Polar plate-free micro-methanol fuel cell membrane electrode and preparation method thereof

A methanol fuel cell and membrane electrode technology, which is applied in the direction of fuel cells, battery electrodes, fuel cell components, etc., can solve the problems of large volume, achieve the effect of improving performance, increasing power density, and simplifying the overall structure of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

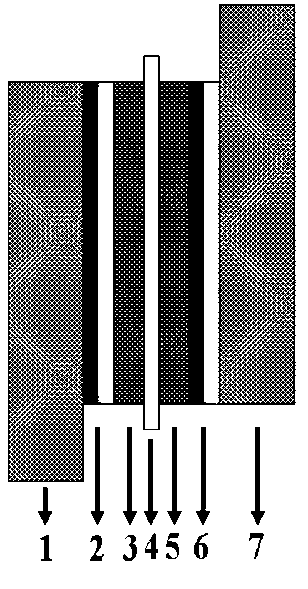

[0019] Specific implementation mode one: as figure 1 As shown, the electrodeless plate micro-methanol fuel cell membrane electrode of this embodiment is composed of an anode stainless steel felt half electrode, a proton exchange membrane 4 and a cathode stainless steel felt half electrode, and the anode stainless steel felt half electrode is composed of an anode stainless steel felt 1, an anode micropore layer 2 and anodic catalytic layer 3, the anode catalytic layer 3 is located on the left side of the proton exchange membrane 4, the left side of the anode catalytic layer 3 is followed by the anode microporous layer 2 and the anode stainless steel felt 1, and the cathode stainless steel felt half electrode consists of The cathode catalytic layer 5, cathode microporous layer 6 and cathode stainless steel felt 7 are composed. The cathode catalytic layer 5 is located on the right side of the proton exchange membrane 4, and the right side of the cathode catalytic layer 5 is the ca...

specific Embodiment approach 2

[0022] Specific implementation mode 2: In this implementation mode, a non-polar plate micro-methanol fuel cell membrane electrode is prepared according to the following method:

[0023] 1. Cutting and cleaning of stainless steel felt:

[0024] Cut the stainless steel felt into a rectangle that matches the size of the fixture, ultrasonically clean it with ultrapure water for 5 minutes to remove water-soluble dirt, then ultrasonically clean it with anhydrous ethanol solution for 30 minutes to remove organic surface dirt, and then dry it at 80°C.

[0025] 2. Preparation of microporous layer slurry:

[0026] Add a certain amount of PTFE into the ethylene glycol solvent and ultrasonically vibrate for 5 minutes, then add nano-scale carbon powder 5 to 9 times the mass of PTFE, and add an appropriate amount of ethylene glycol to completely immerse the carbon powder. The slurry in the test tube was stirred with a magnetic stirrer for 1 min, then ultrasonically oscillated for 30 min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com