Mechanical vibration monitoring special-purposed wireless sensor network node

A wireless sensor and network node technology, applied in network topology, wireless communication, instruments, etc., can solve the problems of slow data access speed, small data storage space, loss, etc., to improve the use time, ensure efficiency and reliability, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

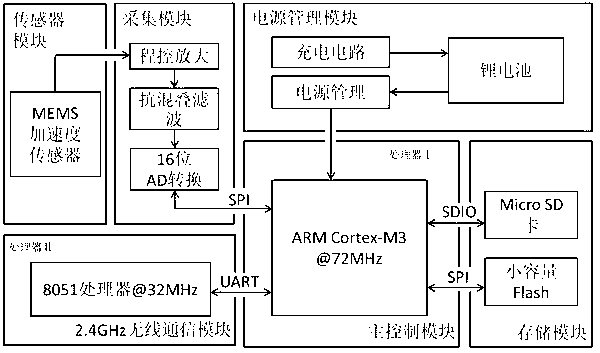

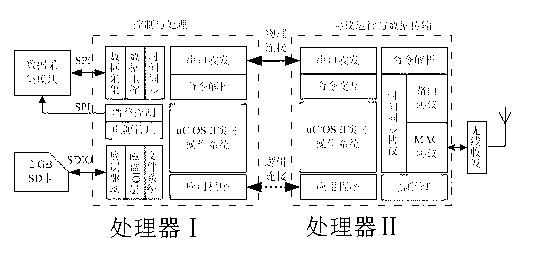

[0028] The structure diagram of the present invention is as figure 1 As shown, the hardware is composed of acceleration sensor, processor Ⅰ, processor Ⅱ, acquisition module, power supply module and storage module. The software part is an embedded real-time operating system. The node adopts a dual-processor architecture. Processor I is responsible for data collection, storage and processing, and processor II is responsible for the operation of wireless communication protocols, and completes tasks such as node ad hoc networking, time synchronization, and data transmission and reception. Processor I and Processor II are connected through board-to-board connectors, and the two control cores perform their duties and cooperate with each other, which enhances the overall performance of the node and reduces the coupling between software and hardware modules, which is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com