Preparation method for saline solution doped with oxide of anode material of lithium ion battery

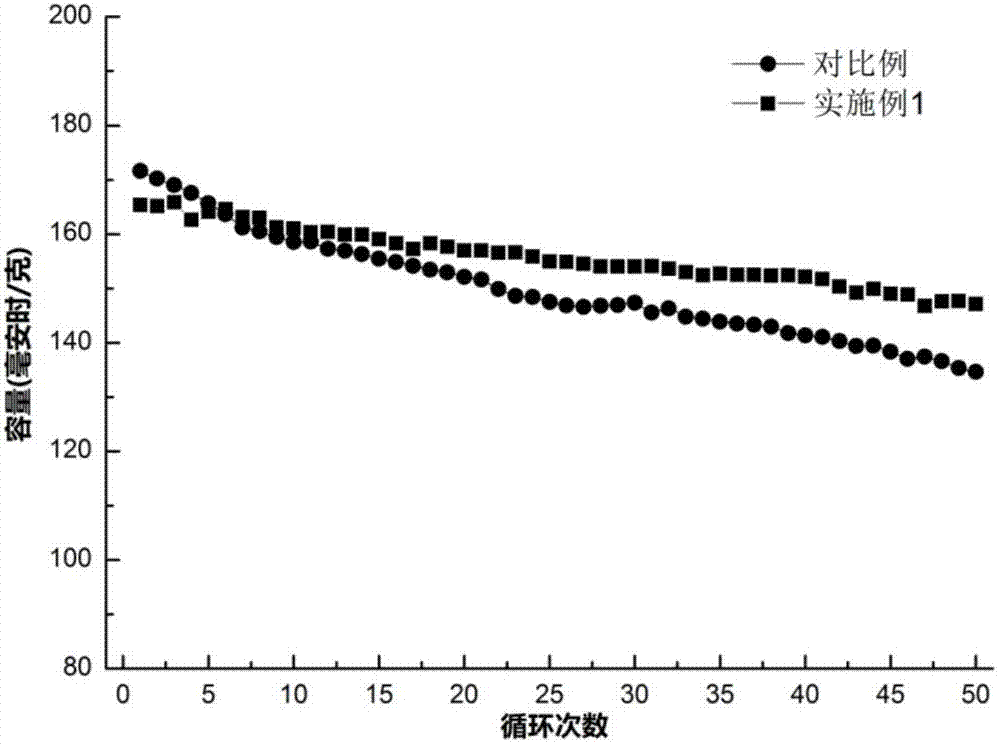

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor high temperature safety performance and cycle performance, slow solid-phase diffusion, and low bulk density of powder materials. Achieve the effect of good cycle characteristics and excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] NiSO 4 、CoSO 4 , MnSO 4 Moore than Ni 2+ :CO 2+ :Mn 2+ =5:2-0.2:3 mixed in a ratio of 5:2-0.2:3, dissolved in deionized water, adding nano-sized aluminum oxide into the solution according to Ni::Co:Mn:Al=5:2-0.2:3:0.2 to form A salt solution with a combined concentration of 2 mol / L. Prepare 4mol / L sodium hydroxide solution, and add NH in the sodium hydroxide solution 3 : Ammonia water with NaOH=0.2. Add the two mixed solutions into the reaction kettle in parallel, and control the reaction in a continuous reaction mode. The pH value is controlled between 10.0-12, and the temperature is 50-60°C. When the particle size meets the requirements, filter, wash, and dry to obtain Ni 0.5 co 0.18 mn 0.3 (OH) 2 ﹒ (Al 2 o 3 ) 0.01 Precursor.

[0025] Weigh lithium carbonate and aluminum-doped precursors according to the molar ratio of Li / (Ni+Co+Mn+Al) = 1.1, mix uniformly for 4 hours, put the uniformly mixed materials into a sintering furnace for sintering, and heat a...

Embodiment 2

[0029] NiCl, CoCl, mole ratio Ni 2+ :CO 2+ :Mn 2+ =7:1.5-0.2:1.5, mix with deionized water, add nano-scale aluminum oxide into the solution according to Ni::Co:Mn:Al=7:1.5-0.2:1.5:0.2 to form a composite A solution with an ion concentration of 2 mol / L. Prepare a 2mol / L sodium hydroxide solution, and add NH to the sodium hydroxide solution 3 : Ammonia water with NaOH=0.2. Add the two mixed solutions into the reaction kettle in parallel, and control the reaction in a continuous reaction mode. The pH value is controlled between 10.0-12, and the temperature is 50-60°C. When the particle size reaches the requirement, filter, wash, and dry to obtain Ni 0.70 co 0.13 mn 0.15 (OH) 2 ﹒ (Al 2 o 3 ) 0.01 Precursor.

[0030] According to the molar ratio of Li / (Ni+Co+Mn+Al) = 1.05, lithium hydroxide and the precursor coated with doped aluminum were weighed, mixed uniformly for 4 hours, and the uniformly mixed materials were put into a sintering furnace for sintering. Raise the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap