Preparation method of catalyst

A catalyst, zinc chloride technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of lower methanol conversion rate of raw materials, insufficient utilization rate of raw materials, inability to achieve methanol conversion rate and methyl alcohol conversion rate. mercaptan yield and other issues, to achieve the effects of reducing production costs, reducing reaction temperature and pressure, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

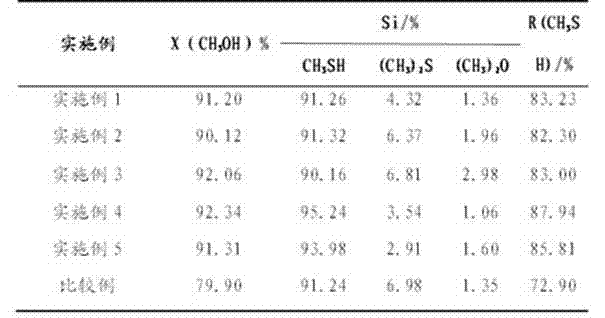

Examples

Embodiment 1

[0024] A preparation method of catalyst, comprising the following steps:

[0025] (1) Weigh 160g of analytically pure potassium tungstate and dissolve it in 500ml of water, stir evenly, and then supplement the solution to reach the equivalent of the carrier γ-Al 2 o 3 The volume of water absorption capacity. In addition, 860 g of γ-Al was dried at 120°C for 3 hours. 2 o 3 The carrier is slowly sprinkled into this impregnation solution, and after 12 hours, it is baked in a convection oven at 450°C for 2 hours to obtain K 2 WO 4 (8%) / γ-Al 2 o 3 .

[0026] (2) Weigh 1.01g of zinc chloride and dissolve it in 99ml of water, and add 0.5mol / L hydrochloric acid solution to completely dissolve zinc chloride to obtain a zinc chloride solution with a mass concentration of 1%;

[0027] (3) Mix the above zinc chloride solution with K 2 WO 4 (8%) / γ-Al 2 o 3 Mix evenly so that the mass concentration of zinc chloride in the whole mixture is 2%, to obtain the impregnation solution;...

Embodiment 2

[0031] (1) Weigh 160g of analytically pure sodium tungstate and dissolve it in 500ml of water, stir evenly, and then supplement the solution to reach the equivalent of the carrier SiO 2 The volume of water absorption capacity. In addition, take 860g of SiO which was dried at 120°C for 3h. 2 The carrier is slowly sprinkled into this impregnation solution, and after 12 hours, it is baked in a convection oven at 450 ° C for 2 hours to obtain Na 2 WO 4 (8%) / SiO 2 .

[0032] (2) Weigh 20.0g of zinc chloride and dissolve it in 80ml of water, and add 0.5mol / L hydrochloric acid solution to completely dissolve zinc chloride to obtain a zinc chloride solution with a mass concentration of 20%;

[0033] (3) Mix the above zinc chloride solution with Na 2 WO 4 (8%) / SiO 2 Mix well so that the mass concentration of zinc chloride in the whole mixture is 20%, to obtain the impregnation solution;

[0034] (4) Ultrasonic impregnation in the impregnation solution for 30 hours at 20°C;

...

Embodiment 3

[0037] (1) Weigh 160g of analytically pure cesium tungstate and dissolve it in 500ml of water, stir evenly, and then replenish the solution to a volume equivalent to the water absorption capacity of the carrier NaY molecular sieve. In addition, 860 g of NaY molecular sieve carriers dried at 120 °C for 3 h were slowly sprinkled into this impregnation solution, and after 12 h, they were roasted at 450 °C for 2 h in a convection oven to obtain Cs 2 WO 4 (8%) / NaY.

[0038] (2) Weigh 20.0g of zinc chloride and dissolve it in 80ml of water, and add 0.5mol / L hydrochloric acid solution to completely dissolve zinc chloride to obtain a zinc chloride solution with a mass concentration of 20%;

[0039] (3) Combine the above zinc chloride solution with Cs 2 WO 4 (8%) / NaY mixes, and zinc chloride mass concentration is 20% in the whole mixture, obtains dipping solution;

[0040] (4) Impregnating the impregnation solution at 60°C for 3 hours with intermittent stirring;

[0041] (5) Dry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com