Method for producing high-conductivity oxygen-free copper and smelting device

A high-conductivity, oxygen-free copper technology, applied in stirring devices, lighting and heating equipment, furnace components, etc., can solve the problems of high production cost, copper volatilization, limited heating and volatilization time, etc., to increase contact The effect of area, low production cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

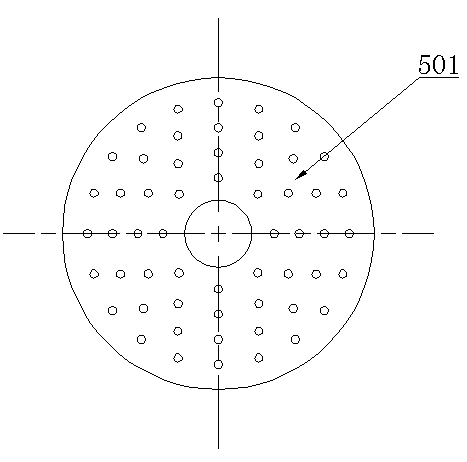

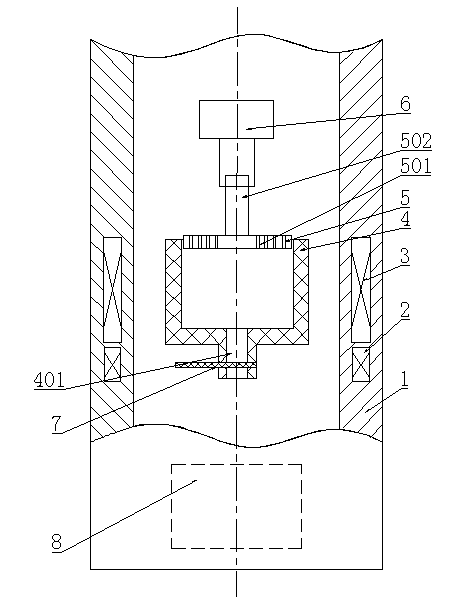

[0033] As shown in the figure, the high-conductivity oxygen-free copper compound device includes a vacuum melting furnace body 1, a main heater 3 is arranged in the vacuum melting furnace body 1, and the cavity of the vacuum melting furnace body 1 A graphite crucible 4 is arranged at the position corresponding to the main heater 3 inside, and a liquid discharge port 401 is provided at the bottom of the graphite crucible 4, and a liquid discharge control valve 7 is provided on the liquid discharge port 401, which is connected with the furnace body of the vacuum melting furnace. The corresponding position of the drain control valve 7 is provided with an auxiliary heater 2; a graphite agitator 5 is suspended in the graphite crucible 4, and the graphite agitator 5 is connected to the central position of the sieve plate 501 by a sieve plate 501 through threads. Composed of lifting rods 502, the sieve holes on the sieve plate 501 in this embodiment are round holes (or square holes). ...

Embodiment 2

[0046] The equipment for preparing high-conductivity oxygen-free copper is the same as that in Example 1.

[0047] During production, the specific steps are as follows:

[0048] 1. Clean raw materials

[0049] Select high-purity electrolytic copper blocks with a purity > 99.95% as raw materials, the iron content of the electrolytic copper blocks is < 2ppm, soak in hydrochloric acid with a mass concentration of 10% at room temperature for 15 minutes, rinse with deionized water, and dry;

[0050] 2. Loading

[0051] Put the dried copper block into the graphite crucible 4, and the material of the graphite crucible 4 is high-purity graphite with ash content<50ppm;

[0052] 3. Melting raw materials

[0053] After the copper block is installed in the graphite crucible 4, start vacuuming. When the vacuum degree reaches 10Pa, start the main heater 3, heat the copper block to 1000°C, and vacuumize the vacuum melting furnace to 0.009Pa, keep it warm for 5h, and fill with protective gas...

Embodiment 3

[0059] In this embodiment, the chemical device for preparing high-conductivity oxygen-free copper is the same as that in Embodiment 1.

[0060] During production, the specific steps are as follows:

[0061] 1. Clean raw materials

[0062] High-purity electrolytic copper blocks with a purity >99.95% are selected as raw materials, and the iron content of the electrolytic copper blocks is <2ppm, soaked in hydrochloric acid with a mass concentration of 10% at room temperature for 15 minutes, rinsed with deionized water, and dried;

[0063] 2. Loading

[0064] Put the dried copper block into the graphite crucible 4, and the material of the graphite crucible 4 is high-purity graphite with ash content<50ppm;

[0065] 3. Melting raw materials

[0066] After the copper block is installed in the graphite crucible 4, start vacuuming. When the vacuum degree reaches 10Pa, start the main heater 3, heat the copper block to 950°C, and vacuumize the vacuum melting furnace to 0.009Pa, keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com