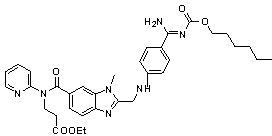

Preparation method of 3-(2-pyridineamino)ethyl propionate

A kind of technology of ethyl propionate and pyridyl amino, applied in the field of preparation of ethyl 3-propionate, can solve the problems of long synthesis steps, long reaction time and high production cost, and achieves low production cost, short reaction time and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

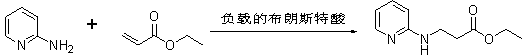

[0028] A kind of preparation method of 3-(2-pyridylamino) ethyl propionate, the steps are as follows:

[0029] Add 2-aminopyridine (0.47g, 5mmol) and ethyl acrylate (1.0g, 10mmol) to four 25mL round bottom flasks or 15mL sealed tubes, respectively, and then add perchloric acid (0.5 g, 0.5mmol), 200-300 mesh silica gel loaded perchloric acid (0.5g, 0.5mmol), 300-400 mesh silica gel loaded perchloric acid (0.5g, 0.5mmol), silica gel H loaded perchloric acid ( 0.5g, 0.5mmol) as the catalyst, under the condition of ethanol (2mL) as the organic solvent, the reaction temperature was controlled at 100°C for 24h, the reaction mother liquor obtained after the reaction was separated by a centrifuge, the supernatant was taken, and the supernatant The supernatant liquid is concentrated at a temperature of 40-45°C and a pressure of 0.09-0.1 MPa under reduced pressure. The concentrated liquid is passed through a silica gel column or an aluminum oxide column with a ratio of petroleum ether:e...

Embodiment 2

[0032] A kind of preparation method of 3-(2-pyridylamino) ethyl propionate, the steps are as follows:

[0033] Add 2-aminopyridine (0.47g, 5mmol) and ethyl acrylate (1.0g, 10mmol) into a 25mL round bottom flask or a 15mL sealed tube, add perchloric acid (0.5g 0.5mmol) loaded on 200-300 mesh silica gel Catalyst, ethanol (2mL) as solvent, control the temperature at 100°C for 24 hours, separate the reaction mother liquor obtained after the reaction with a centrifuge, take the supernatant, control the temperature of the supernatant at 40-45°C, and the pressure at 0.09- Concentrate under reduced pressure at 0.1MPa, and the concentrated solution is subjected to column chromatography with a silica gel column or an aluminum oxide column and an eluent with a ratio of petroleum ether:ethyl acetate of 8:1 to 5:1, and the collected 5:1 When the eluent, the white solid product obtained by spinning is 3-(2-pyridylamino) ethyl propionate, and the productive rate is 65%;

[0034] The white s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com