Preparation method for micron spherical silver powder for electronic paste

A micron-scale technology for electronic paste, which is applied in the field of preparation of spherical silver powder for micron-scale electronic paste, can solve the requirements of product purity, particle size, shape and other performance characteristics that are difficult to apply, long preparation cycle, and serious environmental pollution. and other problems, to achieve the effect of narrow particle size distribution, good gloss, and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Prepare 0.02mol / L silver nitrate solution A and 0.02mol / L ascorbic acid solution C with distilled water respectively, and dissolve bovine serum albumin with 5% silver nitrate mass in distilled water to prepare solution B;

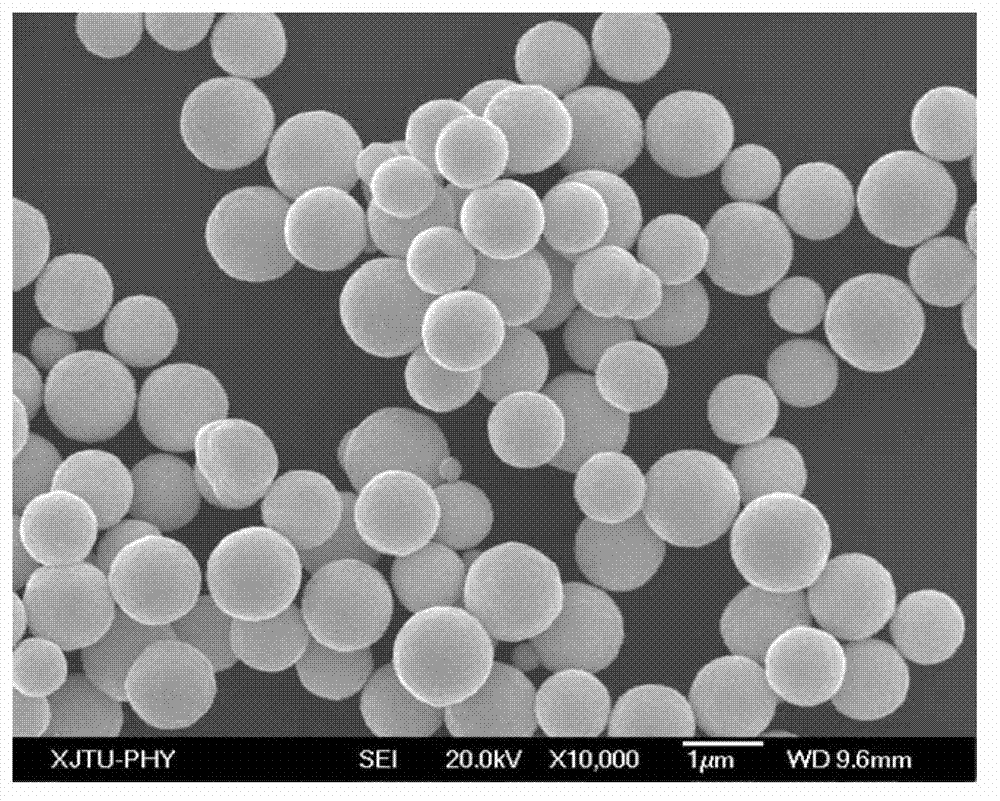

[0028] 2) Pour solution A into solution B at 15°C, then add ammonia water with a mass concentration of 25-28% to adjust the initial pH value to 8, stir well and then press the molar ratio of ascorbic acid: silver nitrate = 1:1 to quickly Add ascorbic acid solution C, react for ten minutes, stop stirring, and finally after ultrasonic dispersion for 6 minutes, stand still, separate, wash with distilled water and absolute ethanol for 1 to 3 times each, and dry at 50°C for 8 hours to obtain the average particle size 0.96μm spherical silver powder, such as figure 1 shown.

Embodiment 2

[0030] 1) Prepare 0.04mol / L silver nitrate solution A and 0.08mol / L ascorbic acid solution C with distilled water respectively, and dissolve bovine serum albumin with 8% silver nitrate mass in distilled water to prepare solution B;

[0031] 2) Pour solution A into solution B at 20°C, then add ammonia water with a mass concentration of 25-28% to adjust the initial pH value to 9, stir well and then press the molar ratio of ascorbic acid:silver nitrate=1.2︰1 to quickly Add ascorbic acid solution C, react for ten minutes, stop stirring, and finally after ultrasonic dispersion for 8 minutes, stand still, separate, wash with distilled water and absolute ethanol for 1 to 3 times each, and dry at 55°C for 6 hours to obtain the average particle size 0.53μm spherical silver powder.

Embodiment 3

[0033] 1) Prepare 0.8 mol / L silver nitrate solution A and 0.8 mol / L ascorbic acid solution C with distilled water respectively, and dissolve bovine serum albumin with 10% silver nitrate mass in distilled water to prepare solution B;

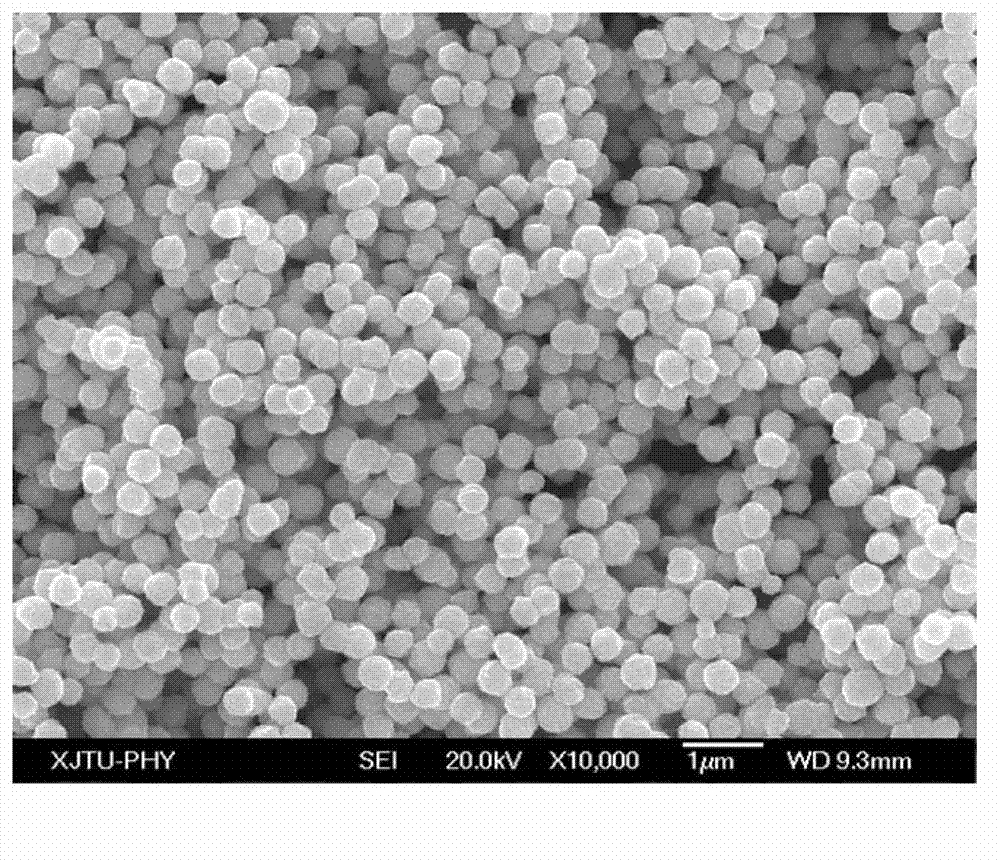

[0034] 2) Pour solution A into solution B at 25°C, then add ammonia water with a mass concentration of 25-28% to adjust the initial pH value to 8.5, stir well and then press the molar ratio of ascorbic acid:silver nitrate=1.4︰1 to quickly Add ascorbic acid solution C, react for ten minutes, stop stirring, and finally after ultrasonic dispersion for 10 minutes, stand still, separate, wash with distilled water and absolute ethanol for 1 to 3 times each, and dry at 52°C for 7 hours to obtain the average particle size 0.34μm spherical silver powder, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com