Polyester resin for triglycidyl isocyanurate (TGIC)-cured weather-resistant heat transfer printing powdery paint and preparation method thereof

A technology of polyester resin and powder coating, applied in the field of polyester resin, can solve the problems of insufficient molecular structure, inability to use in batches, heavy adhesion on the surface, etc., and achieve the effect of good effect, clear pattern and texture, and not easy to yellow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

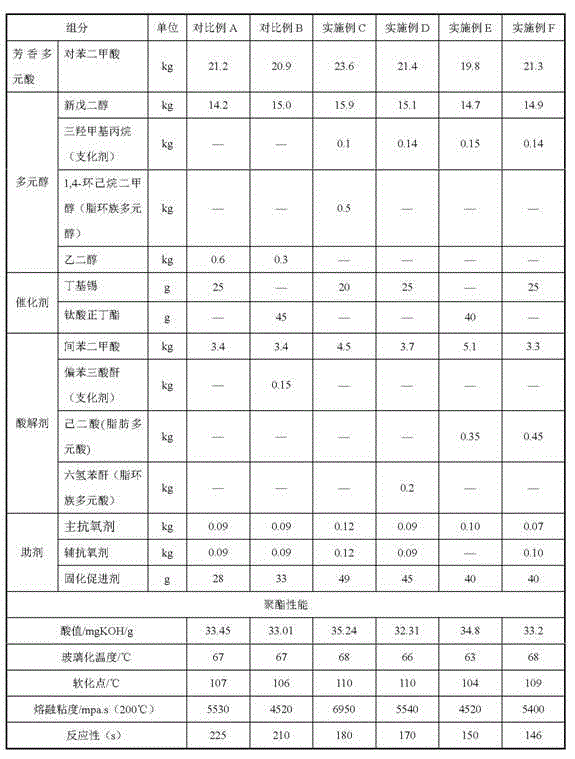

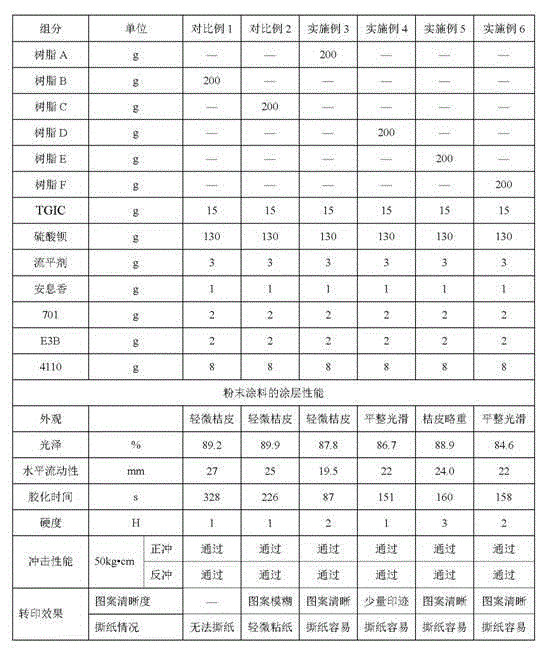

[0025] Some specific examples are listed below to illustrate the present invention. Table 1 is an example of polyester resin, wherein A and B are comparative examples, and C~F are examples of different monomers and process combinations. Among them, formula A and formula B (improved on formula A) is the basic formula for synthesizing ordinary conventional resins. In 50 liters of reactors, add the polyhydric alcohol and the branching agent of the ratio listed in Table 1, heat up to material melting; Then add aromatic polyacid, fatty polyacid and esterification catalyst successively, continue to heat up reaction under nitrogen atmosphere, Rapidly raise the temperature to 180°C, then programmatically raise the temperature to 245°C, record the weight of the esterification water, when the weight of the esterification water reaches 95% of the theoretical water output, take a sample to detect the acid value, the acid value reaches 6-14mgKOH / g, add acid Decompose agent, heat up to 240°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com