Supported copper-based metal catalyst with high dispersion as well as preparation method and application thereof

A supported catalyst technology, applied in the preparation of hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of large metal oxide particle size, easy collapse of laminates, and poor dispersion and other problems, to achieve the effect of preventing sintering aggregation, improving dispersion and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

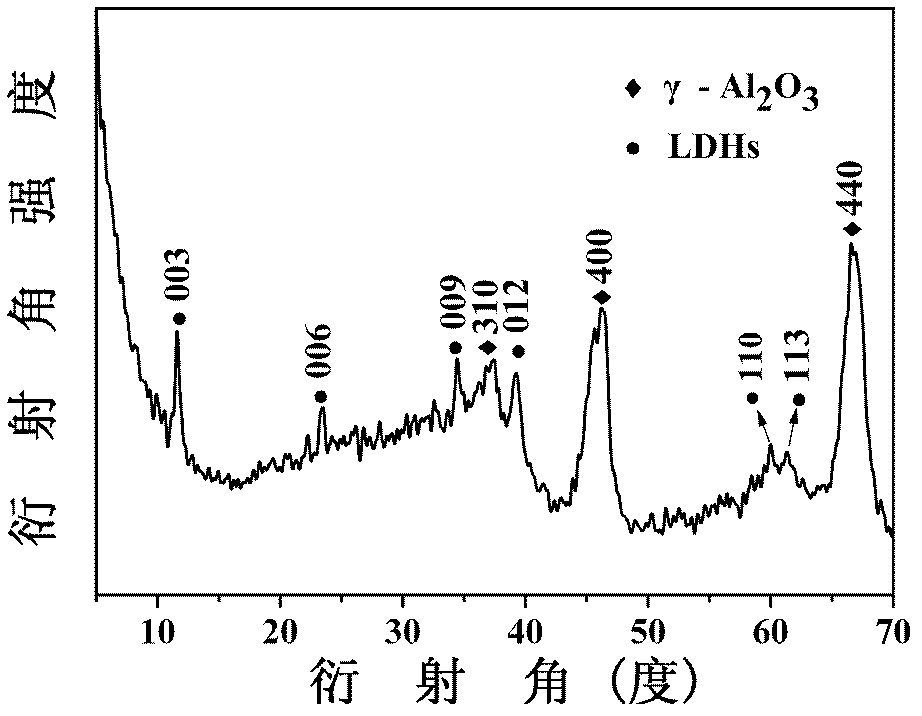

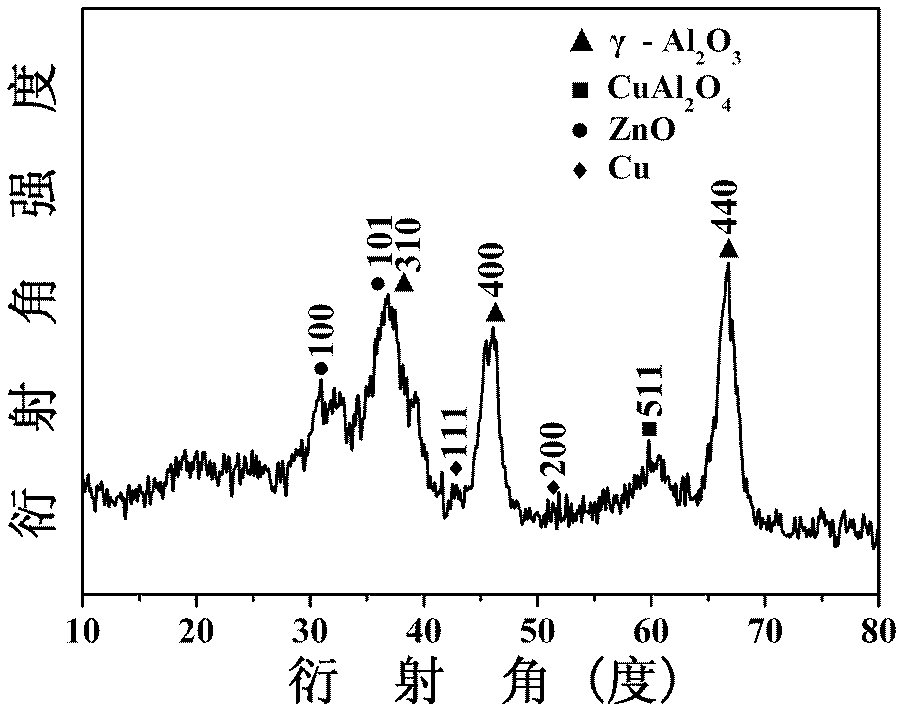

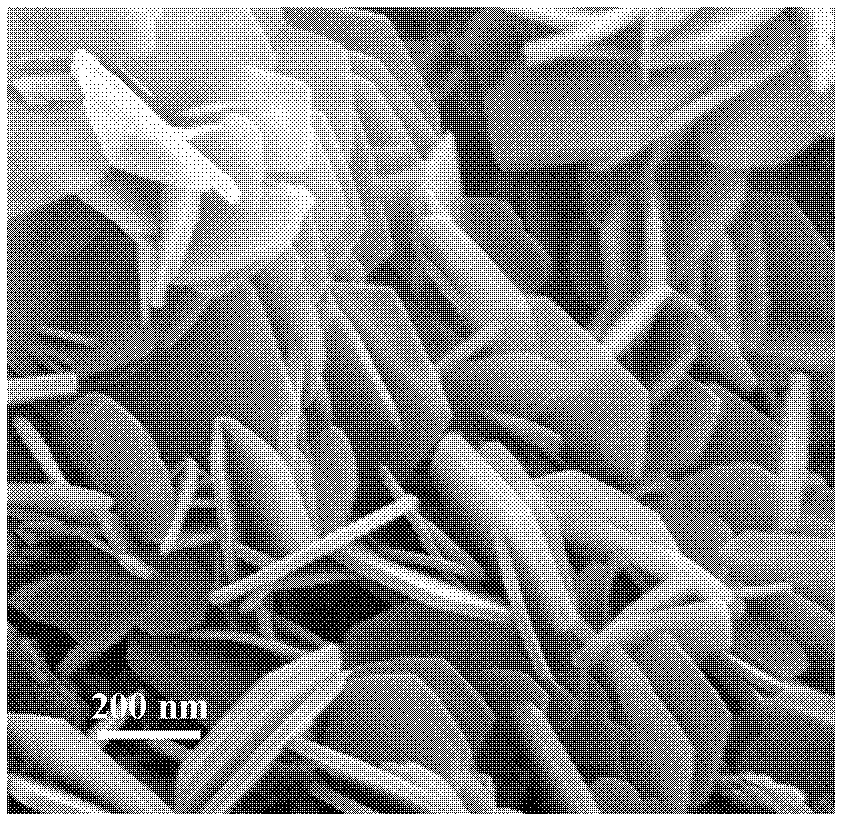

[0025] Weigh 0.6444g of Cu(NO 3 ) 2 ·6H 2 O and 1.5866g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 4ml deionized water to prepare Cu(NO 3 ) 2 and Zn(NO 3 ) 2 The mixed salt solution, and the mol ratio of copper nitrate and zinc nitrate is 0.5: 1; Then add 0.9614g urea to it again. Weigh 2g spherical γ-Al 2 o 3 The carrier was added to the above-prepared solution, soaked for 1 hour, transferred to a 25mL polytetrafluoroethylene liner and placed in a high-pressure reactor, and reacted at 100°C for 10 hours. Secondary to neutral, dry in an oven at 70°C for 12 hours to obtain in-situ supported copper-based hydrotalcite CuZnAl-LDHs / γ-Al 2 o 3 . The resulting CuZnAl-LDHs / γ-Al 2 o 3 Placed in a muffle furnace for calcination, raised to 500°C at a heating rate of 5°C / min and held for 6 hours, and cooled naturally to room temperature to obtain the corresponding in-situ supported composite metal oxide. Then put the obtained in-situ supported composite metal oxide in a tubul...

Embodiment 2

[0028] Weigh 0.9664g of Cu(NO 3 ) 2 ·6H 2 O and 1.0256g of Mg(NO 3 ) 2 ·6H 2 O was dissolved in 4ml deionized water to prepare Cu(NO 3 ) 2 and Mg(NO 3 ) 2 The mixed salt solution, and the mol ratio of copper nitrate and magnesium nitrate is 1: 1; Then add 1.4422g urea to it again. Weigh 2g spherical γ-Al 2 o 3 The carrier was added to the above-prepared solution, soaked for 2 hours, transferred to a 25mL polytetrafluoroethylene liner and placed in a high-pressure reactor, and reacted at 120°C for 14 hours. After the reaction was completed, it was naturally cooled to room temperature. Secondary to neutral, dried in an oven at 60°C for 16 hours to obtain in-situ supported copper-based hydrotalcite CuMgAl-LDHs / γ-Al 2 o 3 . The obtained CuMgAl-LDHs / γ-Al 2 o 3 Placed in a muffle furnace for calcination, raised to 600°C at a rate of 10°C / min and held for 7 hours, and cooled naturally to room temperature to obtain the corresponding in-situ supported composite metal oxi...

Embodiment 3

[0031] Weigh 0.4832g of Cu(NO 3 ) 2 ·6H 2 O and 1.7462g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 4ml deionized water to prepare Cu(NO 3 ) 2 and Co(NO 3 ) 2 The mixed salt solution, and the mol ratio of copper nitrate and zinc nitrate is 0.3: 1; Then add 1.6825g urea to it again. Weigh 2g spherical γ-Al 2 o 3 The carrier was added to the above-prepared solution, soaked for 4 hours, transferred to a 25mL polytetrafluoroethylene liner and placed in a high-pressure reactor, and reacted at 110°C for 24 hours. After the reaction was completed, it was naturally cooled to room temperature. Secondary to neutral, dried in an oven at 30°C for 10 hours to obtain in-situ supported copper-based hydrotalcite CuCoAl-LDHs / γ-Al 2 o 3 . The resulting CuCoAl-LDHs / γ-Al 2 o 3 Placed in a muffle furnace for calcination, raised to 700°C at a heating rate of 5°C / min and held for 5 hours, and cooled naturally to room temperature to obtain the corresponding in-situ supported composite meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com