Equipment and method for continuously preparing high-purity AKD (Alkyl Ketene Dimer) without solvent

A high-purity, solvent-free technology, applied in chemical instruments and methods, ketene preparation, dissolution, etc., can solve problems such as difficult control of reaction temperature, short reaction time, and insufficient purity of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Equipment and method for continuous solvent-free preparation of high-purity AKD

[0056] The raw material is triethylamine in the tertiary amine, and the acid chloride is a mixture of palmitoyl chloride and stearyl chloride, wherein the weight ratio of palmitoyl chloride to stearyl chloride is 7:13.

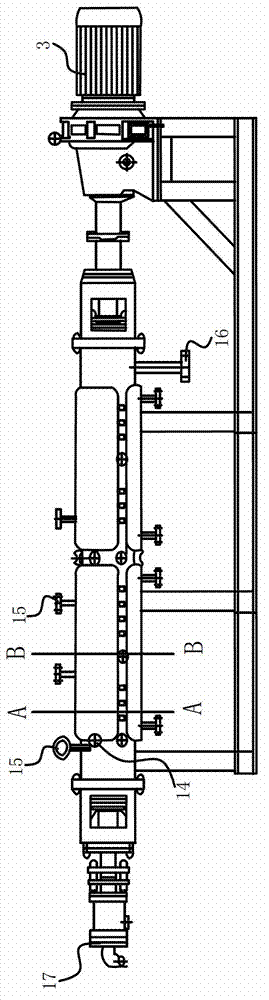

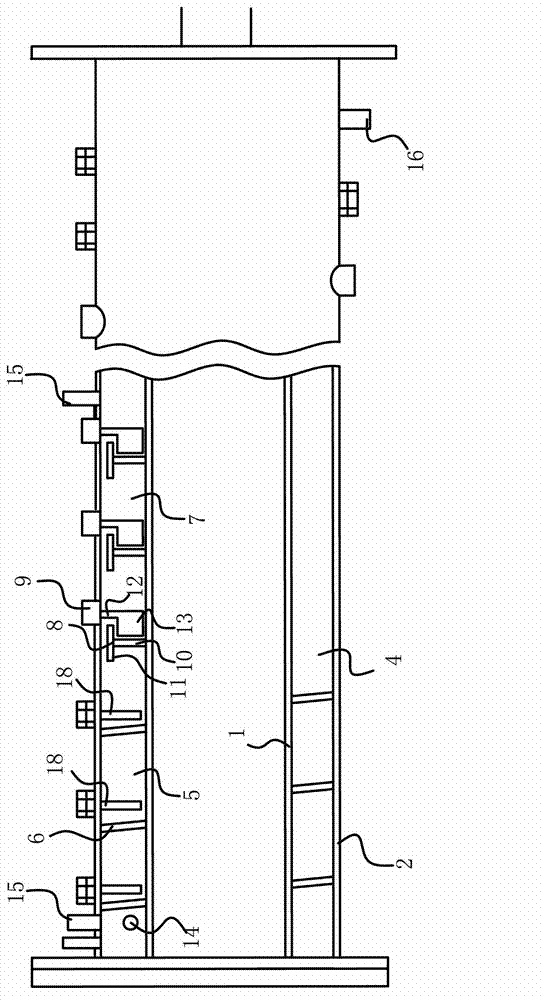

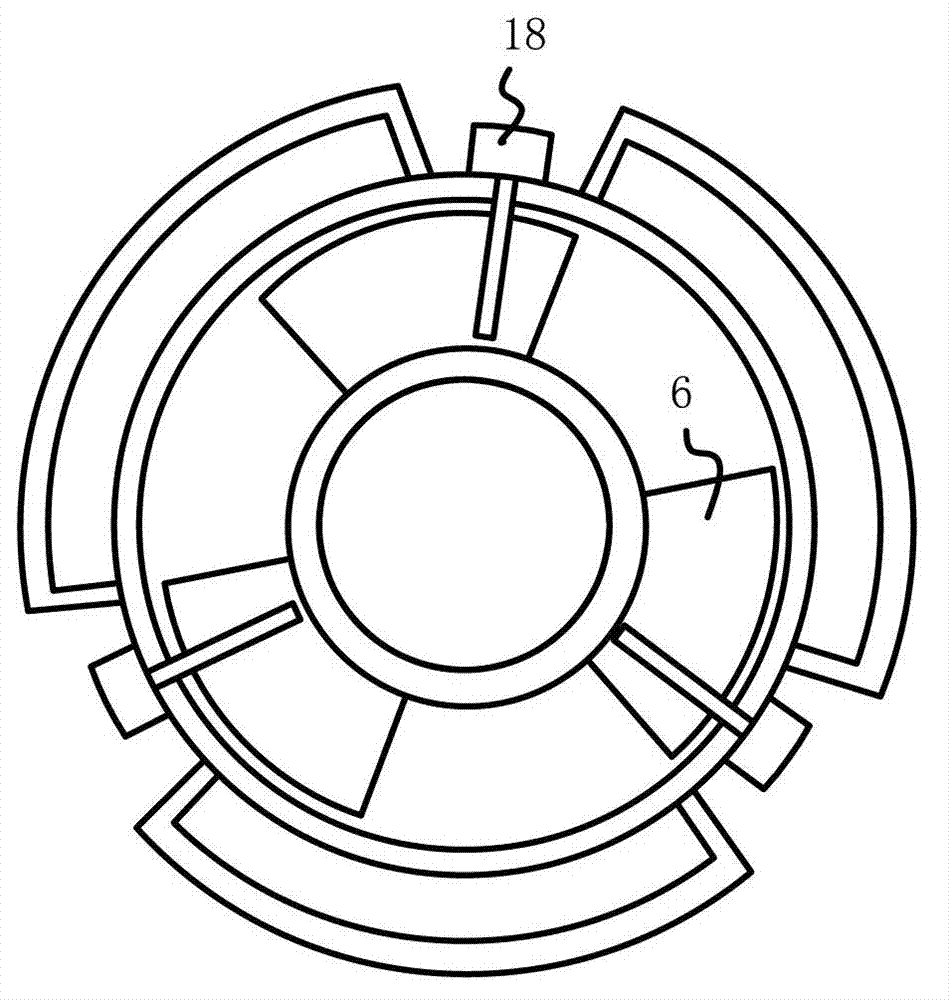

[0057] see Figure 1 to Figure 5 shown, where figure 2 Represented is the internal part shape and distribution schematic diagram in a conveying section 5 and a mixing section 7 in the reactor, image 3 Represents a schematic cross-sectional view of the conveying section 5, Figure 4 Shown is a schematic cross-sectional view of the mixing section 7 . The stainless steel mixing reactor has a length of 1800 mm, an inner cylinder 1 with a diameter of 133 mm, and an outer cylinder 2 with a diameter of 219 mm. The inner cylinder 1 and the outer cylinder 2 are arranged coaxially. In the working state, the inner cylinder 1 is driven by the motor 3 to rotate rela...

Embodiment 2

[0060] Embodiment 2: Equipment and method for continuous solvent-free preparation of high-purity AKD

[0061] see Figure 1 to Figure 5 As shown, the raw material is triethylamine in tertiary amines, and the acid chloride is a mixture of palmitoyl chloride and stearyl chloride, wherein the weight ratio of palmitoyl chloride and stearoyl chloride is 13:7. Equipment, feeding amount, feed ratio are identical with embodiment one. The reactor was operated for 48 hours, and 17 batches were sampled. The iodine value was 44.2~46.2, the average value was 45.25, and the melting point was 48.5~49°C.

Embodiment 3

[0062] Embodiment 3: Equipment and method for continuous solvent-free preparation of high-purity AKD

[0063] see Figure 1 to Figure 5As shown, the stainless steel mixing reactor has a length of 3000 mm, an inner cylinder 1 with a diameter of 370 mm, and an outer cylinder 2 with a diameter of 530 mm. The inner cylinder 1 and the outer cylinder 2 are arranged coaxially. In the working state, the inner cylinder 1 is driven by the motor 3 to rotate relative to the outer cylinder 2. There is a ring cylindrical channel 4 formed between the inner cylinder 1 and the outer cylinder 2. The ring cylindrical channel 4 is divided into five conveying sections 5 along the axial direction. and six mixing sections 7, and the conveying section 5 and the mixing section 7 are arranged one by one in the axial direction of the annular cylindrical channel 4, wherein, the conveying section 5 is provided with blades 6 for conveying and stirring materials, and the conveying section The nominal pitch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com