High-efficiency seed coating

A technology of coating agent and seed, applied in the field of seed coating agent, can solve problems such as environmental pollution, achieve the effects of improving pesticide efficacy, improving microenvironment, and improving seedling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The inventor has carried out field test in Tianjin.

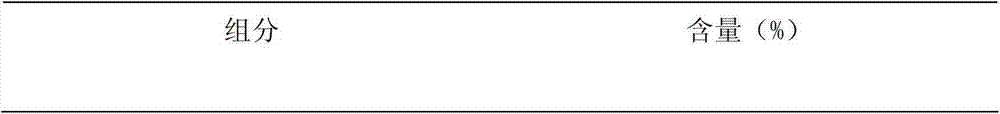

[0023] The test site is the test field in Tianjin Development Zone. The test soil is sandy soil with average fertility. The components of the seed coating agent used in the present invention (both are weight percentages) are:

[0024] Take 77% of γ-polyglutamic acid, 18% of polyvinyl alcohol, 2% of hydroxypropyl methylcellulose and methyl cellulose (mass ratio 5:1), surfactant OP 20 1%, 0.5% gentian violet, 0.2% carbendazim, 0.3% thiram, 1% carbofuran. Prepare the coating agent, take 100g and coat 5 kg of corn seeds, and let it dry naturally.

[0025] The tested corn, its seed quality testing results: purity ≥ 95.0%, clarity ≥ 98.0%, germination rate ≥ 80%, test A is a commercially available seed coating agent (16.8% multi-for-gram suspension seed coating agent, of which more than Bacillus 3.8%, thiram 6%, carbofuran 7%), B is the above seed coating agent, C is the blank control.

[0026] The experiment was rando...

Embodiment 2

[0040] The components of the seed coating agent used in the present invention (all are percentages by weight) are:

[0041] Take 70% of γ-polyglutamic acid, 26% of polyvinyl alcohol, 1.5% of hydroxypropyl methylcellulose and methylcellulose (mass ratio 5:1), surfactant OP 20 0.1%, 0.5% gentian violet, 0.2% carbendazim, 0.8% thiram, 0.9% carbofuran. Prepare the coating agent, take 100g and coat 5 kg of corn seeds, and let it dry naturally. Test corn is with specific implementation example 1. B is the above-mentioned seed coating agent, and C is the blank control. Other conditions are with embodiment 1.

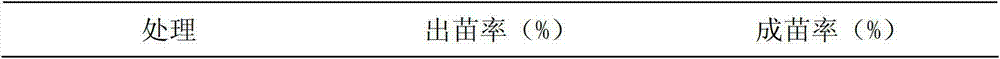

[0042] Seedling emergence rate of each treatment in table 4

[0043]

[0044]

[0045] As can be seen from Table 4, the highest seedling emergence rate is that the B seed coating is 87.9%; the second is the A seed coating is 84.3%, and the third is that the blank control without coating is 83.5%. Moreover, the seedlings of the B seedlings emerged neatly, about 2 days...

Embodiment 3

[0056] The components of the seed coating agent used in the present invention (all are percentages by weight) are:

[0057] Take 65% of γ-polyglutamic acid, 30% of polyvinyl alcohol, 2% of hydroxypropyl methylcellulose and methylcellulose (mass ratio 5:1), surfactant OP 20 1%, 0.5% gentian violet, 0.2% carbendazim, 0.3% thiram, 1% carbofuran. Prepare the coating agent, take 100g and coat 5 kg of corn seeds, and let it dry naturally.

[0058] For testing corn with embodiment 1. B is the above-mentioned seed coating agent, and C is the blank control. Other conditions are with embodiment 1.

[0059] Seedling emergence rate of each treatment in table 7

[0060]

[0061]

[0062] As can be seen from Table 7, the highest seedling emergence rate is 87.6% of the B seed coating; followed by the A seed coating of 85.7%, and the third is the non-coated blank control of 84.9%. Moreover, the seedlings of the B seedlings emerged neatly, about 2 days earlier than the control seedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com