Pretreatment method for enhancing BOD (biochemical oxygen demand) absolute value of chemical waste acid

A pretreatment, absolute value technology, applied in the field of water treatment, to achieve the effect of increasing the absolute value of BOD, easy operation, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

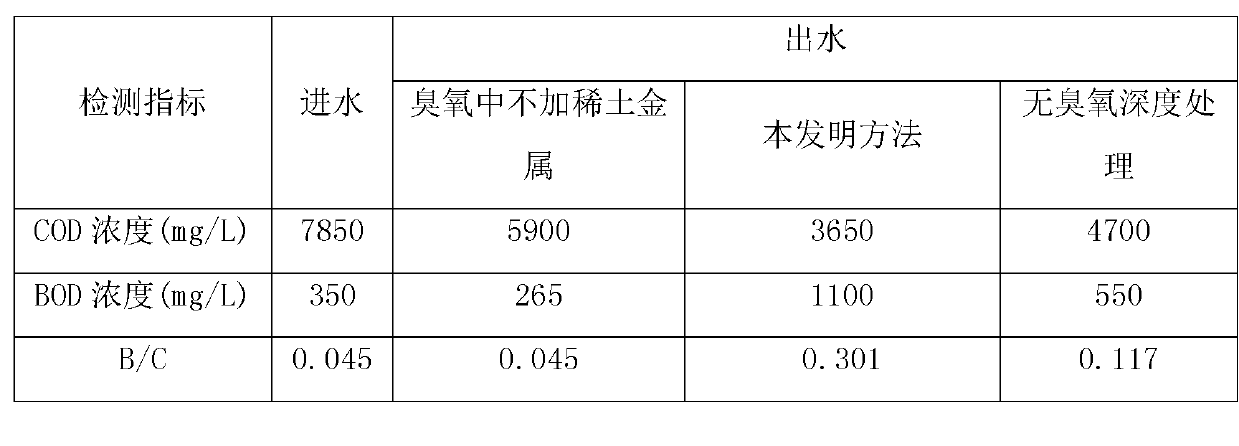

[0025] 100 tons / day chemical waste acid treatment project in a printing and dyeing factory.

[0026] The measured water quality of the chemical waste acid raw water is shown in the following table:

[0027] item number

project

measured value

1

pH value

0.42

2

COD Cr

7850mg / L

3

BOD 5

350mg / L

4

B / C

0.045

5

Chroma

1200 times

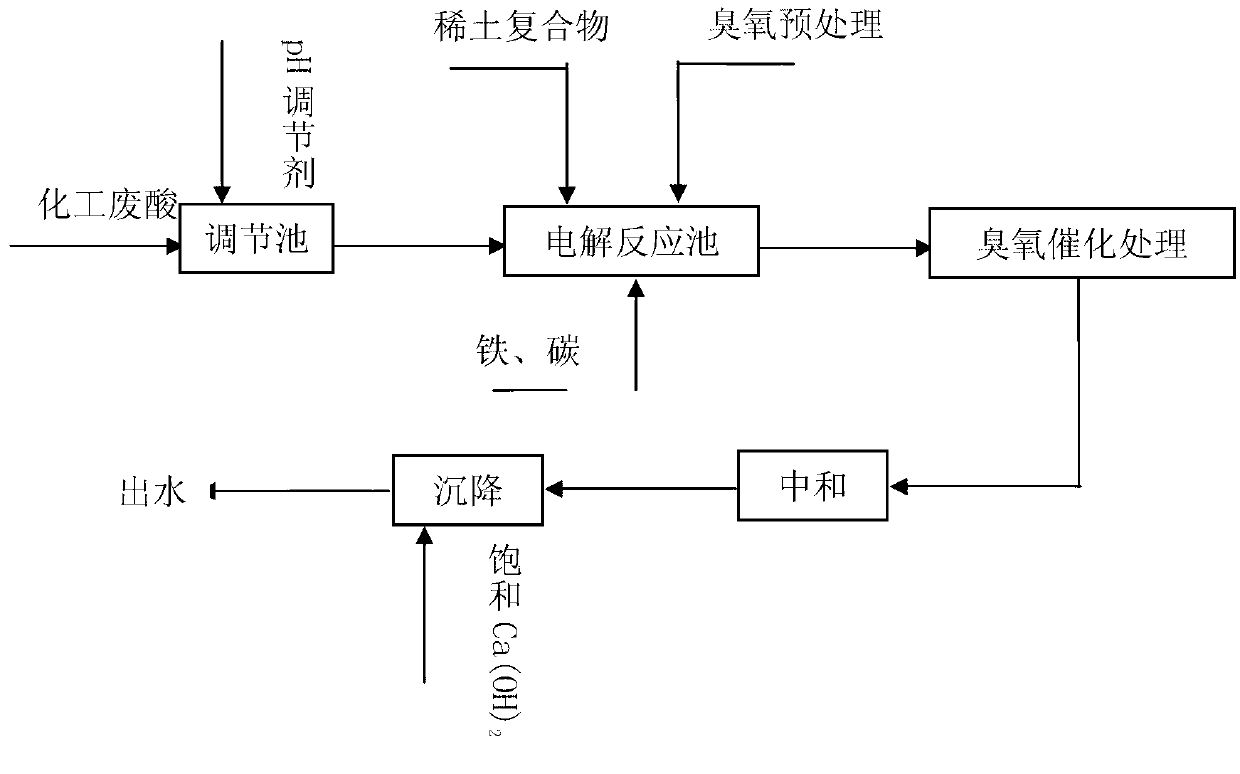

[0028] according to figure 1 Shown flow process, water quality is adjusted in the present embodiment:

[0029] The chemical waste acid in the printing and dyeing factory enters the regulating tank through the pipeline to adjust the water quality and balance the water volume, so that the flow and parameters of the chemical waste acid of different properties from all over the printing and dyeing factory can be fully adjusted to facilitate the treatment of subsequent units, and hydrogen is added to the regulating tank Sodium oxide solution, adjust the pH ...

Embodiment 2

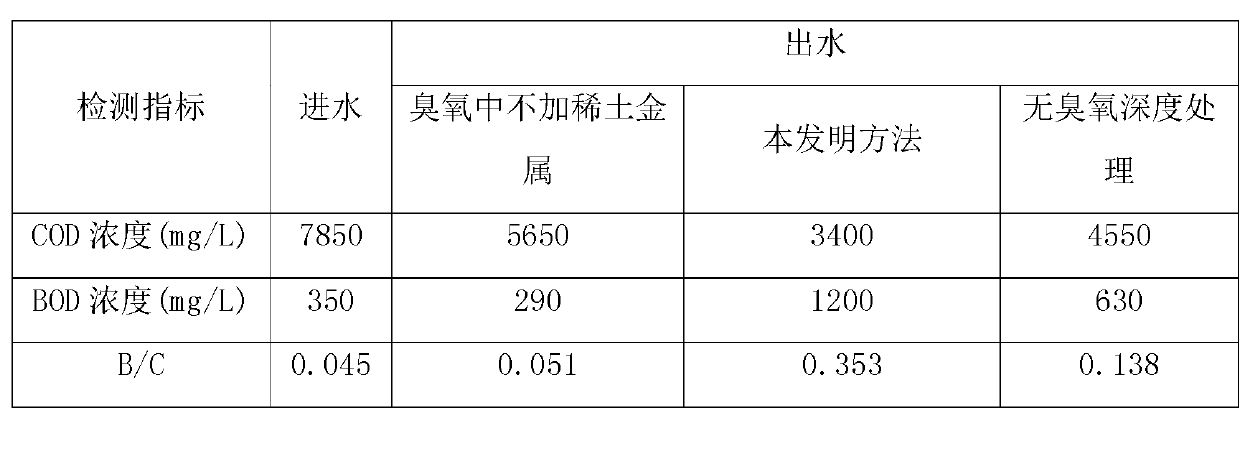

[0039] The raw water quality of chemical waste acid is the same as that of Example 1 above.

[0040] 1) Regulate water quality. The chemical waste acid in the printing and dyeing factory enters the regulating tank through the pipeline to adjust the water quality and balance the water volume, so that the flow and parameters of the chemical waste acid of different properties from all over the printing and dyeing factory can be fully adjusted to facilitate the treatment of subsequent units, and hydrogen is added to the regulating tank Sodium oxide solution, adjust the pH value to 2.5.

[0041] 2) Ozone pretreatment of waste acid: After adding 780 mg / L rare earth compound to the adjusted chemical waste acid, pass through ozone for pre-reaction for 5 minutes. At this time, the pH of the waste acid solution is 2.7.

[0042] 3) Rare earth-iron carbon micro-electrolysis. Add 7850 mg / L of activated iron filings and 520 mg / L of carbon particles into the micro-electrolytic cell. Open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com