Preparation method for biosensor based on graphene/carbon nano-tube

A technology of biosensors and carbon nanotubes, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of carcinogenicity, environmental pollution, and mutagenicity in animals, improve the load rate, make the preparation method simple and easy, and improve electron transfer speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

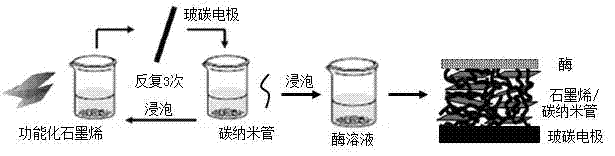

[0027] 1) Preparation of functionalized graphene GO-PEG: 200 mg of graphite oxide GO was added to 10 ml of DMF, and ultrasonically treated at 70 kHz for 3 hours to obtain a stable GO / DMF dispersion. 40ml SOCl 2 Add it to the dispersion liquid, reflux for 48 hours at a temperature of 80°C, and distill off excess SOCl 2 . Then 2g of PEG4000 was added to the reactant, and the reaction was refluxed at 120°C for 96 hours, washed with ethanol and water until neutral, and dried in vacuum at 60°C to obtain functionalized graphene GO-PEG.

[0028] (2) Mix 0.5g of carbon nanotubes and 100mL of strong oxidizing acid, treat it under 120kHz ultrasonic wave for 5 hours, then heat to 120°C, stir and reflux for 72 hours, dilute and wash with deionized water and filter with microporous membrane , until the filtrate is neutral, and vacuum-dried at 60° C. for 48 hours to obtain carboxylated carbon nanotubes.

[0029] (3) Preparation of biosensors:

[0030] a. Pretreatment of glassy carbon e...

Embodiment 2

[0034] 1) Preparation of functionalized graphene GO-PEG: 200 mg of graphite oxide GO was added to 10 ml of DMF, and ultrasonically treated at 70 kHz for 3 hours to obtain a stable GO / DMF dispersion. 40ml SOCl 2 Add it to the dispersion liquid, reflux for 48 hours at a temperature of 80°C, and distill off excess SOCl 2 . Then 2g of PEG600 was added to the reactant, and the reaction was refluxed at 120°C for 72 hours, washed with ethanol and water until neutral, and dried in vacuum at 60°C to obtain functionalized graphene GO-PEG.

[0035] (2) Mix 0.5g of carbon nanotubes and 100mL of strong oxidizing acid, treat it under 120kHz ultrasonic wave for 5 hours, then heat to 120°C, stir and reflux for 72 hours, dilute and wash with deionized water and filter with microporous membrane , until the filtrate is neutral, and vacuum-dried at 60° C. for 48 hours to obtain carboxylated carbon nanotubes.

[0036] (3) Preparation of biosensors:

[0037] a. Pretreatment of glassy carbon el...

Embodiment 3

[0040] 1) Preparation of functionalized graphene GO-PEG: 200 mg of graphite oxide GO was added to 10 ml of DMF, and ultrasonically treated at 70 kHz for 3 hours to obtain a stable GO / DMF dispersion. 40ml SOCl 2 Add it to the dispersion liquid, reflux for 48 hours at a temperature of 80°C, and distill off excess SOCl 2 . Then 2g of PEG1000 was added to the reactant, and the reaction was refluxed at 120°C for 72 hours, washed with ethanol and water until neutral, and dried in vacuum at 60°C to obtain functionalized graphene GO-PEG.

[0041] (2) Mix 0.5g of carbon nanotubes and 100mL of strong oxidizing acid, treat it under 120kHz ultrasonic wave for 5 hours, then heat to 120°C, stir and reflux for 72 hours, dilute and wash with deionized water and filter with microporous membrane , until the filtrate is neutral, and vacuum-dried at 60° C. for 48 hours to obtain carboxylated carbon nanotubes.

[0042] (3) Preparation of biosensors:

[0043] a. Pretreatment of glassy carbon e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com