Organic anthraquinone dye sensitized and precious metal supported inorganic semiconductor visible-light photocatalyst, and preparation method and application of photocatalyst

An inorganic semiconductor, anthraquinone dye technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as deactivation, and achieve good absorption of visible light performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1). Put 2g of P25 TiO with a particle size of 25 nanometers 2 The carrier is dispersed in 150ml deionized water, and then 3~5.5ml of chloroplatinic acid aqueous solution with a concentration of 0.376g / 100ml (calculated based on the mass of pure platinum metal element, that is, 100ml of chloroplatinic acid aqueous solution contains 0.376g of platinum element) 1.3~2.4ml of propanol, ultrasonic and fully stirred, place in a quartz bottle to obtain a mixed suspension; after the quartz bottle is capped, Ar gas is blown into the quartz bottle to remove oxygen, and then the mixed suspension is irradiated with UV light of a 300W Xe lamp The reaction was stirred for about 12 hours, the product obtained after the reaction was centrifuged, and the solid product obtained after the centrifugal separation was repeatedly washed with deionized water, and dried in a vacuum drying box to fully remove the water, and P25 loaded with platinum nanoparticles was obtained. TiO 2 Carrier

[0041]...

Embodiment 2

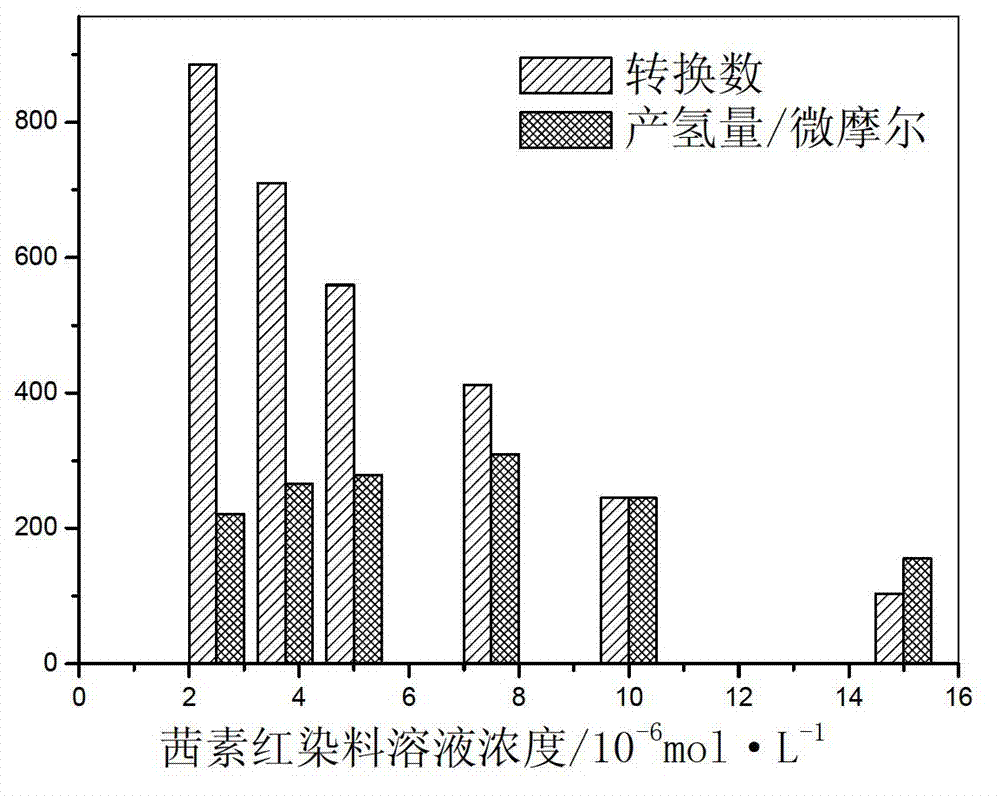

[0054] In this example, by changing the concentration of the dye solution during in-situ adsorption and sensitization of alizarin red dye, the change of the concentration of the sensitizer was studied in the hydrogen production experiment, the hydrogen production rate and the conversion number of the alizarin red sensitizer ( TON) varies with the concentration of the dye solution.

[0055] Prepare different concentrations of Alizarin Red dye solutions according to the method in Example 1, so that the P25 type TiO loaded with platinum nanoparticles 2 The surface of the carrier adsorbs and sensitizes the Alizarin Red dye in situ; only the organic anthraquinone dye solution in the step (2) of preparing the visible light photocatalyst is replaced with a concentration of 2.5×10 -6 mol / L、3.75×10 -6 mol / L、5×10 -6 mol / L、7.5×10 -6 mol / L、10×10 -6 mol / L and 15×10 -6 mol / L Alizarin Red Dye Solution, Alizarin Red Dye-sensitized P25-type TiO loaded with platinum nanoparticles was prepared from t...

Embodiment 3

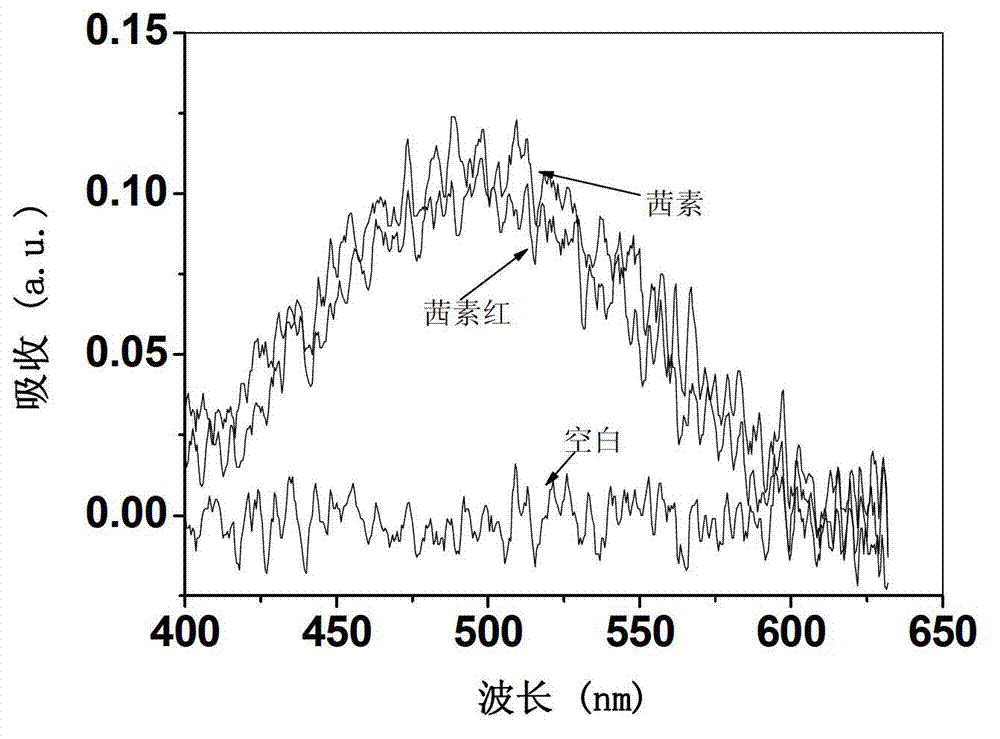

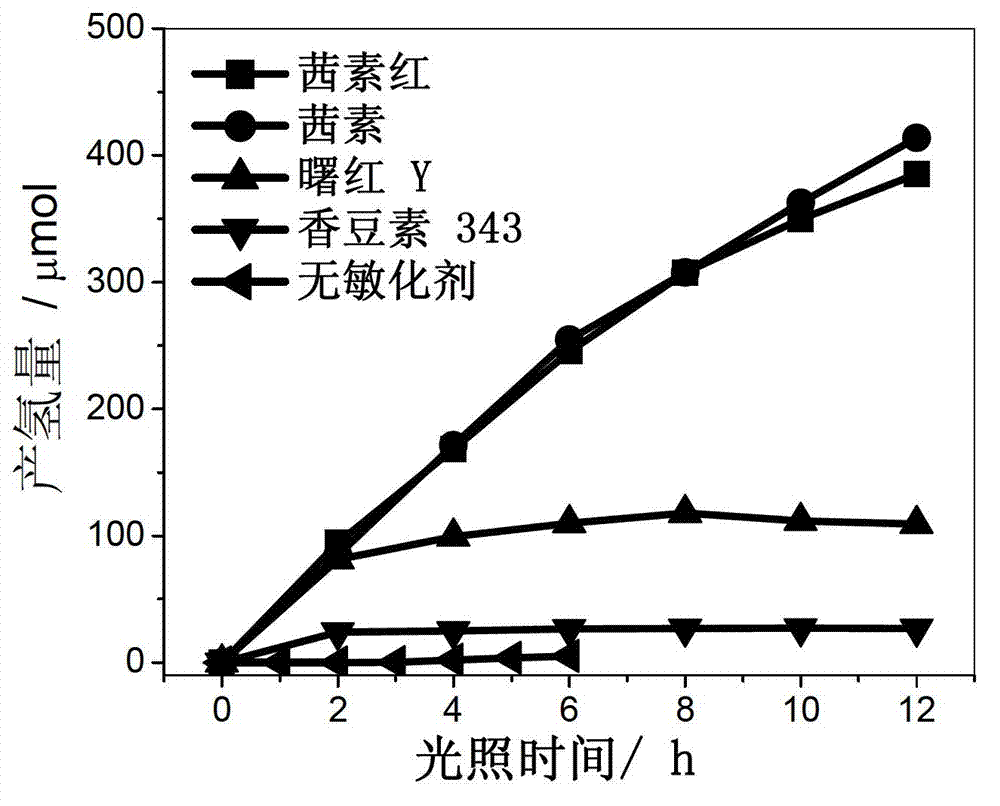

[0059] Prepare the Alizarin Red Dye Solution and Alizarin Dye Solution according to the method in Example 1, so that the P25 type TiO loaded with platinum nanoparticles 2 The surface of the carrier adsorbs and sensitizes Alizarin Red dye and Alizarin dye respectively in situ; among them, only the organic anthraquinone dye solution in step (2) of preparing visible light photocatalyst is replaced with a concentration of 2.5×10 -6 mol / L Alizarin Red Dye Solution and Alizarin Dye Solution, from the above concentration are 2.5×10 -6 Alizarin red dye solution sensitizer and alizarin dye solution sensitizer were prepared with mol / L Alizarin Red dye and Alizarin dye sensitized P25-type TiO with platinum nanoparticles 2 Visible light photocatalyst, in which the supported platinum nanoparticles account for P25 TiO 2 The total mass fraction of the carrier and the platinum nanoparticles is about 0.8%, and the amount of alizarin red dye and alizarin dye adsorbed and sensitized in situ is relati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com