Panax pseudo-ginseng non-woven fabrics and method for preparing same

A technology of Panax notoginseng powder and non-woven fabric, which is applied in spinning solution preparation, non-woven fabric, rayon manufacturing and other directions, can solve the problems of easily causing medical waste, prolonging treatment time, patient pain, etc., and it is convenient to achieve process conditions. Simple control and preparation process, good cell affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

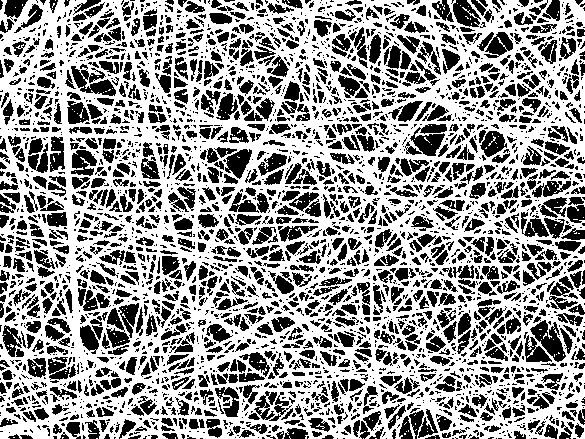

Image

Examples

Embodiment 1

[0019] Take 0.6g of chitosan with a molecular weight of 100,000 and dissolve it in 10g of 80wt.% acetic acid solution at 60°C to obtain a chitosan solution; take 1.0g of polyacrylic acid with a molecular weight of 150,000 and dissolve it in 10g of deionized water to obtain Polyvinyl acid solution; after mixing according to the mass ratio of chitosan solution: polyacrylic acid solution = 1:1, add 0.16 g of Panax notoginseng powder of 1500 mesh (about 170 nm in diameter), and perform ultrasonic mixing for 0.5 h to obtain spinning Silk solution; after injecting the above spinning solution into a syringe (capacity of 20mL) with a flat needle (1.2mm inner diameter), fix the syringe on the micro-injection pump, place a metal receiving screen at a distance of 15cm from the needle, and place the needle and 20 kV high-voltage DC power supply was connected, and the flow rate was set at 1.0 mL / h for electrospinning. After 20 h, the fiber membrane on the receiving screen was collected. The...

Embodiment 2

[0022] Take 0.3g of chitosan with a molecular weight of 200,000 and dissolve it in 10g of 80wt.% acetic acid solution at 60°C, take 0.3g of polyacrylic acid with a molecular weight of 400,000 and dissolve it in 10g of deionized water, and then dissolve it according to the chitosan: polyethylene After mixing at a mass ratio of acid=9:1, add 0.06 g of Panax notoginseng powder of 1500 mesh (about 170 nm in diameter), and perform ultrasonic mixing for 0.5 h to obtain a spinning solution; After injecting the above spinning solution into the mL syringe, fix the syringe on the micro-injection pump, place a metal receiving screen at a distance of 15 cm from the needle, connect the needle to a 20 kV high-voltage DC power supply, and set the flow rate to 1.0 mL / h for electrospinning After 20 h, collect the fibrous membrane on the receiving screen, which is a superfine fiber membrane with a diameter of about 100-300 nm.

[0023] The fibrous membrane can be made into wound materials or dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com