Manufacturing method for ferrum-silicon-aluminum magnetic cores

An iron-silicon-aluminum and iron-silicon-aluminum powder technology is applied in the field of preparation of iron-silicon-aluminum magnetic cores, which can solve the problems of high technical difficulty, high equipment and process requirements, and achieve the effects of simple process steps, good superposition performance, and improved product density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

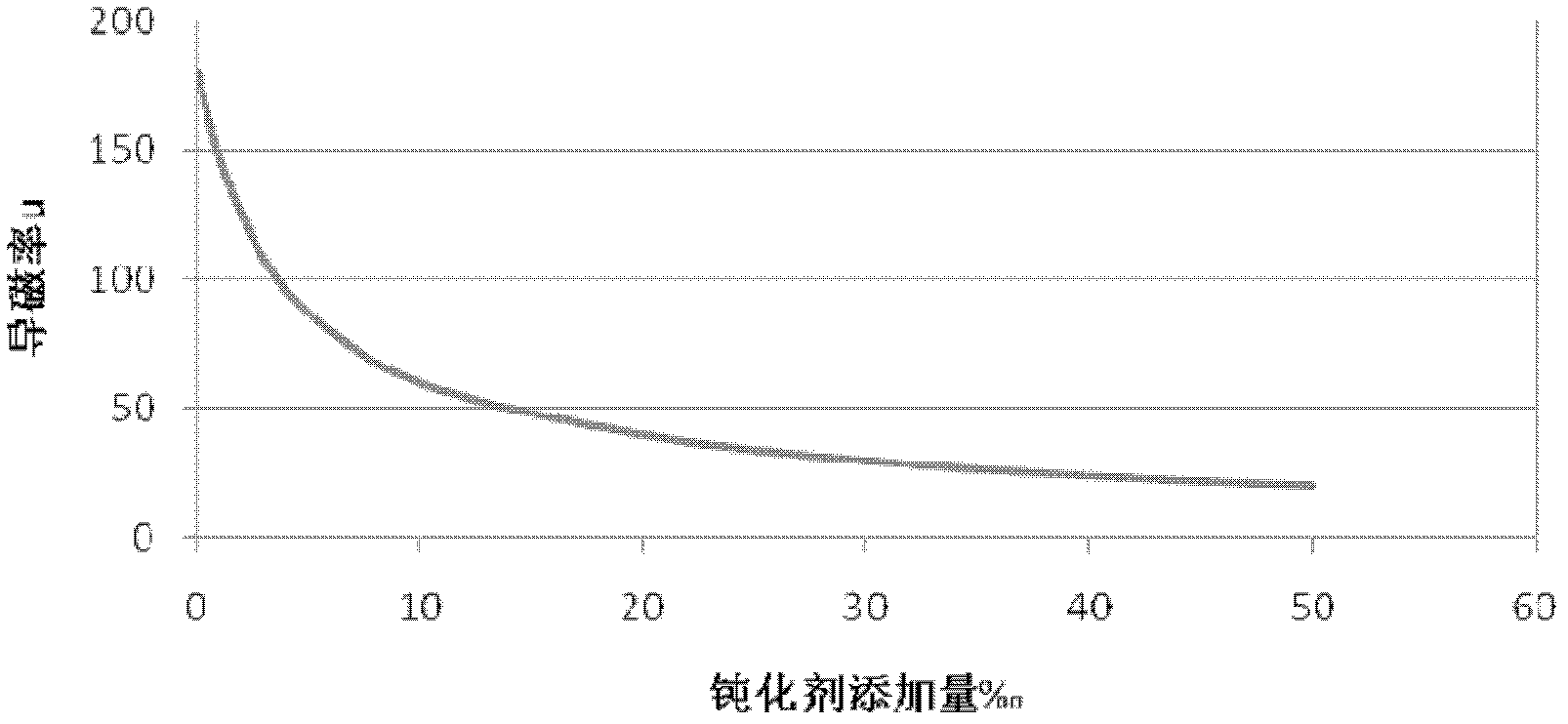

[0032] The change of magnetic permeability of magnetic powder during acid passivation was investigated.

[0033] Get iron-silicon powder, its composition is: Si: 6.5%, Fe: balance, C<300ppm, O<2500ppm; Its particle size ratio is: +180 order powder accounts for 10%,-400 order powder material is 50%, The rest are -180 mesh ~ +400 mesh powder.

[0034] Weigh phosphoric acid according to the weight ratio of iron-silicon powder, dilute it with 25 times the weight of alcohol, add it to the iron-silicon powder, stir evenly, place it for 10 minutes, and spread it out to dry.

[0035] Then add the prepared silicone high-temperature adhesive (siloxane resin with a cracking temperature greater than 600°C) (1.2% + 25‰ alcohol) for stirring, spread out about 1cm in thickness and let it dry; use a 60-mesh sieve before completely drying Sieve through a net to granulate, and then re-dry;

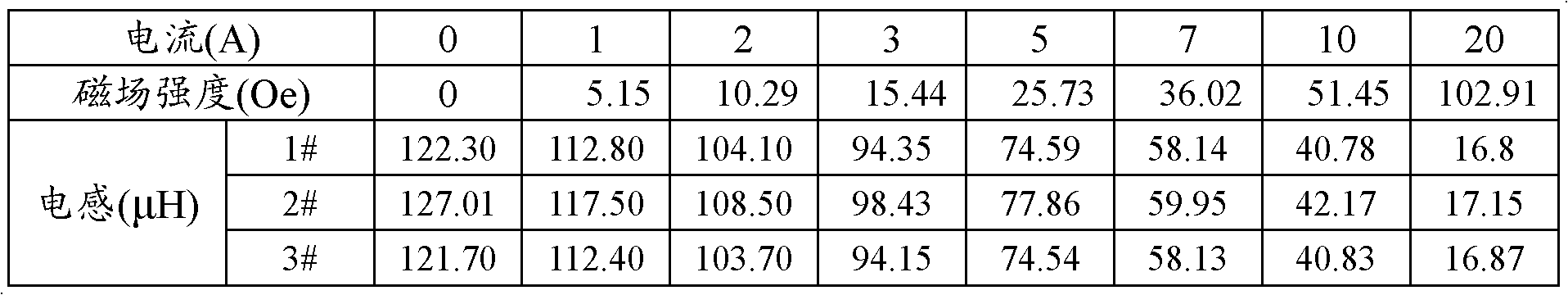

[0036] Add 0.5% zinc stearate and mix well. Dry pressing S270147 product (outer diameter: 26.92mm, in...

Embodiment 2

[0042] Prepare sendust magnetic core according to the method of the present invention, specifically as follows:

[0043] Take sendust powder, its composition is: Al: 5.4%, Si: 9.6%, Fe: the balance; the particle size ratio is: +180 mesh powder accounts for 8%, -400 mesh powder is 45%, and the rest is - 180 mesh ~ +400 mesh powder.

[0044] The following auxiliary materials are weighed according to the weight ratio of sendust powder.

[0045] Weigh 1.5‰ phosphoric acid, dilute it with 30‰ alcohol, add it to the sendust powder, stir evenly, let it stand for 15 minutes, spread it out to dry, and then add the prepared silicone high-temperature binder (the cracking temperature is greater than 600°C Silicone resin) (1.2%+25‰ alcohol) was stirred, spread out to a thickness of about 1cm and aired well; sieved and granulated with a 60-mesh sieve before complete drying, and then dried again;

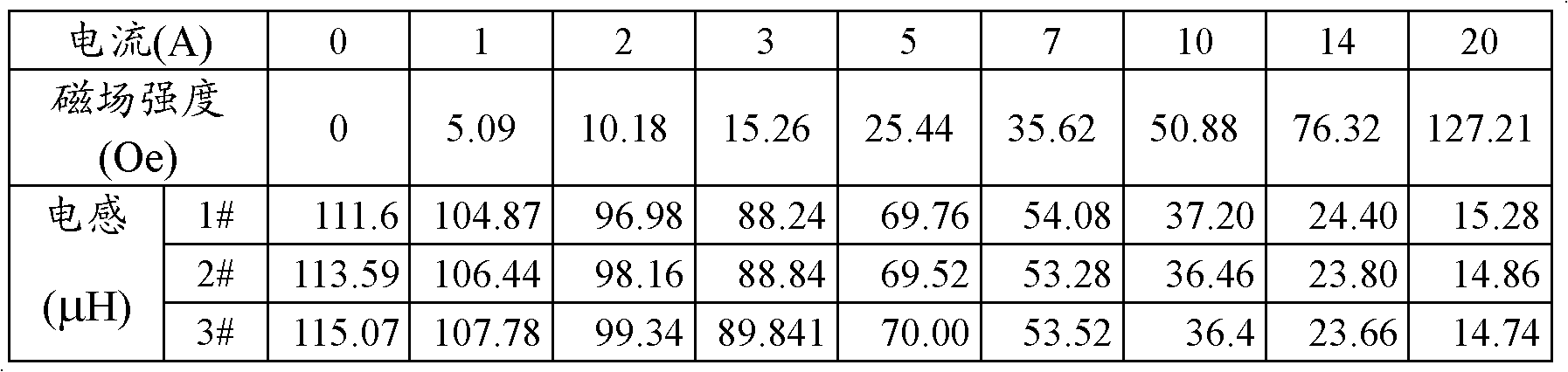

[0046] Add 0.5% zinc stearate and mix well. Dry pressing S270147 product (outer diameter: 2...

Embodiment 3

[0055] Prepare sendust magnetic core according to the method of the present invention, specifically as follows:

[0056] Get sendust powder, its composition is: Al: 5.4%, Si: 9.6%, Fe: balance; Its particle size ratio is: +180 mesh powder accounts for 10%, -400 mesh powder is 50%, the rest is -180 mesh ~ +400 mesh powder.

[0057] The following auxiliary materials are weighed according to the weight ratio of sendust powder.

[0058] Weigh 1.2‰ phosphoric acid, dilute it with 30‰ xylene, add it to the sendust powder, stir evenly, let it stand for 15 minutes, spread it out to dry, and then add the prepared polyamide resin high-temperature binder (1.2%+25 ‰ xylene) was stirred, spread out and aired for 5 minutes, sieved and granulated with a 60-mesh sieve when half-dried, and then re-dried;

[0059] Add 0.5% zinc stearate and mix well. Molded S330147A product (outer diameter: 33.02mm, inner diameter: 19.94mm, height 7.50mm), unit pressure is 18.5T / cm 2 ;

[0060] Then push p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com