Technology for processing lead copper matte by ferric chloride

A technology of ferric trichloride and lead matte, which is applied in the direction of improving process efficiency, etc., can solve the problems of high corrosion resistance requirements for equipment materials, increased production costs, and increased environmental burdens, so as to achieve environmental protection and short process , the effect of short leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The chemical composition of lead matte in a factory is as follows:

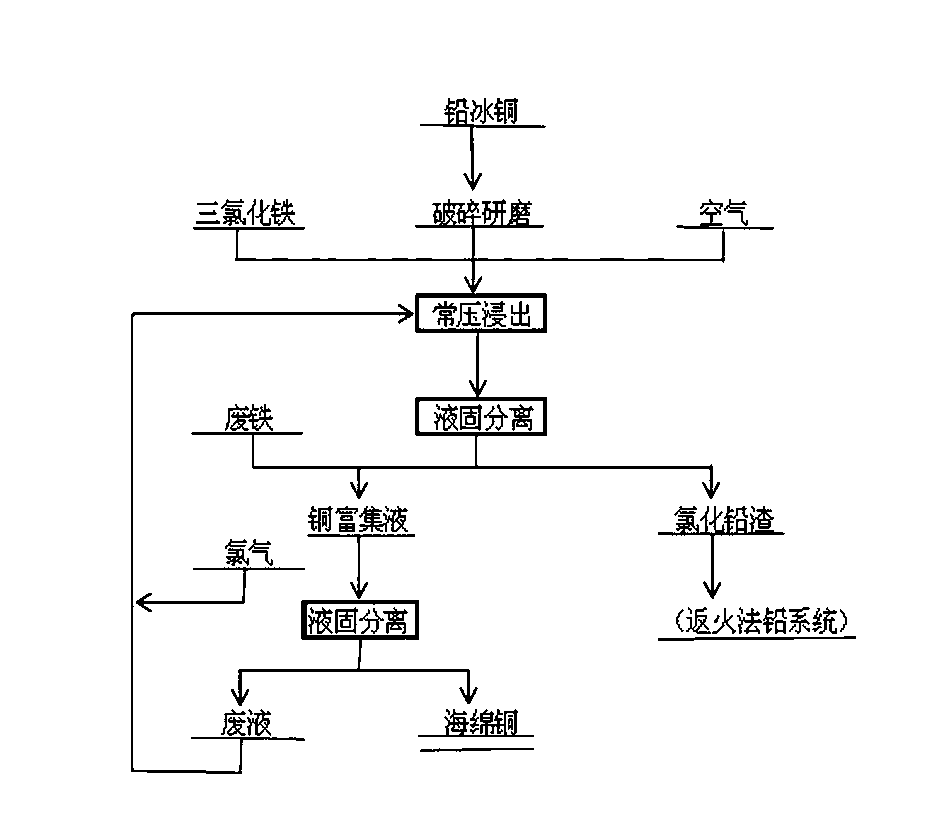

[0046] Pb: 7.83%, Cu: 29.38%, Fe: 36.22%, S: 20.07%, SiO 2 : 3.81%, CaO: 1.14%, Ag: 0.0993%, Zn: 1.11%, Te: 0.11%, Se: 0.21%. Implementation methods such as figure 1 As shown, after grinding the lead matte through an 80-mesh sieve, add the prepared FeCl 3 The leaching solution is fed into the air, the stirring speed is 300r / min, and the leaching is carried out under normal pressure. The leaching conditions are: using FeCl 3 Solution leaching, FeCl 3 The concentration is 300g / L, the liquid-solid ratio is 5:1, the temperature is 89°C, air is continuously fed in, the stirring speed is 300r / min, and the reaction time is 4 hours. The recovery rate of copper is 84.39%.

Embodiment 2

[0048]The chemical composition of lead matte in a factory is as follows:

[0049] Pb: 7.83%, Cu: 29.38%, Fe: 22.60%, S: 19.85%, SiO 2 : 3.02%, CaO: 1.54%, Ag: 0.1022%, Te: 0.19%, Se: 0.31%. Implementation methods such as figure 1 As shown, after grinding the lead matte block material, add the prepared FeCl 3 Leaching liquid, and feed into air, stirring speed is 500r / min, normal pressure leaching, the operation of leaching copper is exactly the same as embodiment 1, and its leaching condition is: adopt FeCl 3 Solution leaching, FeCl 3 The concentration is 350g / L, the liquid-solid ratio is 5:1, the temperature is 95°C, air is continuously introduced, the stirring speed is 350r / min, and the reaction time is 8 hours. The recovery rate of copper is 88.07%.

Embodiment 3

[0051] The chemical composition of lead matte in a factory is as follows:

[0052] Pb: 7.67%, Cu: 29.72%, Fe: 19.53%, S: 20.08%, SiO 2 : 4.52%, CaO: 0.97%, Ag: 0.0633%, Te: 0.17%, Se: 0.26%. Implementation methods such as figure 1 As shown, after grinding the lead matte block material, add the prepared FeCl 3 Leach solution, and feed into air, stirring speed is 300r / min, normal pressure leaching, the operation of leaching copper is exactly the same as embodiment 1, and its leaching condition is: adopt FeCl 3 Solution leaching, FeCl 3 The concentration is 400g / L, the liquid-solid ratio is 5:1, the temperature is 95°C, air is continuously fed in, the stirring speed is 300r / min, and the reaction time is 7.5 hours. The recovery rate of copper is 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com