Manufacturing method of fish scale collagen congelation leisure food

A fish scale collagen and snack food technology, which is applied in the field of food processing, can solve the problems of environmental pollution, discarding, waste of resources, etc., and achieve the effects of reducing environmental pollution, easily relieving stress, and eating safely and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The process of making fish -like collagen is:

[0039] Fish scales → cleaning → drying → decontamination → extraction → filtration → removing fishy → decoloring → filtration → freezing drying → collagen;

[0040] (1) Desequent: Take 7G fish scales in a citrate solution with a mass score of 200ml of 5%of the citric acid solution for 30 minutes and wash it with distilled water;

[0041] (2) Extraction: The citric acid solution with a citric acid with a mass score of 40%after decapagulative is extracted by 3:10 and the collagen is obtained.

[0042] (3) Take off: Add volume score to 0.5%liquor and 0.5%white vinegar in the collagen extraction solution, and add 1h to a static; add β-cyclic paste with a mass score of 1.0%, buried 40 at 40 ℃ at 40 ℃min,

[0043] (4) True discoloration: Use the activated carbon with a mass score of 2%at 40 ° C for 20 minutes;

[0044] 2. Product production

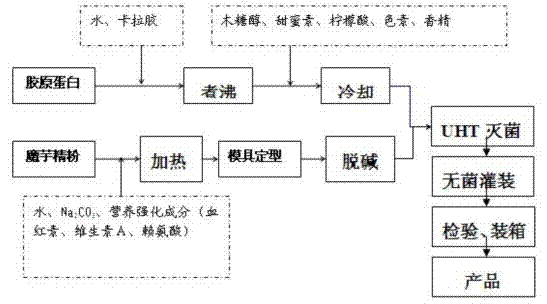

[0045] Product production process flow chart figure 1 The

[0046](1) Fish squamous collage...

Embodiment 2

[0052] The process of making fish -like collagen is:

[0053] Fish scales → cleaning → drying → decontamination → extraction → filtration → removing fishy → decoloring → filtration → freezing drying → collagen;

[0054] (1) Desequent: Take 13g fish scales in a citrate solution with a mass score of 300ml of 300ml of citric acid solution for 60 min, wash with distilled water;

[0055] (2) Extraction: The citric acid solution with a citric acid with a mass score of 60%after decapylment is extracted by 3:10 and the collagen is obtained.

[0056] (3) Take off: Add volume score to 2%liquor and 2%white vinegar in the collagen extraction solution, and then add 3h; then add β-cyclic paste with a mass score of 3.0%.min,

[0057] (4) True discoloration: Use the activated carbon with a mass score of 4%to adsorb 40min at 65 ° C;

[0058] 2. Product production

[0059] Product production process flow chart figure 1 The

[0060] (1) Fish squamous collagen solution: Solk fish scale collagen and K...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com