Bacillus subtilis and application thereof in preparation of gamma-D-polyglutamic acid

A technology of Bacillus subtilis and polyglutamic acid, applied in the field of fermentation engineering, can solve the problems of industrial production of natural γ-PGA, etc., and achieve the effects of cost reduction, convenient and simple operation, and extensive cultivation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Batch fermentation of B. subtilis PG-8 in a 7.5 L tank to produce γ-D-PGA.

[0043] Seed medium: glucose 5g / L, beef extract 5g / L, peptone 5g / L, MgSO 4 ·7H 2 O0.5g / L, use NaOH solution to adjust pH6.8.

[0044] Fermentation medium: glucose 40g / L, monosodium glutamate 40g / L, yeast extract 5g / L, (NH 4 ) 2 SO 4 5g / L, K 2 HPO 4 ·3H 2O2.5g / L, MgSO 4 ·7H 2 O0.1g / L, use NaOH solution to adjust pH6.8.

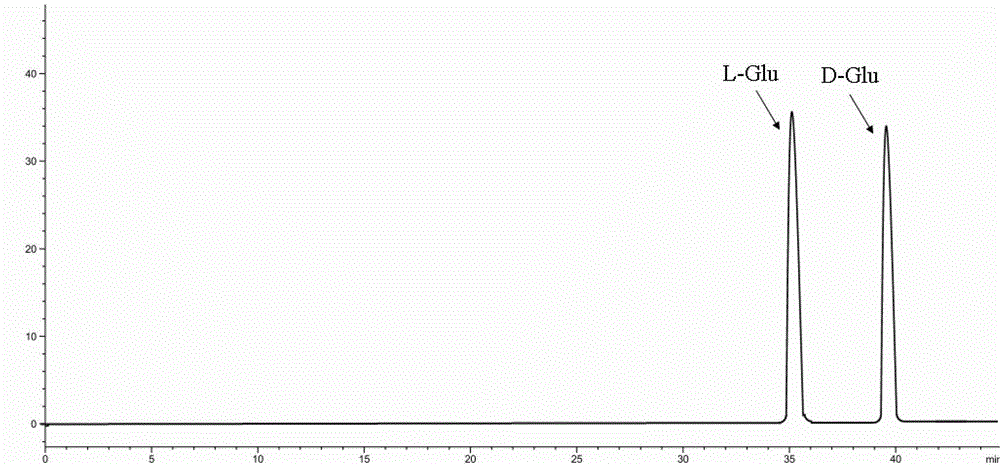

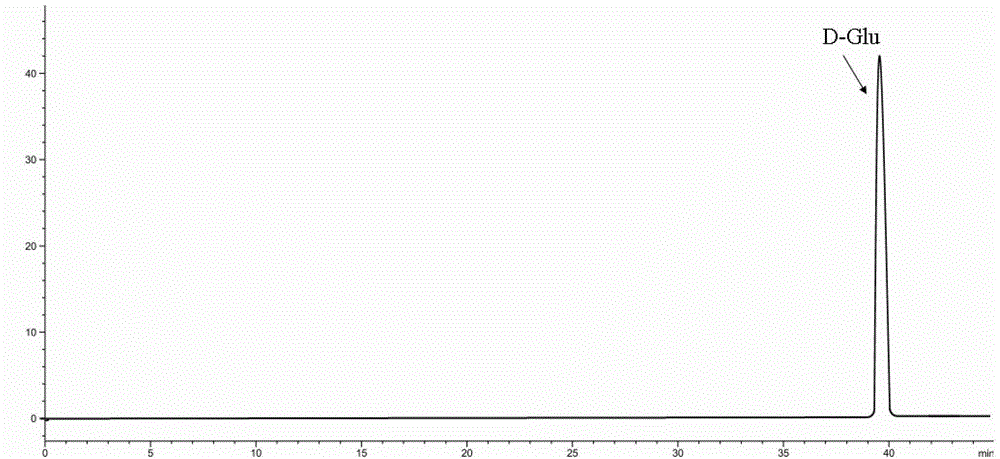

[0045] Cultivate Bacillus subtilis B.subtilis PG-8 (CGMCC NO:6324) in the seed medium, 30°C, 200r / min shaker conditions for 15h, and the seed solution is 5% (v / v) of the seed amount Inoculate in a fermenter pre-installed with 4.5L sterilized fermentation medium for cultivation, culture conditions: 30°C, 400r / min, ventilation rate 1.2L / min, turn on the pH automatic control device during the fermentation process, use HCl Or ammonia water is used to control the pH value of the fermentation broth between 6.5-7.5. After 48 hours of fermentation, the concentratio...

Embodiment 2

[0048] Example 2: γ-D-PGA was produced by fermenting B. subtilis PG-8 in a 7.5 L tank with controlled rotational speed in stages.

[0049] Seed medium: glucose 5g / L, beef extract 5g / L, peptone 5g / L, MgSO 4 ·7H 2 O0.5g / L, use NaOH solution to adjust pH7.0.

[0050] Fermentation medium: acid-treated molasses 20g / L, glucose 10g / L, sucrose 10g / L, peptone 2g / L, (NH 4 ) 2 SO 4 5g / L, MSG wastewater 80g / L, K 2 HPO 4 ·3H 2 O2.5g / L, MgSO 4 ·7H 2 O0.1g / L, use NaOH solution to adjust pH7.0.

[0051] Cultivate Bacillus subtilis B.subtilis PG-8 (CGMCC NO:6324) in the seed medium, 32°C, 220r / min shaker conditions for 16h, and the seed solution is 5% (v / v) of the seed amount Inoculate in a fermenter pre-installed with 4.5L sterilized fermentation medium for culture, culture conditions: keep the temperature at 32°C throughout the fermentation process, the ventilation rate is 1.2L / min, open the pH automatic control device during the fermentation process, Utilize HCl or NaOH to contro...

Embodiment 3

[0054] Example 3: 7.5L tank fed-batch fermentation of B. subtilis PG-8 to produce γ-D-PGA.

[0055] Seed medium: glucose 5g / L, beef extract 5g / L, peptone 5g / L, MgSO 4 ·7H 2 O0.5g / L, use NaOH solution to adjust pH6.8.

[0056] Fermentation medium: molasses 90g / L, peptone 5g / L, (NH 4 ) 2 SO 4 5g / L, MSG wastewater 90g / L, K 2 HPO 4 ·3H 2 O2.5g / L, MgSO 4 ·7H 2 O0.1g / L, use NaOH solution to adjust pH6.8.

[0057] Cultivate Bacillus subtilis B.subtilis PG-8 (CGMCC NO:6324) in the seed medium, 32°C, 200r / min shaker conditions for 16h, and the seed solution is 4% (v / v) of the seed amount Inoculate in a fermenter pre-installed with 4.5L sterilized fermentation medium for cultivation, culture conditions: 32°C, 400r / min, ventilation rate 1.4L / min, turn on the pH automatic control device during the fermentation process, use HCl Or NaOH controls the pH value of the fermentation broth between 6.8-7.2. When the residual total sugar in the fermentation broth is 10g / L, turn on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com