Attapulgite grafted polymethyl methacrylate hybrid particle and preparation method thereof

A technology of polymethyl methacrylate and attapulgite, which is applied in the treatment of dyed organosilicon compounds, dyed polymer organic compounds, fibrous fillers, etc., can solve the problem of inability to form a hybrid network structure and low grafting rate , easy aggregation and other problems, to avoid the reduction of the activity of the initiator group, to overcome the effect of low grafting rate and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Disperse 10g of attapulgite containing impurities in 100mL of distilled water, disperse by ultrasonic for 60min, add 0.2g of sodium hexametaphosphate, heat to 70°C, stir for 4h, pour out the upper suspension, remove the solvent, wash several times, vacuum dry, and grind Sieve to obtain purified attapulgite.

[0031] Disperse the purified attapulgite in 1 mol / L hydrochloric acid and vibrate ultrasonically for 6 minutes, remove the solvent after standing for 24 hours, wash until neutral, dry in vacuum, grind and sieve to obtain acid-activated attapulgite.

[0032] Take 4g of acid-activated attapulgite soil and disperse it in 100mL of toluene, ultrasonically disperse for 60min, add 8g of γ-aminopropyltriethoxysilane dropwise under stirring condition, after the dropwise addition, heat to 80°C, react for 12h, and the reaction ends Afterwards, the solvent is removed, vacuum-dried, ground and sieved to obtain aminoalkoxysilane-modified organic attapulgite.

[0033]Take 0.5g o...

Embodiment 2

[0035] Disperse 10g of attapulgite containing impurities in 200mL of distilled water, ultrasonically disperse for 30min, add 0.2g of sodium hexametaphosphate, heat to 80°C, stir for 6h, pour out the upper suspension, remove the solvent, wash several times, vacuum dry, and grind Sieve to obtain purified attapulgite.

[0036] Disperse the purified attapulgite in 0.5 mol / L dilute sulfuric acid and vibrate it ultrasonically for 30 minutes, remove the solvent after standing for 24 hours, wash until neutral, dry in vacuum, grind and sieve to obtain acid-activated attapulgite.

[0037] Take 4g of acid-activated attapulgite soil and disperse it in 150mL of toluene, ultrasonically disperse for 30min, add 4g of γ-aminopropyltrimethoxysilane dropwise under stirring condition, after the dropwise addition, heat to 110°C, react for 10h, after the reaction , remove the solvent, dry in vacuum, grind and sieve to obtain aminoalkoxysilane modified organic attapulgite.

[0038] Disperse 0.5g of...

Embodiment 3

[0040] Disperse 10g of impurity-containing attapulgite in 250mL of distilled water, disperse by ultrasonic for 40min, add 0.1g of sodium hexametaphosphate, heat to 60°C, stir for 5h, pour out the upper suspension, remove the solvent, wash several times, vacuum-dry, and grind Sieve to obtain purified attapulgite.

[0041] Disperse the purified attapulgite in 1 mol / L hydrochloric acid and vibrate ultrasonically for 40 minutes, let it stand for 24 hours, remove the solvent, wash until neutral, dry in vacuum, grind and sieve to obtain acid-activated attapulgite.

[0042] Take 4g of acid-activated attapulgite soil and disperse it in 100mL of xylene, disperse it ultrasonically for 40min, add 8g of N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane dropwise under stirring condition, drop After the addition, heat to 140°C and react for 6 hours. After the reaction, remove the solvent, dry in vacuum, grind and sieve to obtain the aminoalkoxysilane-modified organic attapulgite.

[0043...

PUM

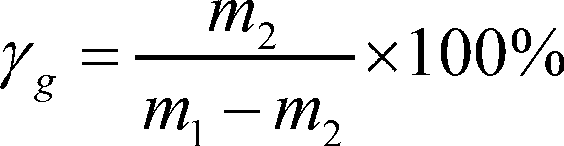

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com