Method for simultaneously recycling sulfuric acid and organic substances in m-cresol production wastewater

A technology for the production of wastewater and organic matter, applied in the preparation of organic compounds, organic chemistry, natural water treatment, etc., can solve the problem of effective separation and recovery of acid, organic matter, salt, etc., to achieve small footprint, stable operation, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for simultaneous resource recovery of sulfuric acid and organic matter in m-cresol production wastewater, the steps of which are:

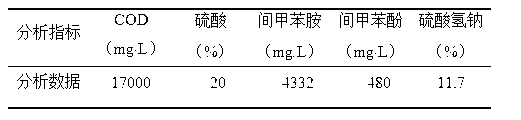

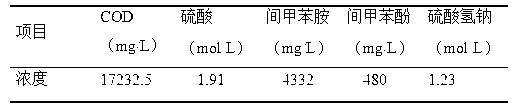

[0037] A) The m-cresol production wastewater was filtered to remove suspended solids; the m-cresol production wastewater to be treated was taken from a chemical plant in Huaian, Jiangsu, and the water quality components are shown in Table 2 below.

[0038] Table 2 Example 1 intermediate cresol production wastewater water quality

[0039]

[0040] B) The m-cresol production wastewater that is filtered to remove suspended matter is pumped into the resin column filled with anion exchange resin with a peristaltic pump at a flow rate of 3BV / h at 20°C; through this step, sulfuric acid and most of the organic matter are adsorbed to On the resin column, sodium salt and a small part of organic matter flow out with the effluent.

[0041] C) After the resin adsorption in the resin column is saturated, stop pumping into the m-cresol prod...

Embodiment 2

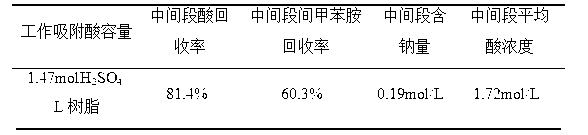

[0049] The waste water quality and basic steps that the present embodiment handles are the same as embodiment 1, and difference is: the flow velocity of pumping into m-cresol production wastewater in step B) and the flow velocity of adding regeneration agent in step D) all increase to 15BV / h, the results show that the increase of the flow rate has no significant effect on the adsorption capacity and regeneration effect, but only reduces the processing time of a batch. The flow rate is increased by four times, and the processing time becomes one-fifth of the original. The separation and regeneration effect of this step is shown in Table 4.

[0050] Table 4 Separation acid regeneration index

[0051]

[0052] Similarly, the flow rate of pumping m-cresol production wastewater in step B) and the flow rate of adding regenerant in step D) are all increased to 30BV / h, which has no significant impact on adsorption capacity and regeneration effect, and the treatment time is short...

Embodiment 3

[0054] The water quality and basic steps of the wastewater treated in this example are the same as in Example 1, the difference is that: the production wastewater in step B) is pumped into the resin column at 5°C, and the volume of each batch is 0.5BV; step C) will effluent The pH of the pH reaches 2 as the critical point of resin adsorption saturation, that is, when the pH of the effluent reaches 2, stop pumping m-cresol wastewater; the volume of the regeneration solution in step D) is 0.25BV, and the dividing line between the front section and the middle section is 0.1BV , the dividing line between the middle segment and the posterior segment is 0.2 BV. The adsorption capacity is reduced, and the acid recovery rate and metal ion recovery rate are both increased. The separation regeneration effect of this step is shown in Table 5.

[0055] Table 5 Separation acid regeneration index (treatment volume 0.5BV)

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com