Synthesis method for d, l-menthol and stereoisomers thereof

A technology of stereoisomers and synthesis methods, applied in the field of d, can solve the problems of non-reusable hydrocarbon by-products, high equipment requirements, and harsh operating conditions, and achieve mild operating conditions, low equipment requirements, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

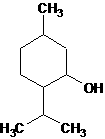

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of composite Raney nickel catalyst: 625g mass concentration 20% sodium hydroxide aqueous solution, under stirring and ice-water bath cooling, add the aluminum-nickel alloy of 60-100 purpose to contain iron, molybdenum, chromium in batches in fume hood Powder 100g, control the temperature below 25°C and continue stirring for 30 minutes; stop stirring and let the reaction solution rise to room temperature; Overflow; add distilled water continuously during the heating process, so that the volume of the reaction solution is basically constant until the generation of hydrogen slows down again;

[0028] Stand still, until the nickel powder sinks, pour out the supernatant; wash with equal volumes of distilled water and 5% sodium hydroxide aqueous solution with a mass concentration, and pour out the supernatant; repeat the washing with water several times until the aqueous solution is neutral; wherein, In addition to nickel, the catalyst also conta...

Embodiment 2

[0029] Example 2: 3L autoclave, 1500g thymol, 42.9g of the catalyst of Example 1, operate according to the usual hydrogenation procedure: hydrogen pressure 0.1MPa, heated to a temperature of 200°C and stirred for 8 hours, cooled the material, and suction filtered , the product composition obtained is as follows (GC): d, l-neomenthol 27.82%; d, l-neomenthol 1.63%; d, l-menthol 57.77%; d, l-isomenthol 12.18%; d, l-menthone 0.16%; hydrocarbons 0.03%; by fractional distillation under reduced pressure, d, l-menthol, d, l-isomenthol, d, l-neomenthol were obtained respectively; the product yield is the theoretical yield 99.5% of.

Embodiment 3

[0030] Embodiment 3: operate with embodiment 2; Wherein, hydrogen pressure 0.5MPa, temperature 180 ℃ under stirring reaction 10 hours; Wherein, starting material is composed of: thymol 70%, d, l-neomenthol 20.82%, d, l-neeomenthol 5.63%, d, l-menthol 2.77%, d, l-menthone 0.6%, hydrocarbon 0.18%; the composition of the product obtained after the reaction is as follows: d, l-neeomenthol 26.20% , d, l-neo-menthol 1.83%, d, l-menthol 58.79%, d, l-isomenthol 12.5%, d, l-menthone 0.26%, hydrocarbon 0.22%; menthol mixed product The yield is 99.3% of the theoretical yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com