Basic polyarylene ether ionomer material with microphase separation structure and its preparation and application

A technology of microphase separation and polyarylether, which is applied in the field of basic polyarylether ionomer and its preparation, can solve the problems of decreased alcohol resistance performance, decreased ion conductivity, and decreased long-term chemical stability in the working environment. Enhanced ionic conductivity, high ionic conductivity, and good ion-conducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present embodiment adopts following method to prepare basic polyarylether ionomer:

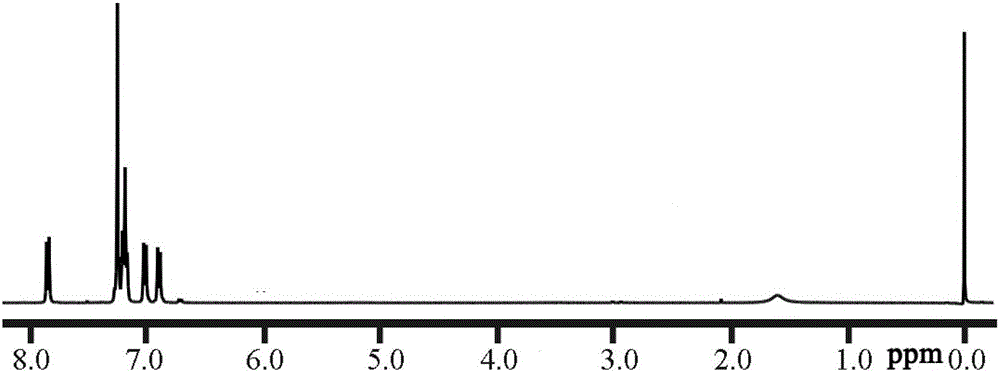

[0054] 1) Synthesis of hydrophilic segment: 7.5183g (21.333mmol) (ie m+1=16) of bis(4,4'-hydroxyphenyl) diphenylmethane, 5.085g (20mmol) (ie m=15) ) of dihalogen monomer a1, 4.4417g (32.142mmol) of anhydrous potassium carbonate, 30mL N,N-dimethylacetamide and 30mL toluene were added to a three-necked flask, and under nitrogen protection, the temperature of the oil bath was 140°C under reflux water for 3 hours, then warmed up to 180°C, after 12 hours of reaction, add 0.3759g (1.0666mmol) (ie 5mol% (m+1)) of bis(4,4'-hydroxyphenyl) diphenylmethane, in Continue to react at 180°C for 3 hours, then cool to room temperature, precipitate the reaction solution in 60mL of 1:1 (v / v) methanol / 3% concentrated hydrochloric acid solution, dry the crude product at 80°C in vacuum for 24 hours, and then use chloroform solvent Dissolve, pass through diatomaceous earth, precipitate in methanol, colle...

Embodiment 2

[0079] Except for the following features, other steps and testing methods of the preparation method of the present embodiment are the same as in Example 1:

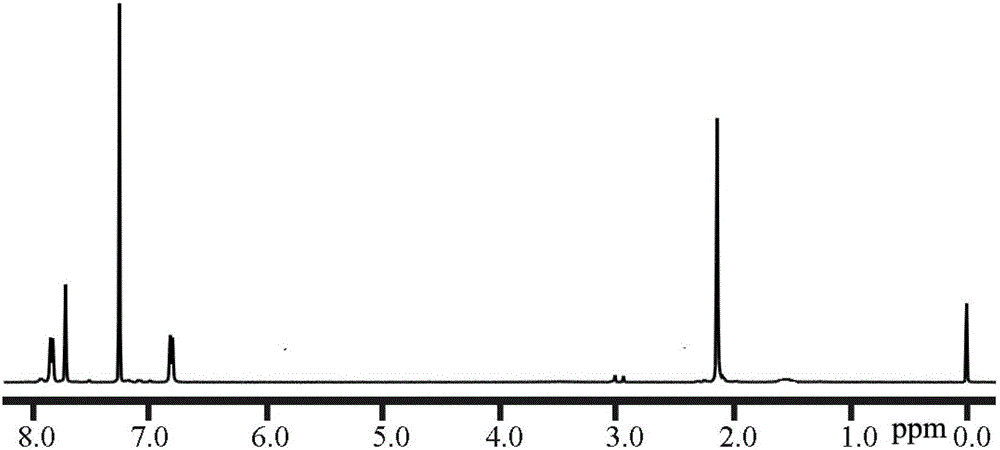

[0080] When preparing the hydrophilic segment polymer, bis(4,4'-hydroxyphenyl) diphenylmethane 7.440g (21.111mmol), dihalogen monomer b1 (where X is F) 4.364g (20mmol), m= 18, 27mL of N,N-dimethylacetamide, 30mL of toluene, under the protection of nitrogen, the temperature of the oil bath is 150°C and the water is refluxed for 6 hours, then the temperature is raised to 200°C, after 12 hours of reaction, add 5mol% ( m+1) of bis(4,4'-hydroxyphenyl)diphenylmethane, continue to react at 200°C for 3 hours, then cool to room temperature, and dissolve the reaction solution in 60mL of 1:1 (v / v) methanol / 3% concentrated hydrochloric acid solution precipitation, the crude product was dried in vacuum at 80°C for 24 hours, then dissolved in chloroform solvent, passed through diatomaceous earth, precipitated in methanol, collected th...

Embodiment 3

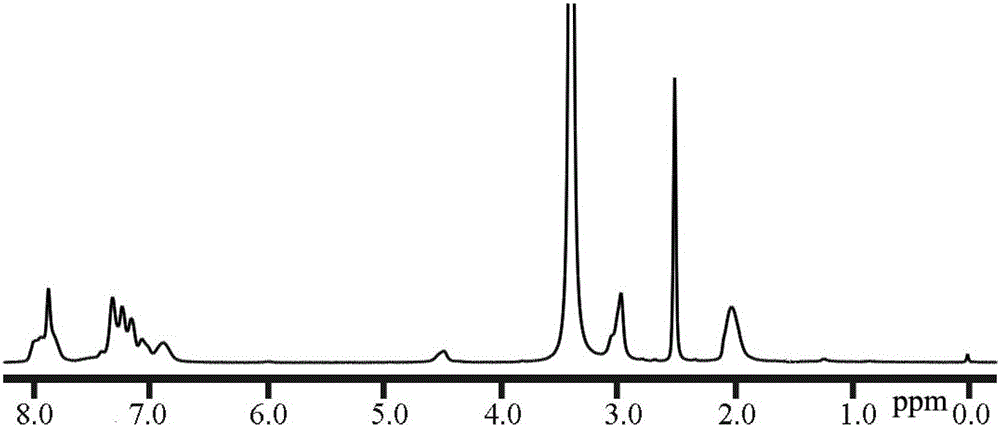

[0105] Except for the following features, other steps and testing methods of the preparation method of the present embodiment are the same as in Example 2:

[0106] When preparing the hydrophilic segment polymer, the reactant is 7.552g (21.4285mmol) of bis(4,4'-hydroxyphenyl) diphenylmethane, 8.8288g (20mmol) of dihalogen monomer c1 (where X is Cl) , m=14, N,N-dimethylacetamide is 37mL, and toluene is 60mL.

[0107] The dihalogen monomer in this embodiment has the following structure:

[0108]

[0109] Wherein X is Cl;

[0110] The hydrophilic segment of the present embodiment has the following structure:

[0111]

[0112] has the following structure:

[0113]

[0114] When preparing hydrophobic segment polymers, the reactant dihalogen monomer c1 (where X is Cl) 8.8799g (21.4285mmol), dihydroxy aromatic monomer I5.0054g (20mmol), n=14, dimethyl sulfoxide 32mL , Toluene 60mL.

[0115] The dihydroxyaromatic monomer of the present embodiment has the following stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com