Non-carbonate based novel?electrolyte solution?system used for spinel lithium titanate energy storage type lithium ion secondary battery

A technology for lithium lithium titanate and secondary batteries, which is applied in the field of new non-carbonate-based electrolyte systems for lithium-ion secondary batteries with spinel lithium titanate energy storage, and can solve the problems affecting the service life and performance of batteries. Problems such as flatulence, to achieve the effect of prolonging service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

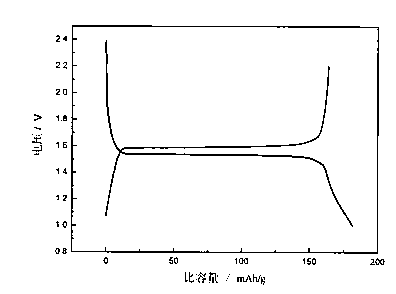

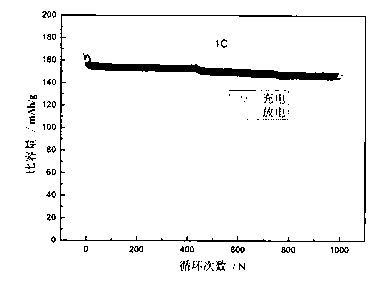

[0010] Li / Li 4 Ti 5 o 12 The system simulates a half-cell, and the specific process is as follows:

[0011] Weigh a certain amount of Li according to the weight percentage 8:1:1 4 Ti 5 o 12 , acetylene black and polyvinylidene fluoride (PVDF), using pyrrolidone as a dispersant, stir and mix them evenly. Using aluminum foil as a current collector, the mixed slurry was rolled into a pole piece with a thickness of 50 microns by a rolling machine. The electrolyte adopts organic electrolyte TEGDME, the electrolyte is 1mol / L LiFSI, and the water content of the obtained electrolyte is lower than 15ppm.

[0012] The battery assembly uses a standard button cell CR2032, and the separator is glass fiber. The entire assembly process is completed in an argon glove box with a moisture content below 0.5ppm. Test results such as figure 1 with 2 And shown in Table 1.

Embodiment 2

[0014] Li / Li 4 Ti 5 o 12 The system simulates a half-cell, and the specific process is as follows:

[0015] Weigh a certain amount of Li according to the weight percentage 8:1:1 4 Ti 5 o 12 , acetylene black and polyvinylidene fluoride (PVDF), using pyrrolidone as a dispersant, stir and mix them evenly. Using copper foil as a current collector, the mixed slurry was rolled into a pole piece with a thickness of 50 microns by a rolling machine. The electrolyte is organic electrolyte TGDME, the electrolyte is 1mol / L LiTFSI, and the water content of the obtained electrolyte is lower than 10ppm.

[0016] The battery assembly uses a standard button cell CR2032, and the separator is glass fiber. The entire assembly process is completed in an argon glove box with a moisture content below 0.5ppm. The test results are shown in Table 1.

Embodiment 3

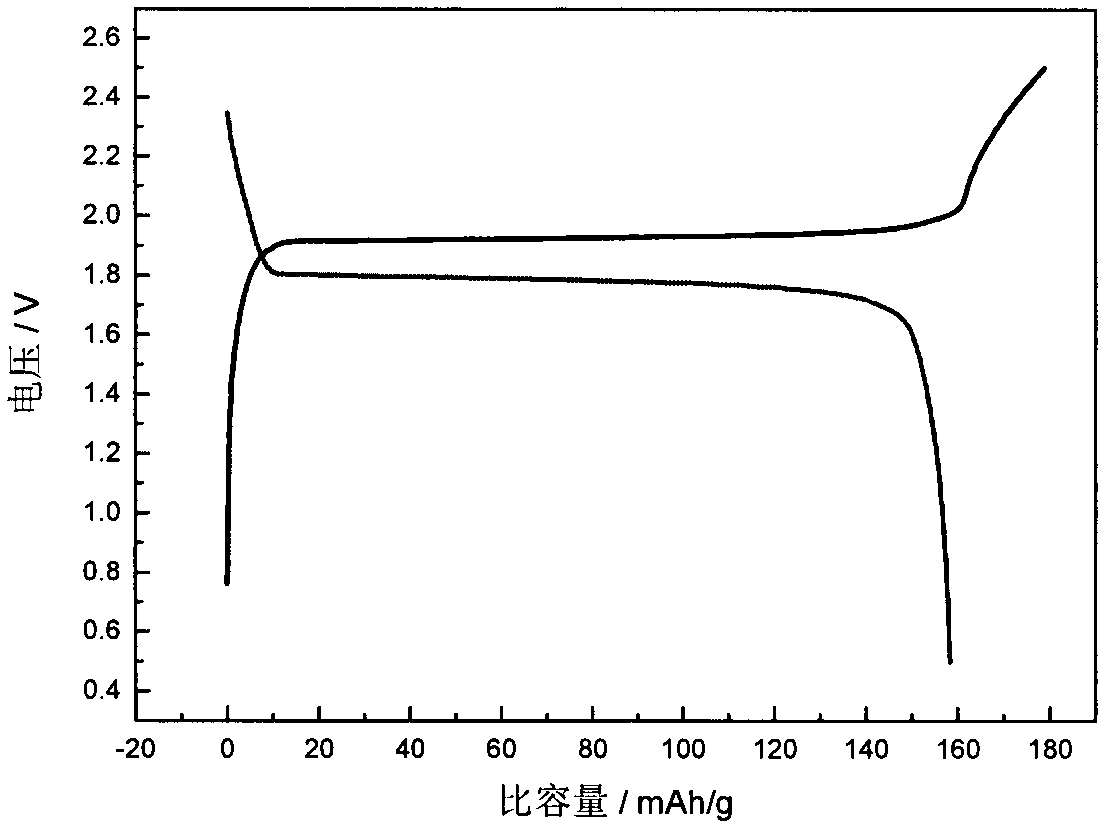

[0018] Li / LiFePO 4 The system simulates a half-cell, and the specific process is as follows:

[0019] Weigh a certain amount of LiFePO according to the weight percentage 8:1:1 4 , acetylene black and polyvinylidene fluoride (PVDF), using pyrrolidone as a dispersant, stir and mix them evenly. Using aluminum foil as a current collector, the mixed slurry was rolled into a pole piece with a thickness of 50 microns by a rolling machine. The electrolyte adopts organic electrolyte DGDME, the electrolyte is 1mol / L LiFSI, and the water content of the obtained electrolyte is lower than 15ppm.

[0020] The battery assembly uses a standard button cell CR2032, and the separator is glass fiber. The entire assembly process is completed in an argon glove box with a moisture content below 0.5ppm. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com