Alkali metal flow battery, and preparation method and application thereof

A technology of flow batteries and alkali metals, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low voltage of flow batteries and low energy density of flow batteries, and achieve battery safety protection and easy centralized processing , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

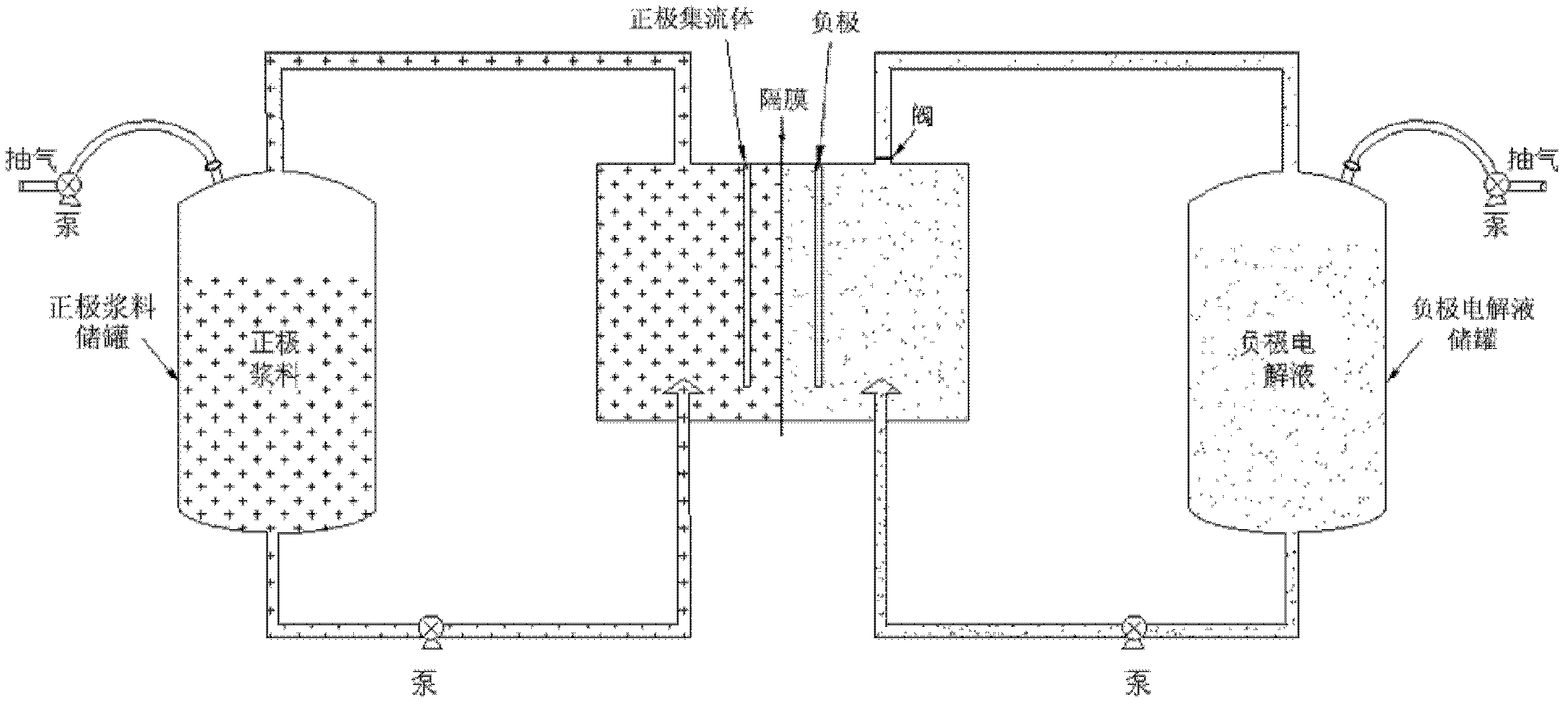

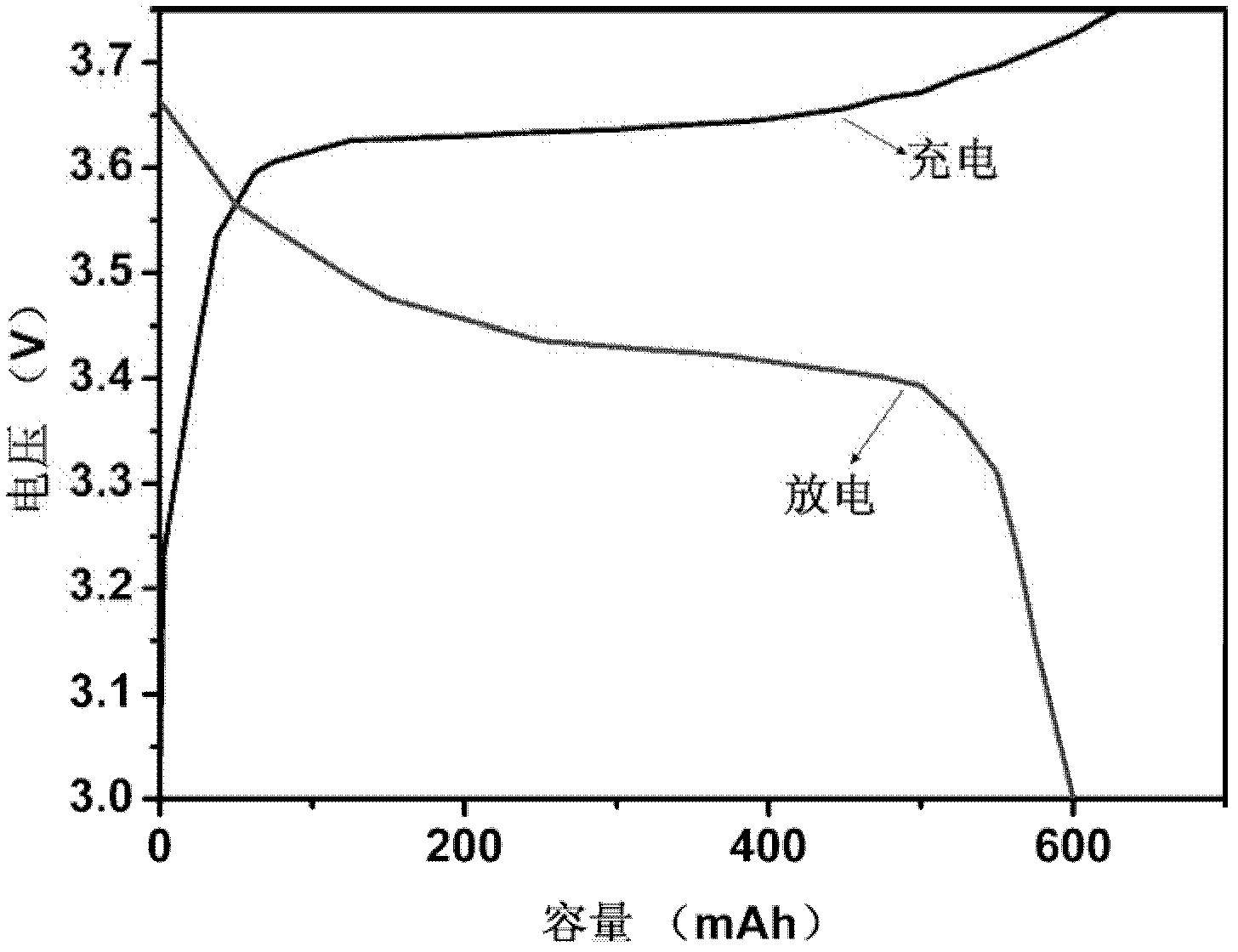

[0039] This example is used to illustrate the alkali metal flow battery of the present invention.

[0040] The positive electrode material is Ni(OH) 2 , the weight percent composition of positive electrode slurry is 28% Ni(OH) 2 , 2% carbon black and 70% electrolyte, the negative electrode material is metal lithium sheet, the positive electrode electrolyte is 1mol / L LiOH aqueous solution, the positive electrode current collector is made of stainless steel, and the negative electrode electrolyte is 1mol / L LiClO 4 PC (propylene carbonate) solution, the diaphragm uses an inorganic ceramic membrane LiCGC (Li 1+x+y Al x Ti 2-x Si y P 3-y o 12 ), charge and discharge at a rate of O.1C, the voltage range is 3.75 ~ 3V, the charge and discharge curve is as follows figure 2 shown.

Embodiment 2

[0042] This example is used to illustrate the alkali metal flow battery of the present invention.

[0043] The positive electrode material is Ni(OH) 2 , the weight percent composition of positive electrode slurry is 30% Ni(OH) 2 , 3% carbon black and 67% electrolyte, the negative electrode material is sodium metal, the positive electrode electrolyte is 2mol / L NaOH aqueous solution, the positive electrode collector is graphite rod, and the negative electrode electrolyte is 1mol / L NaClCl 4 EPC (ethylene propyl carbonate) solution, the diaphragm uses an organic polymer sodium ion conductor membrane, specifically a Nafion composite membrane treated with sodium.

[0044] The specific sodiumization process is:

[0045] a. Treat the film at 85°C in a hydrogen peroxide solution with a concentration of 4V% for 1 hour;

[0046] b. Rinse 4 times with deionized water;

[0047] c. The membrane was exposed to a concentration of 0.5M H 2 SO 4 Treat at 85 degrees for 1 hour;

[0048] d...

Embodiment 3

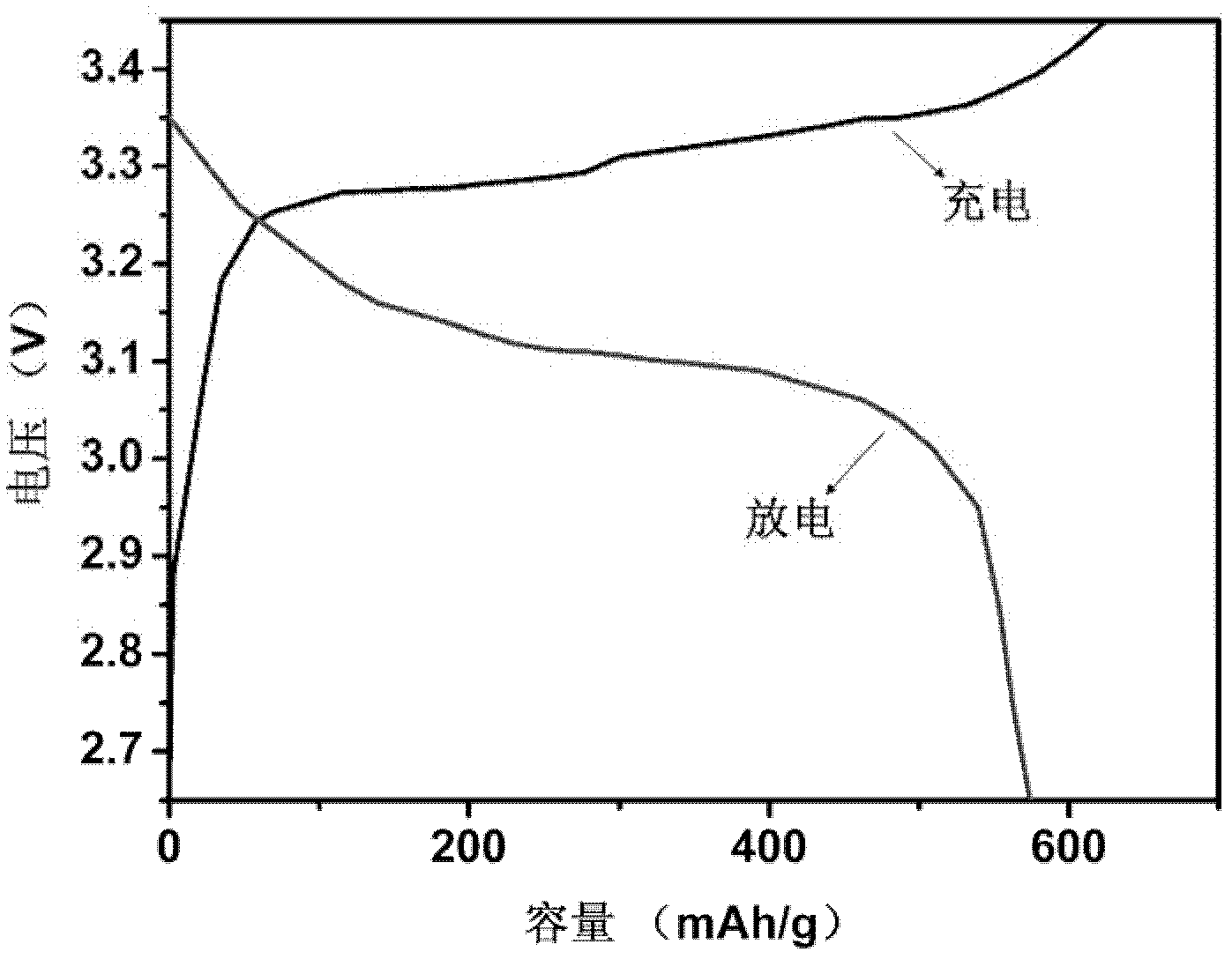

[0053] This example is used to illustrate the alkali metal flow battery of the present invention.

[0054] The cathode material is carbon-coated LiFePO 4 , the weight percent composition of the positive electrode slurry is 24% carbon-coated LiFePO 4 , 1% carbon nanotubes and 75% electrolyte, the negative electrode material is metal lithium sheet, and the positive electrode electrolyte is 2mol / L Li 2 SO 4 Aqueous solution, the positive electrode current collector is made of aluminum sheet, and the negative electrode electrolyte is 1.5mol / L LiBF 4 EC-DMC (1:1) solution (that is, ethylene carbonate-dimethyl carbonate, the volume ratio is 1:1), and the diaphragm adopts the inorganic ceramic membrane LiCGC (Li 1+x+y Al x Ti 2-x Si y P 3-y o 12 ), charge and discharge at a rate of 0.1C, the voltage range is 4.2-2.5V, and the capacity retention rate is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com