Large-diameter flange and preparation process thereof

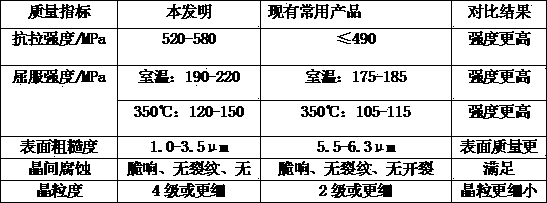

A manufacturing process and large-diameter technology, applied in the field of large-diameter flanges and their manufacturing processes, can solve the problems of not meeting the requirements of large-diameter flanges, low tensile strength of flanges, small surface roughness, etc., and achieve defects The effects of obvious relief, grain refinement, and uniform structure refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The mass percentage of the large diameter flange of this embodiment is: C: 0.65%, Si: 0.25%, Mn: 0.85%, Ni: 9%, Cr: 2%, Nb: 0.15%, Cu: 0.85 %, N: 0.02%, Mo: 0.13%, Al: 0.2%, S: 0.07%, Ti: 0.03%, V: 0.02%, B: 0.002%, lanthanide rare earth: 6%, the balance is Fe; The mass percentages of the components of the lanthanide rare earths are: lanthanum: 20%, cerium: 25%, samarium: 16%, neodymium: 14%, gadolinium: 2%, praseodymium: 17%, dysprosium: 5%, and the remaining lanthanides :1%.

[0026] The manufacturing process of the large-diameter flange in this embodiment is carried out according to the following procedures: billet blanking-forging-forging size and surface inspection-heat treatment-mechanical rough machining-ultrasonic inspection-mechanical performance test-mechanical finishing to the required shape and size -Clean coating; Among them, billet blanking, forging, forging size and surface inspection, mechanical rough machining, ultrasonic inspection, mechanical perform...

Embodiment 2

[0034] The mass percentage of the large diameter flange of this embodiment is: C: 0.45%, Si: 0.30%, Mn: 0.95%, Ni: 11%, Cr: 3%, Nb: 0.20%, Cu: 0.95 %, N: 0.03%, Mo: 0.14%, Al: 0.3%, S: 0.08%, Ti: 0.04%, V: 0.03%, B: 0.003%, lanthanide rare earth: 7%, the balance is Fe; The mass percentages of the lanthanide rare earth components are: lanthanum: 24%, cerium: 20%, samarium: 15%, neodymium: 15%, gadolinium: 3%, praseodymium: 16%, dysprosium: 6%, and the remaining lanthanides :1%.

[0035] The manufacturing process of the large-diameter flange in this embodiment is carried out according to the following procedures: billet blanking-forging-forging size and surface inspection-heat treatment-mechanical rough machining-ultrasonic inspection-mechanical performance test-mechanical finishing to the required shape and size -Clean coating; Among them, billet blanking, forging, forging size and surface inspection, mechanical rough machining, ultrasonic inspection, mechanical performance te...

Embodiment 3

[0043] The mass percentage of the large diameter flange of this embodiment is: C: 0.55%, Si: 0.25%, Mn: 0.90%, Ni: 10%, Cr: 2%, Nb: 0.18%, Cu: 0.90 %, N: 0.04%, Mo: 0.15%, Al: 0.2%, S: 0.09%, Ti: 0.03%, V: 0.02%, B: 0.004%, lanthanide rare earth: 8%, and the balance is Fe; The mass percentages of the lanthanide rare earth components are: lanthanum: 20-24%, cerium: 20-25%, samarium: 14-16%, neodymium: 14-16%, gadolinium: 2-4%, praseodymium: 16- 18%, dysprosium: 5-6%, other lanthanides: 1-3%.

[0044] The manufacturing process of the large-diameter flange in this embodiment is carried out according to the following procedures: billet blanking-forging-forging size and surface inspection-heat treatment-mechanical rough machining-ultrasonic inspection-mechanical performance test-mechanical finishing to the required shape and size -Clean coating; Among them, billet blanking, forging, forging size and surface inspection, mechanical rough machining, ultrasonic inspection, mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com