Nutritional rice type particles for improving intestinal canal and processing method thereof

A processing method and technology of nutritious rice, applied in the field of food processing, to achieve the effects of regulating micro-ecological health, preventing constipation and promoting proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The composition and proportion of the present invention are as follows: 54.0% japonica rice flour, 15.0% fructooligosaccharide, 30.0% dietary fiber and 1.0% monoglyceride.

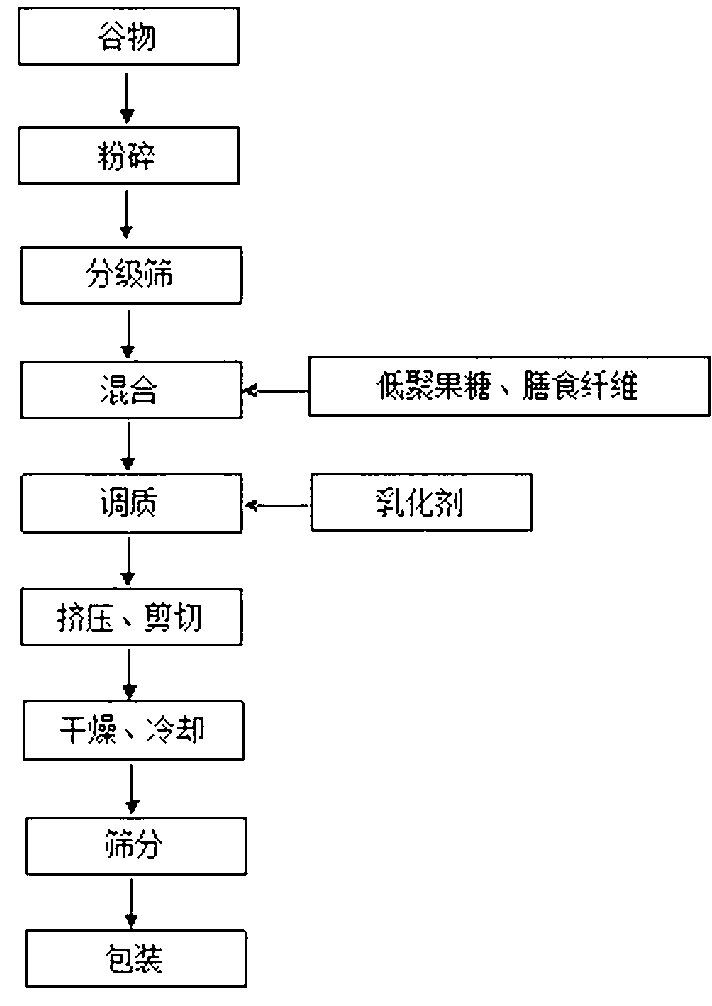

[0033] like figure 1 As shown, firstly, the japonica rice raw material is cleaned of impurities and foreign matter, and after the japonica rice is ground into powder by a high-efficiency grinder, the japonica rice flour is sieved out with an 80-mesh sieve.

[0034] Use the feeding system to accurately weigh 54 kg of japonica rice flour, 15 kg of fructooligosaccharides and 30 kg of dietary fiber, and put them into a mixer for full pre-mixing. The working parameters are: steam speed 25.7 kg / h, water speed 29.3 kg / h , the speed of japonica rice flour is 100 kg / h, the speed of fructooligosaccharides is 15 kg / h, the speed of dietary fiber is 85 kg / h, and the temperature is 97 ℃; accurately add 1.0 kg of monoglyceride until all the raw and auxiliary materials are mixed, then carry out BCHC-preparation Co...

Embodiment 2

[0039] The composition and proportion of the present invention are as follows: 53.75% indica rice flour, 20.0% fructooligosaccharide, 25.0% dietary fiber and 1.25% monoglyceride.

[0040] like figure 1As shown, the indica rice raw material is firstly cleaned of impurities and foreign matter, and after the indica rice is ground into powder by a high-efficiency grinder, the indica rice powder is sieved with an 80-mesh sieve.

[0041] Use the feeding system to accurately weigh 53.75 kg of indica rice flour, 20.0 kg of fructooligosaccharides and 25.0 kg of dietary fiber, and put them into a mixer for full mixing. The working parameters are: steam speed 20.0 kg / h, water speed 20.0 kg / h, The speed of indica rice flour is 95 kg / h, the speed of fructooligosaccharides is 20 kg / h, the speed of dietary fiber is 80 kg / h, and the temperature is 95 ℃; accurately add 1.25 kg of monoglyceride, and after all the raw and auxiliary materials are mixed, carry out BCHC-preconditioning Conditioner...

Embodiment 3

[0046] The composition and proportion of the present invention are as follows: 59.25% corn flour, 25.0% fructooligosaccharide, 15.0% dietary fiber and 0.75% soybean lecithin powder.

[0047] like figure 1 As shown, the corn is firstly cleaned of impurities and foreign matter, and after the corn is ground into powder by a high-efficiency grinder, the corn flour is screened out with an 80-mesh sieve.

[0048] Use the feeding system to accurately weigh 59.25 kg of corn flour, 25.0 kg of fructooligosaccharides and 15.0 kg of dietary fiber, and put them into a mixer to fully mix them. The working parameters are: steam speed 30.0 kg / h, water speed 30.0 kg / h, The corn flour speed is 110 kg / h, the fructooligosaccharide speed is 25 kg / h, the dietary fiber speed is 90 kg / h, and the temperature is 100 ℃; accurately add 0.75 kg of soybean lecithin powder until all the raw and auxiliary materials are mixed, then carry out BCHC-preparation Conditioner conditioning, adding steam and water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com