Carbon-coated attapulgite clay composite material and its preparation method

The technology of attapulgite clay and composite material is applied in the field of nanomaterials, which can solve the problems of small adsorption capacity and incomplete adsorption, and achieve the effects of simple preparation method, low price and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]The present invention also provides a method for preparing a carbon-coated attapulgite clay composite material, comprising the following steps:

[0044] The attapulgite clay and glucose were mixed in water, and the carbon-coated attapulgite clay composite material was obtained after carbonization reaction.

[0045] The invention uses attapulgite clay as a template and glucose as a raw material to obtain a carbon-coated attapulgite clay composite material. The raw material is cheap and has a wide range of sources, the preparation method is simple, and there is no pollution to the environment. The obtained carbon-coated attapulgite clay composite material The clay composite material has good adsorption capacity and has a remarkable effect when used to adsorb and remove heavy metal ions in water.

[0046] The invention firstly mixes the attapulgite clay and glucose in water, and after uniform stirring, the glucose undergoes carbonization reaction using the attapulgite clay ...

Embodiment 1

[0055] At room temperature, 0.5g of attapulgite clay and 1.5g of glucose were dissolved in 38mL of water, and after stirring evenly, the resulting mixed solution was transferred to a polytetrafluoroethylene reactor; the reactor was heated to 160°C and reacted at constant temperature for 48h; then Cool the reactor to room temperature, filter the obtained reaction product with a filter membrane with a pore size of 220 nm, wash the filtered product with water and ethanol respectively, and dry it in an oven at 60°C for 24 hours to obtain a carbon-coated attapulgite clay composite material.

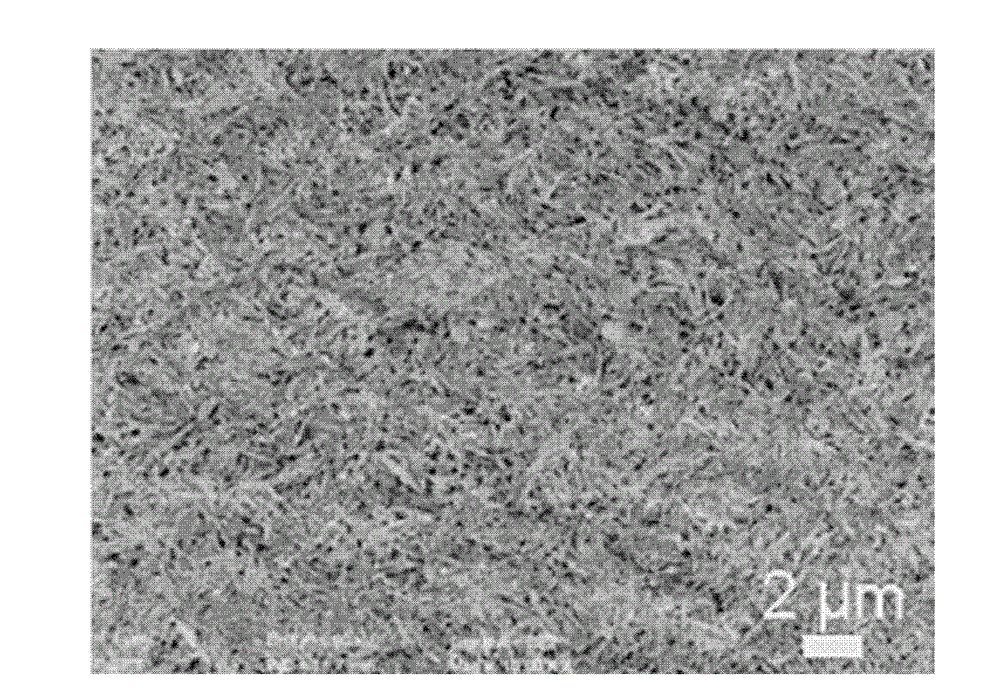

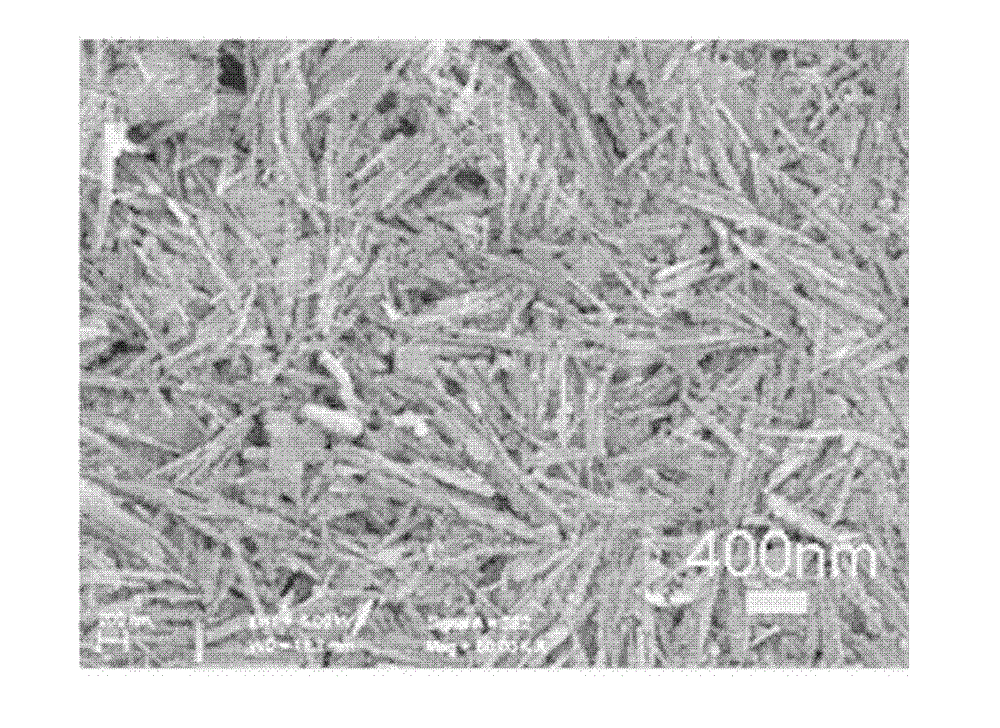

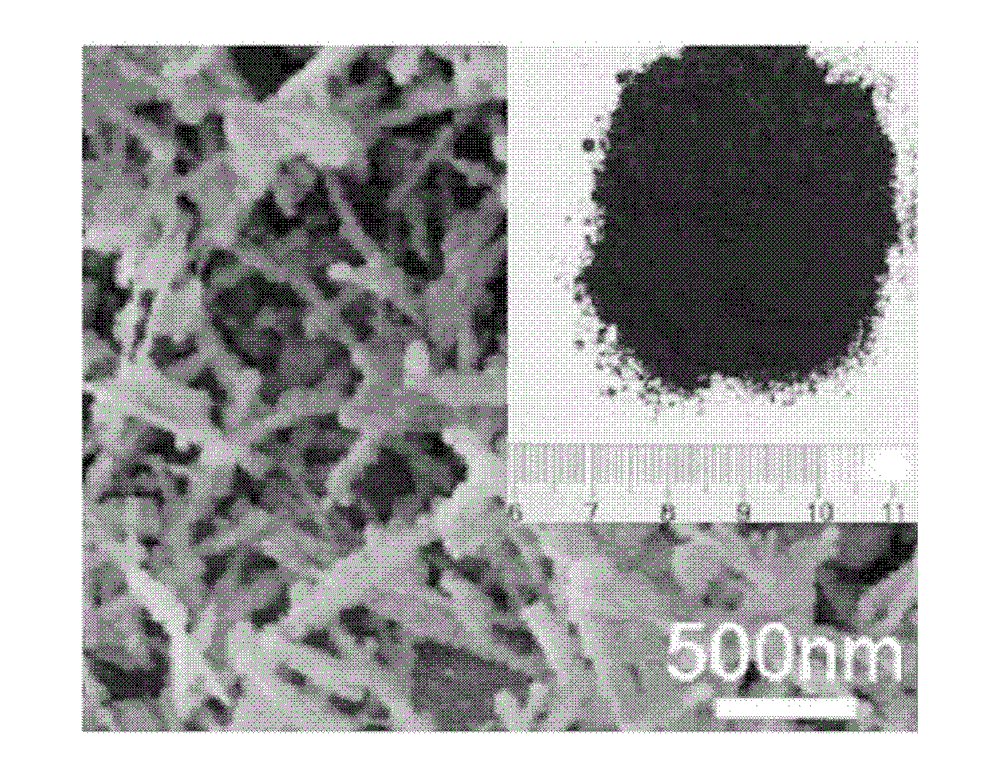

[0056] The carbon-coated attapulgite clay composite was observed with a field emission scanning electron microscope, and the results can be found in figure 1 , figure 2 and image 3 , figure 1 The low-magnification scanning electron micrograph of the carbon-coated attapulgite clay composite material provided by Example 1 of the present invention, figure 2 A high-magnification scanning ele...

Embodiment 2

[0060] At room temperature, dissolve 0.5g of attapulgite clay and 4.0g of glucose in 38mL of water, stir well and transfer the resulting mixed solution into a polytetrafluoroethylene reactor; raise the temperature of the reactor to 160°C, and react at a constant temperature for 48h; then Cool the reactor to room temperature, filter the obtained reaction product with a filter membrane with a pore size of 220 nm, wash the filtered product with water and ethanol respectively, and dry it in an oven at 60°C for 24 hours to obtain a carbon-coated attapulgite clay composite material.

[0061] The carbon-coated attapulgite clay composite was observed with a field emission scanning electron microscope, and the results can be found in Figure 7 and Figure 8 , Figure 7 The low-magnification scanning electron micrograph of the carbon-coated attapulgite clay composite material provided by Example 2 of the present invention, Figure 8 A high-magnification scanning electron micrograph of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com