Method for preparing copper chlorophyll and sodium salt thereof from silkworm excrement

A technology of copper chlorophyll and silkworm sand, applied in organic chemistry and other directions, can solve the problems of high explosion-proof requirements in production workshops, affecting the content of finished products, damage, etc., to increase production safety, reduce extraction costs, and simplify the operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

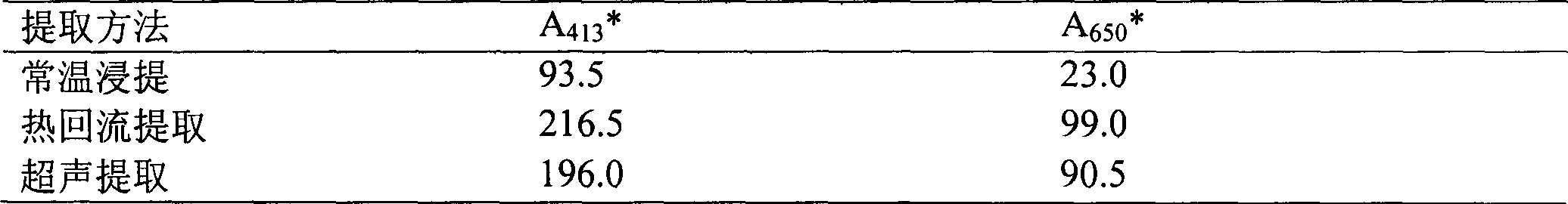

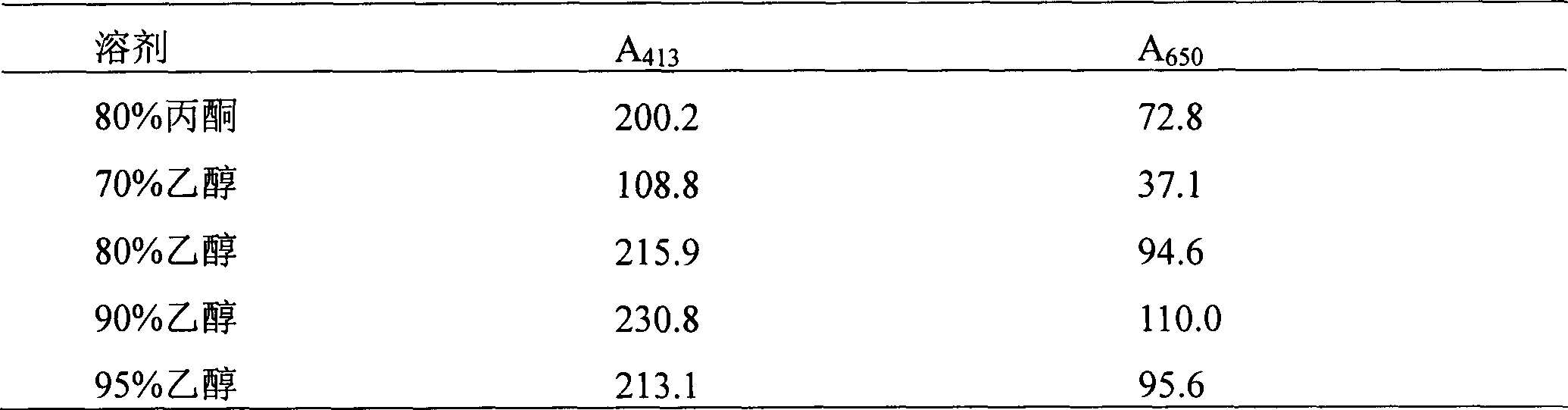

[0033] 2.1 Preparation of silkworm excrement chlorophyll extract

[0034] Weigh 100g silkworm excrement, add water to moisten it, add 800ml of 90% ethanol, add 12mL of 10% CuSO 4 solution, adjusted to pH 2-3 with hydrochloric acid, and extracted by heating at reflux at 80°C for 6 hours. After filtering, the extract was refrigerated and left standing, and then filtered again to obtain the extract.

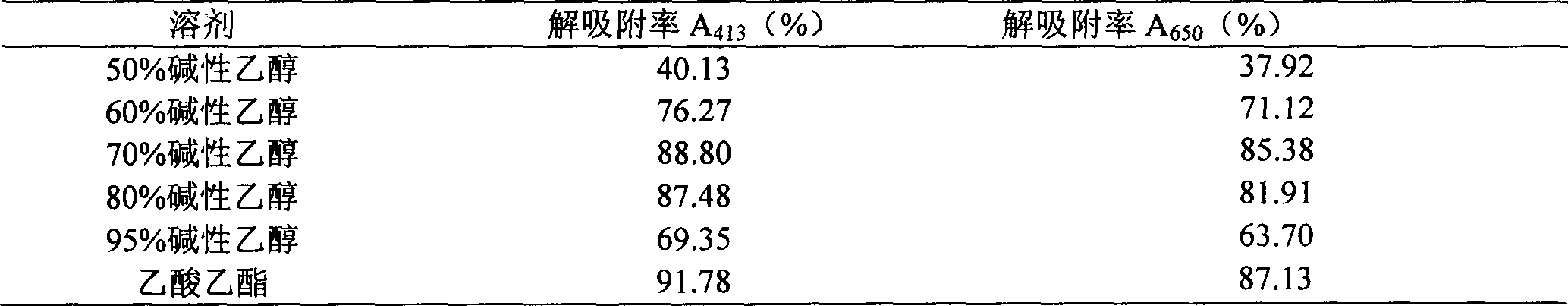

[0035] 2.2 Determination of desorption rate of different solvents

[0036] Accurately weigh 6 parts of 0.1 g of NaOH, add 50%, 60%, 70%, 80%, and 95% ethanol respectively to dissolve, and configure alkaline ethanol solutions with different alcohol concentrations.

[0037] Weigh 6 g of pretreated D101 dry resin, put it in a conical flask, and pipette 150.00 mL of chlorophyll extract precisely, 120r min -1 Shake for 24h, filter after full adsorption. Weigh 6 parts of the saturated adsorption resin, each 1.000g, and put them into 6 Erlenmeyer flasks, and add 50%, 60%, 70%, 80%, 95%...

Embodiment 2

[0046] Take 1.0kg of silkworm excrement, wash it with water, remove the sediment, add 4L of 95% ethanol, add hydrochloric acid to adjust pH1, add 10g of CuSO 4 Dissolved in a small amount of water and added to the extract, heated to reflux at 70°C for 4 hours, filtered to obtain the extract. The extract was refrigerated for 24 hours, filtered to obtain the sample solution. Take 330g of HPD-100 macroporous resin and add the chlorophyll extract of silkworm excrement as a sample, first elute with water and 30% ethanol to remove impurities until the eluate is basically colorless, then discard the eluate. Another 70% ethanol was taken, and NaOH was added to adjust the pH to 10 to become alkaline ethanol, which was eluted with 3.3Kg alkaline ethanol, and the eluate was collected. The eluate was concentrated to an alcohol concentration of 20-30%, and the insoluble matter was filtered. Add acid to adjust the pH to 2-3, filter the precipitated precipitate, wash with water until the p...

Embodiment 3

[0048] Take 1.0kg of silkworm excrement, wash it with water, remove the sediment, add 10L of ethanol with a concentration of 80%, add hydrochloric acid to adjust pH4, add 30g of CuSO 4 Dissolve it in a small amount of water and add it to the extract, heat and reflux at 80°C for 6 hours, and filter to obtain the extract. The extract was refrigerated and allowed to stand for 12 hours, then filtered to obtain the sample solution. Take 1000g of NKA macroporous resin and sample the chlorophyll extract from silkworm excrement, first elute with water and 50% ethanol to remove impurities until the eluate is basically colorless, then discard the eluate. Another 60% ethanol was taken, and NaOH was added to adjust the pH to 11 to become alkaline ethanol, which was eluted with 3Kg alkaline ethanol, and the eluate was collected. The eluate was concentrated to an alcohol concentration of 10-20%, and the insoluble matter was filtered. Add acid to adjust the pH to 2-3, filter the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com