Device and method for coupling catalyst recovery process with dynamic disc membrane separation process

A disc type, catalyst technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low separation efficiency, high production cost, large circulation volume, etc., and achieve high permeation flux , Small footprint, improved economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

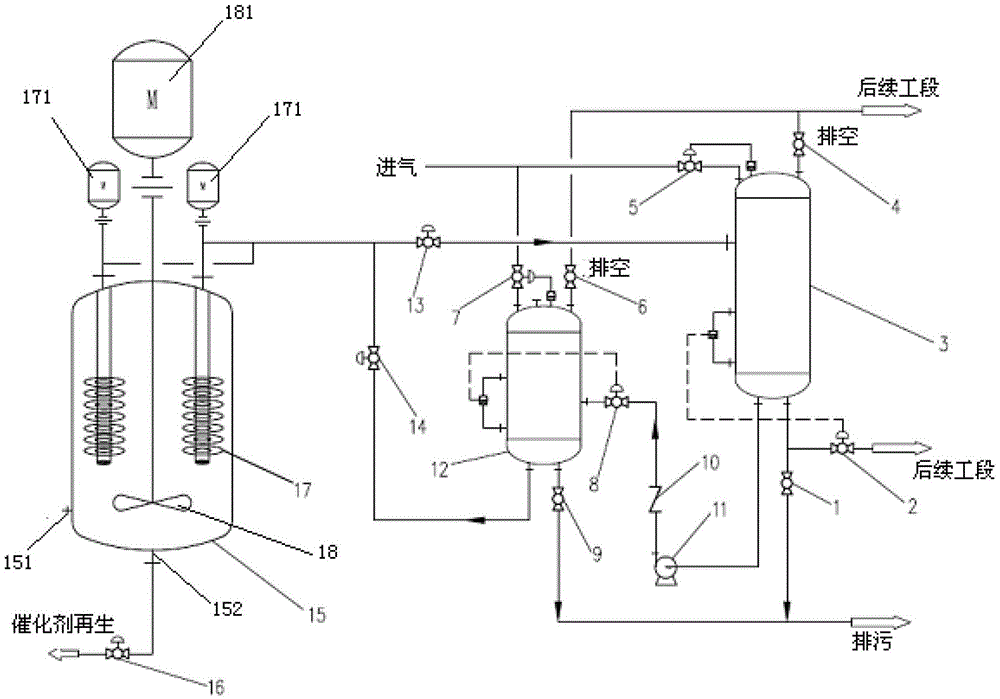

[0036] Embodiment: Catalyst recovery in oximation process in the production of caprolactam

[0037]At present, titanium-silicon molecular sieves are used in China to catalyze the ammoximation of cyclohexanone to prepare cyclohexanone oxime. Tert-butanol, ammonia, and catalyst react in the reaction kettle 15, and the catalyst concentration is 3%. After the reaction is complete, the reaction solution containing the catalyst is separated by a ceramic disc (the main body 17 of the dynamic disc separator in the present invention) , the clear liquid enters the clear liquid tank 3 through the automatic feed control valve 13 of the clear liquid tank, and obtains cyclohexanone oxime through a follow-up process, and then produces caprolactam. The catalyst is retained in the reactor 15 to continue the reaction until it needs to be regenerated, and the catalyst to be regenerated is discharged through the catalyst regeneration outlet 152 for reuse.

[0038] Filtration process:

[0039] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com