Heavy oil hydrogenation protection catalyst, preparation and applications thereof

A heavy oil hydrogenation and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of pollution, reduce metal efficiency, expensive raw materials, etc., and achieve simple and good operation process. Heavy oil protection performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Configure 1mol / L sodium metaaluminate and aluminum sulfate solutions respectively, control the gelation temperature at 35°C, and slowly pass the sodium metaaluminate solution and aluminum sulfate solution into the gelation under the condition that the pH value is guaranteed to be 8-10 In the reactor, and control the gelling temperature at 30-50°C, the whole process automatically adjusts the adding speed of the solution under the condition of ensuring the pH value. The slurry is filtered, the filter cake is washed to neutral, and then filtered with SiO 2 Soak in 20% silica sol solution for 30-60min and stir evenly, then obtain SiO after suction filtration and drying 2 Modified Aluminum Hydroxide.

[0026] Take by weighing 800g of the above-mentioned aluminum hydroxide dry powder and 200g of binder pseudo-boehmite and mix evenly, add 36.92g of 65% nitric acid and 24g of turnip powder, extrude into a clover shape with a circumscribed circle diameter of 1.8mm on the extrud...

Embodiment 2

[0029] Configure 1mol / L sodium metaaluminate and aluminum sulfate solutions respectively, control the gelation temperature at 35°C, and slowly pass the sodium metaaluminate solution and aluminum sulfate solution into the gelation under the condition that the pH value is guaranteed to be 8-10 In the reactor, and control the gelling temperature at 30-50°C, the whole process automatically adjusts the adding speed of the solution under the condition of ensuring the pH value. The slurry is filtered, the filter cake is washed to neutrality, and then dried by suction to obtain SiO 2 Modified Aluminum Hydroxide.

[0030] Weigh 800g of the above-mentioned aluminum hydroxide dry powder and 200g of the binder pseudo-boehmite and mix evenly, add 36.92g of 65% nitric acid and 24g of kale powder, 56.3g of SiO-containing 2 25% silica sol was extruded into a clover shape with a circumscribed circle diameter of 1.8mm on an extruder, dried at 120°C for 6 hours, and calcined at 550°C for 4 hours ...

Embodiment 3

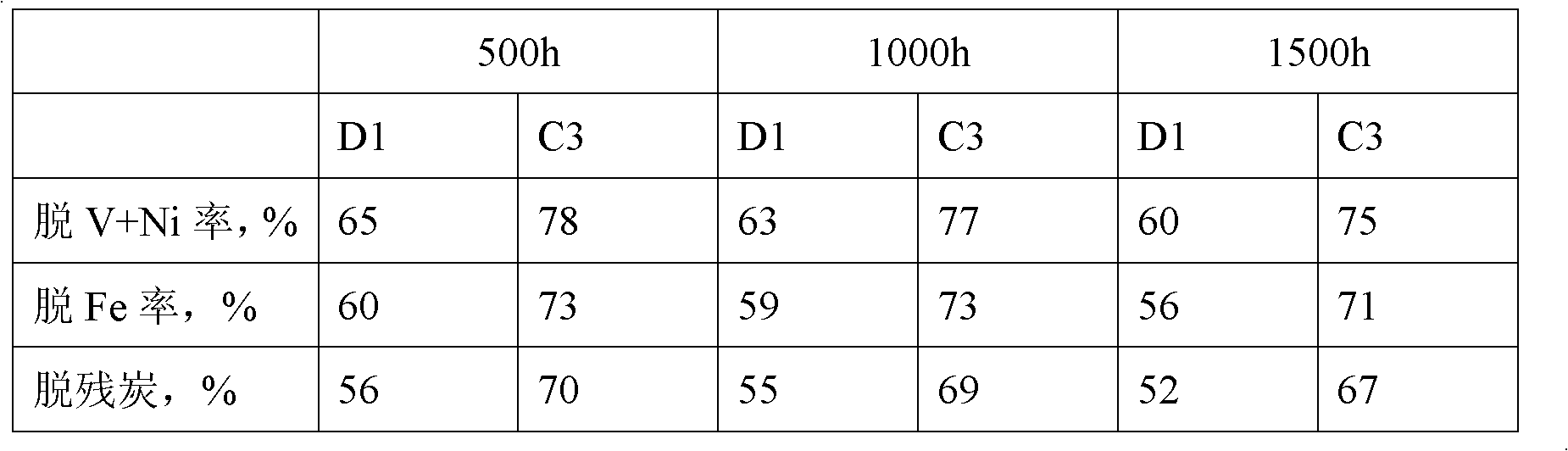

[0033] Using S1 as the carrier, impregnate the mixed solution of nickel hypophosphite, nickel nitrate, and ammonium molybdate on the catalyst carrier, dry it at 120°C, and bake it at 450°C. The catalyst is denoted as C3, and the catalyst contains 5% MoO 3 , 2% Ni 2 P, 1% NiO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com