Manufacture method of reversible bonding micro-fluidic chip with high strength

A microfluidic chip, high-strength technology, applied in the field of microfluidic systems and lab-on-a-chip, can solve the problems of low bonding strength, low yield of sandwich microfluidic chips, and limitations of microfluidic design and application, etc. Achieve the effect of avoiding deformation and collapse, expanding the scope of application, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The substantive features and remarkable progress of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] The specific process of processing a high-strength reversible bonding microfluidic chip proposed by the present invention is as follows:

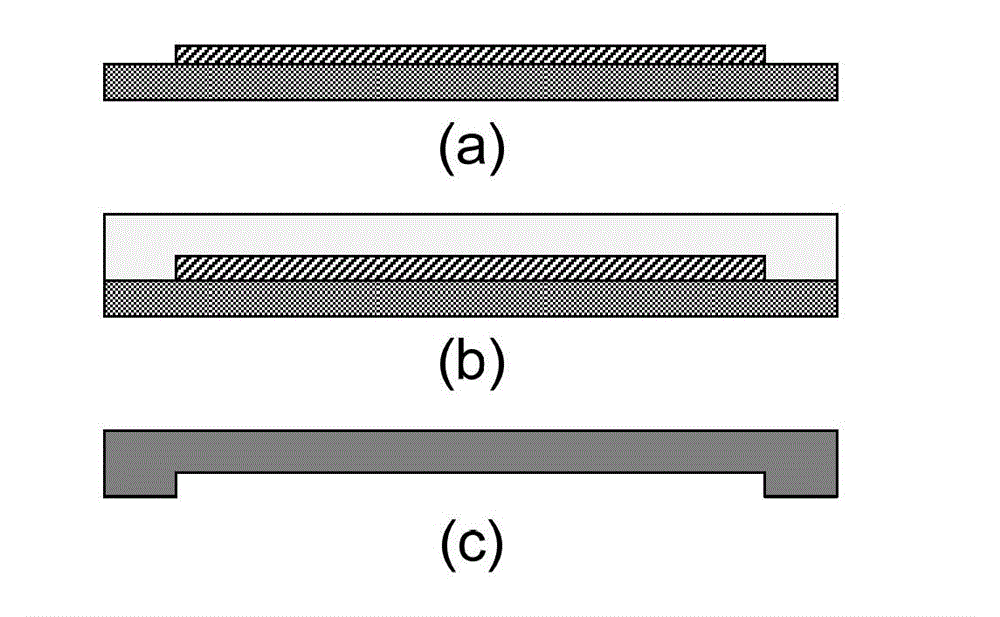

[0020] 1. Using SU-8 negative photoresist, make a master mold on a silicon wafer through the steps of coating, soft baking, exposure, post-baking, development, and hard baking (such as figure 1 a); Then pour the PDMS prepolymer and curing agent mixture (10:1, w / w) on the master mold (such as figure 1 b), thermally cured (~85°C, 1hr), and peeled off to make a PDMS reverse mold (eg figure 1 c).

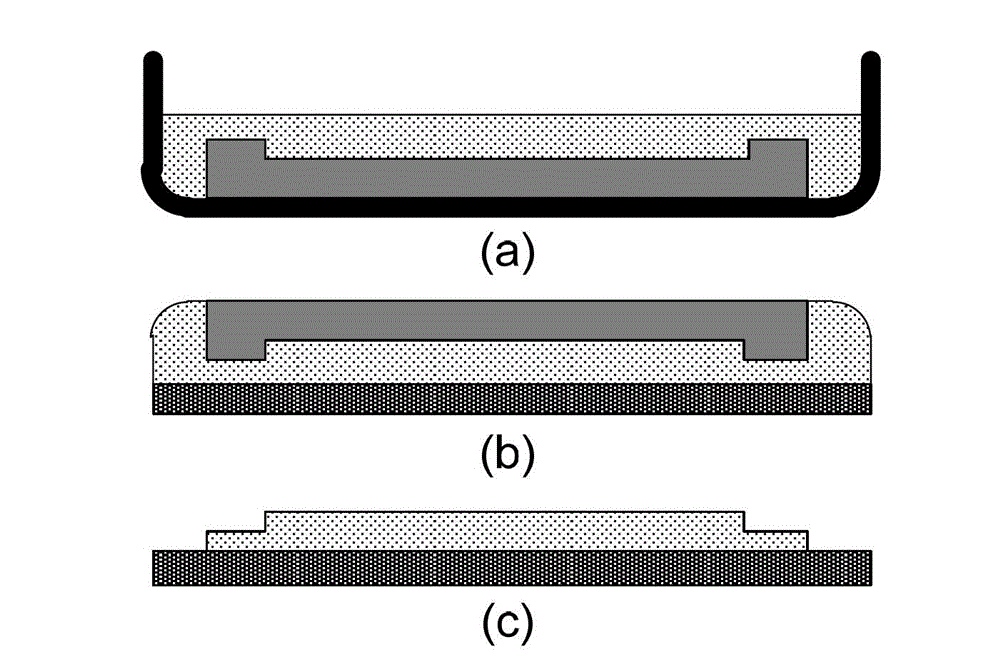

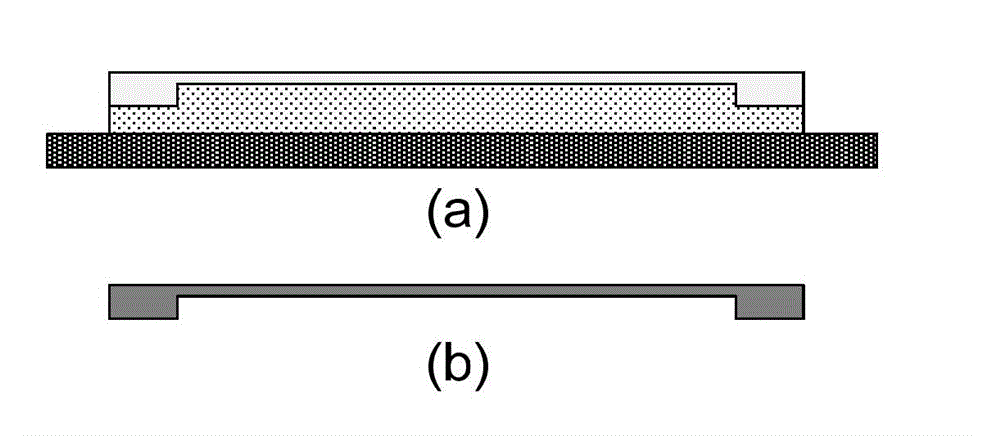

[0021] 2. Attach the PDMS reverse mold structure to the bottom of the petri dish outwards, and then pour the agarose solution (such as figure 2 a) After the agarose solution is cooled and solidified, take out the reversed PDMS mold and agarose and place it upside d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com