Preparation method for flaky nanometer silver powder

A technology of nano-silver powder and flakes, which is applied in the field of preparation of flake nano-silver powders, can solve the problems of cumbersome reaction process, complex reaction operation, and non-single shape, and achieve simple process and equipment, high purity, and single shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0020] The preparation method of the flaky nano-silver powder of the present embodiment is as follows:

[0021] ①Add 0.20g of silver nitrate and 0.04g of PVP-K30 into 15mL of distilled water, stir and dissolve to obtain a silver nitrate solution containing PVP-K30.

[0022] ② Add 0.40 g of ammonium ferrous sulfate hexahydrate into 15 mL of distilled water, stir and dissolve it sufficiently to obtain ammonium ferrous sulfate solution.

[0023] ③ Slowly add the ferrous ammonium sulfate solution obtained in step ② into the silver nitrate solution containing PVP-K30 obtained in step ①, raise the temperature to 60°C, and keep it warm for 30 minutes.

[0024] ④ After the reaction is over, let it stand for 1 hour, then centrifuge the product, wash the solid product three times with absolute ethanol and distilled water, and finally place it in a vacuum drying oven at a temperature of 80°C to obtain the flake nano silver dust.

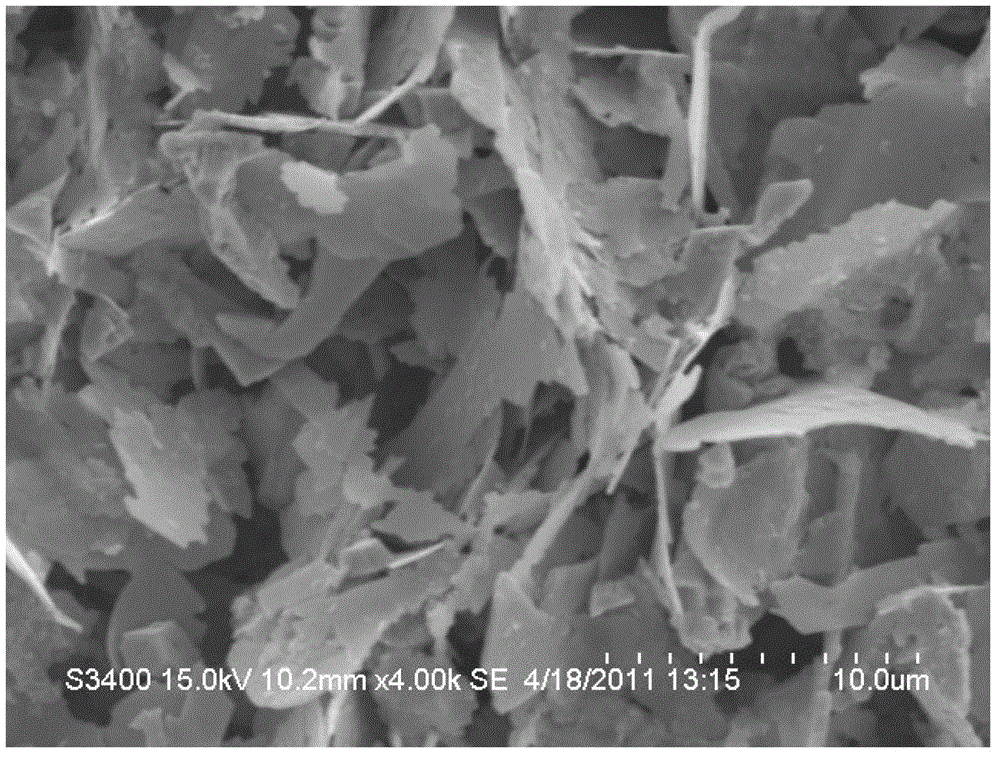

[0025] The SEM figure of the flaky nano-silver powder t...

Embodiment 2~ Embodiment 5)

[0027] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0028] Table 1

[0029] Example 1 Example 2 Example 3 Example 4 Example 5 silver salt Silver nitrate Silver nitrate Silver nitrate silver sulfate Silver acetate Surfactant PVP-K30 PEG-10000 SDS PVP-K30 CTAB Ferrous salt Ammonium Ferrous Sulfate Hexahydrate Ferrous Sulfate Heptahydrate Ammonium Ferrous Sulfate Hexahydrate Ferrous Sulfate Heptahydrate Ammonium Ferrous Sulfate Hexahydrate

Embodiment 6~ Embodiment 9)

[0031] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 2.

[0032] Table 2

[0033] Example 1 Example 6 Example 7 Example 8 Example 9 Example 10 Example 11 Silver nitrate 0.20g 0.20g 0.20g 0.20g 2.00g 2.00g 2.00g PVP-K30 0.04g 0.01g 0.02g 0.40g 0.10g 0.04g 0.40g Ammonium Ferrous Sulfate Hexahydrate 0.40g 0.80g 0.20g 0.10g 2.00g 4.00g 7.00g temperature reflex 60℃ 40℃ 20℃ 50℃ 80℃ 0℃ 60℃ Reaction time 30min 28min 35min 30min 32min 25min 30min

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com