Preparation method of Ta (Tantalum) film on bearing steel surface

A technology of bearing steel and film, which is applied in the field of preparation of Ta-based film on the surface of bearing steel, can solve the problems of high-speed and heavy-load bearings, shallow depth, etc., and achieve the effects of improving hardness, reducing surface cracks and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Pretreatment of bearing steel surface:

[0025] GCr15 steel surface polishing and cleaning: The bearing steel used in this embodiment is GCr15 steel. First, the surface of the bearing steel is polished with metallographic sandpaper, and the metallographic sandpaper is sequentially used 200 # 、600 # 、1000 # , 1500 # , 2000 # Sandpaper, and then mechanically polish to Ra≤0.1075μm with diamond abrasive paste as polishing agent, and finally place the polished workpieces in absolute ethanol and anhydrous acetone respectively and use ultrasonic cleaning for 10 minutes, and dry the surface for later use;

[0026] (2) Implantation of basic non-metallic ions

[0027] Put the pretreated bearing steel in a vacuum chamber, the vacuum degree of the back and bottom of the vacuum chamber is ≤2×10 -3 Below Pa, the air leakage rate of the vacuum chamber is ≤0.05Pa L / s; the surface of the workpiece is sputtered and cleaned by ions generated by argon ionization, the sputtering pr...

Embodiment 2

[0033] (1) The three steps of the pretreatment of the bearing steel surface, the implantation of basic non-metallic ions and the deposition of the metal Ta film are the same as in Example 1.

[0034] (2) Implantation of non-metallic ions in Ta-based thin films

[0035] Using high-purity CH 4 The gas was used as the plasma source, and carbon ions were implanted into the Ta film, the implantation voltage was 60kV, the implantation current was 10mA, and the implantation dose was 3×10 17 ions / cm 2 .

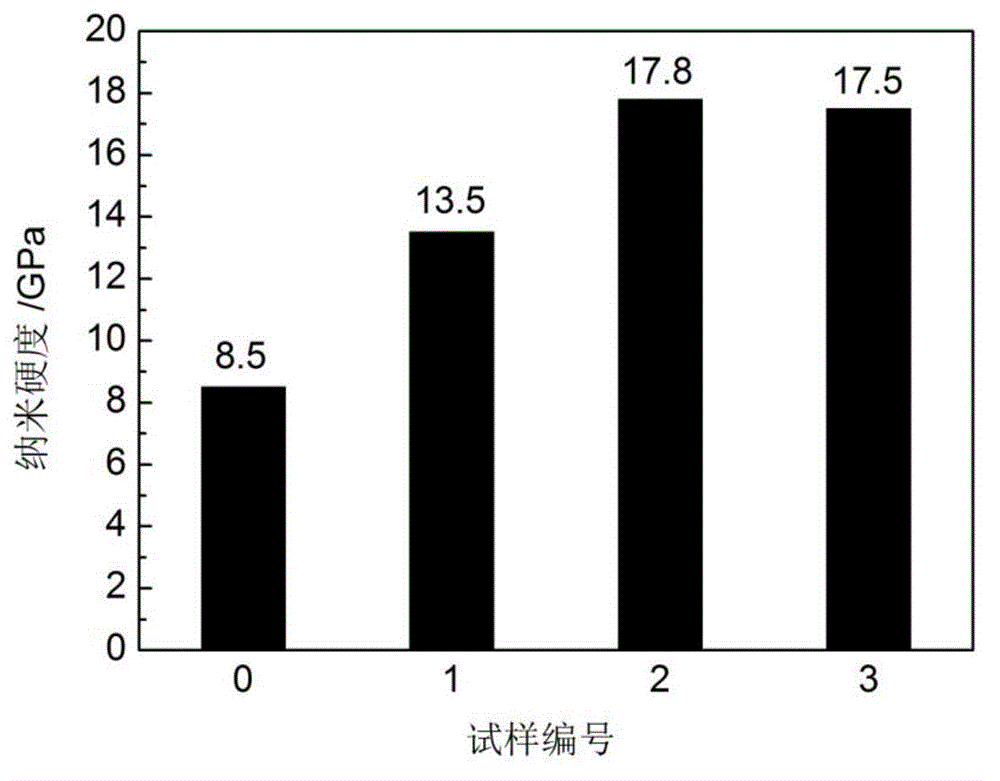

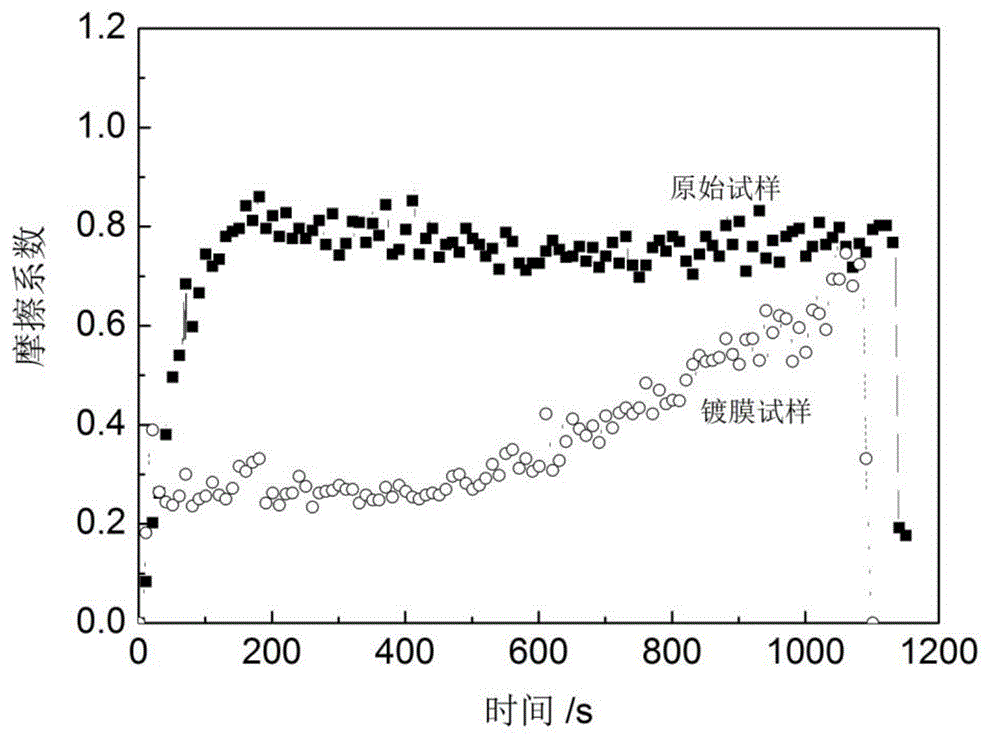

[0036]The prepared bearing steel was tested, and the test results showed that: the surface hardness of the bearing steel increased from 8.5GPa to 16GPa, an increase of 88%; the friction coefficient decreased from 0.8 to 0.2-0.3, specifically as figure 2 As shown; the wear rate has dropped by 65%; there is a certain thickness of diamond-like carbon film on the surface of the film, which greatly improves the hardness and wear resistance of the bearing steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com