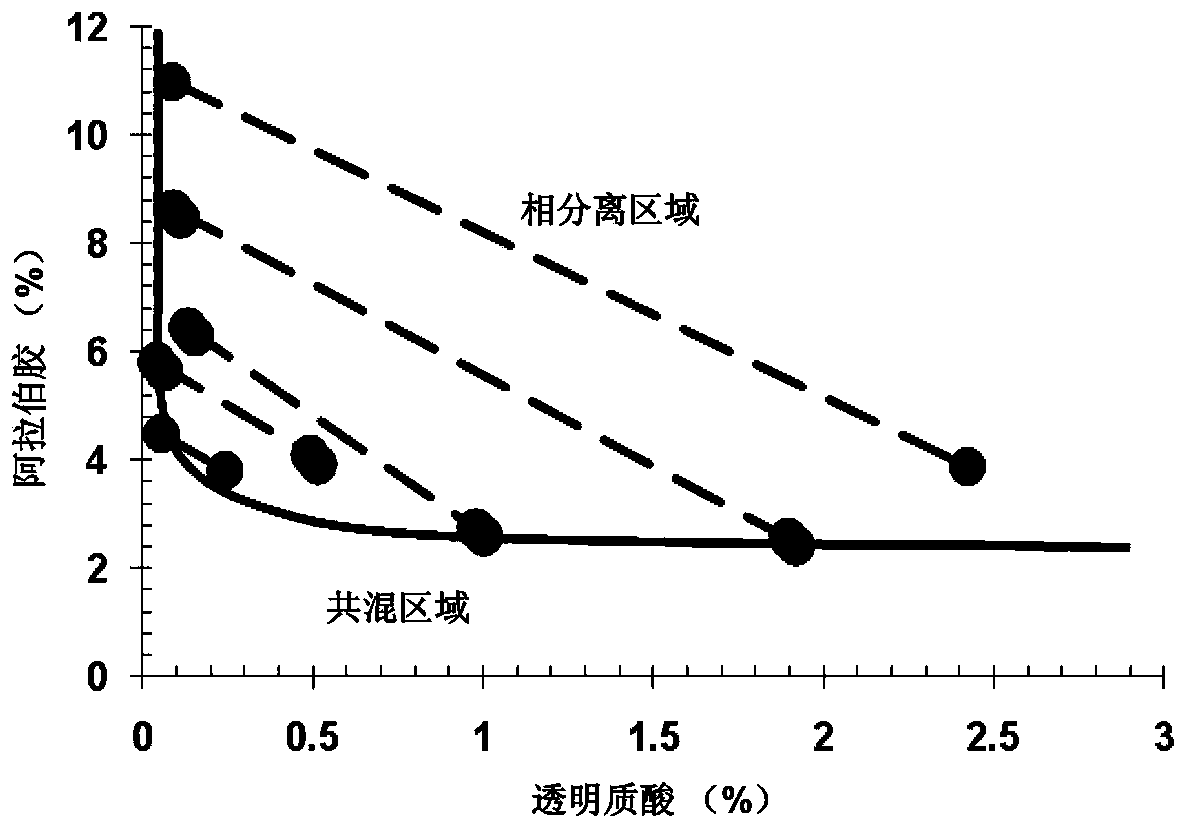

[0080] 1. Induced phase separation

[0081] The weight-average molecular weight of the standard gum arabic sample in the experiment was 560,000 Daltons, and the AGP content was 11%. The weight-average molecular weight of the hyaluronic acid sample is 1.8 million Daltons, and mixing the two sample solutions above the critical concentration will cause phase separation. Compared with thermally modified gum arabic, the molecular weight of standard gum arabic is smaller, so the phase separation critical concentration of standard gum arabic should be different from that of thermally modified gum arabic. The method of observation and GPC-MALLS detection is still used to ...

Embodiment 3

[0091] Example 3 Spray drying gum arabic and beet pectin

[0092] The method of the invention is not only applicable to heat-modified gum arabic and hyaluronic acid system, standard gum arabic and hyaluronic acid system, but also applicable to spray-dried gum arabic powder and negatively charged biopolymer—beet pectin.

[0093] 1. Induced phase separation

[0094] The weight-average molecular weight of the spray-dried gum arabic sample in the experiment was 990,000 Daltons, and the AGP content was 12%. The weight-average molecular weight of the sugar beet pectin sample is 2.6 million Daltons, and mixing the two sample solutions above the critical concentration will cause phase separation. Compared with thermally modified gum arabic and standard gum arabic, the molecular weight of spray-dried gum arabic is between the two, so the phase separation critical concentration of spray-dried gum arabic should be different from the above two. The methods of observation and GPC-MALLS d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com