Aliphatic polyester/calcium carbonate composite material and its preparation method

A technology of aliphatic polyester and composite materials, which is applied in the field of aliphatic polyester/calcium carbonate composite materials and its preparation, and can solve the problems of accelerated degradation rate of aliphatic polyester, aseptic inflammation at the implant site, and weak cell adsorption capacity To avoid aseptic inflammatory reactions, improve hydrophilicity and biocompatibility, and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

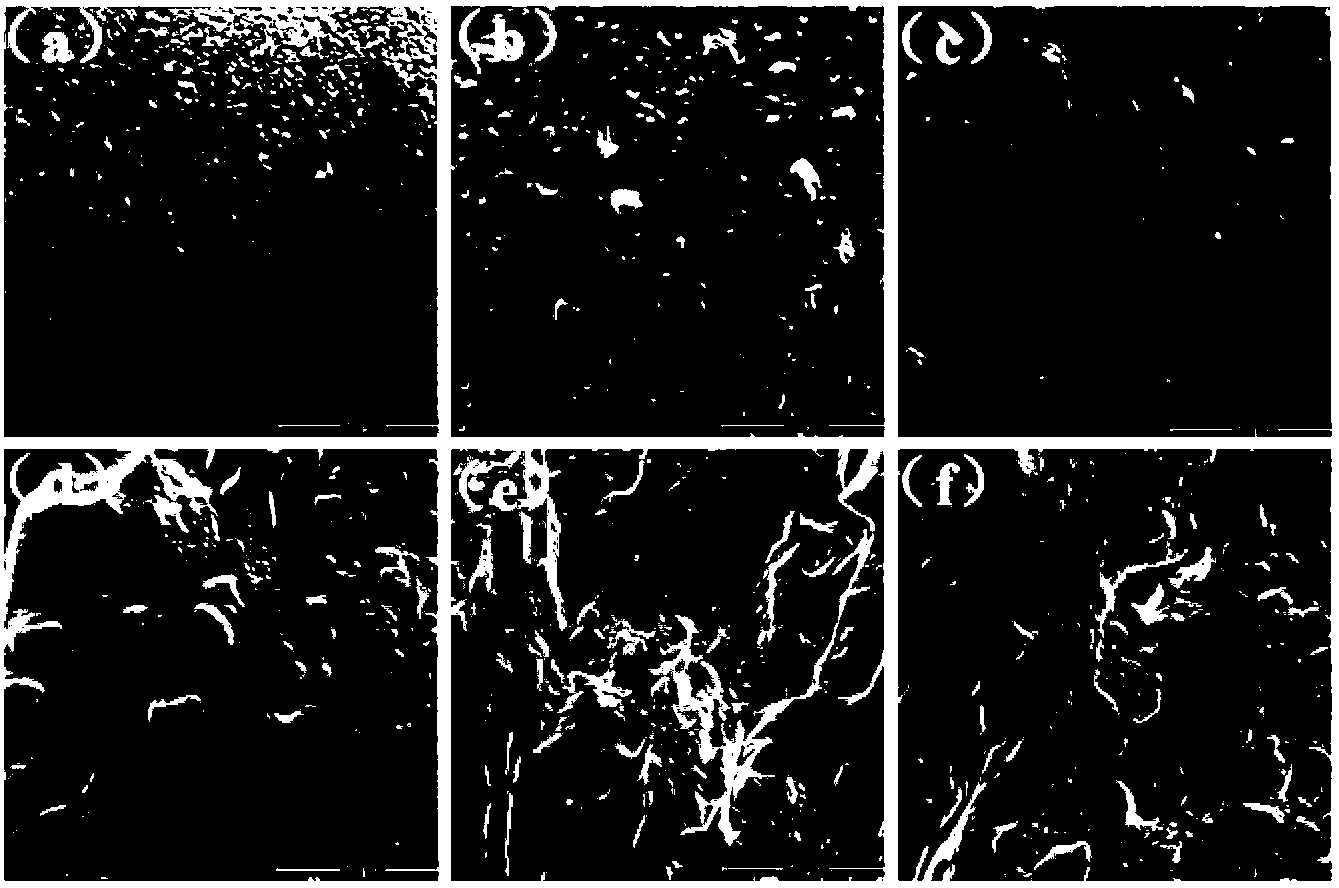

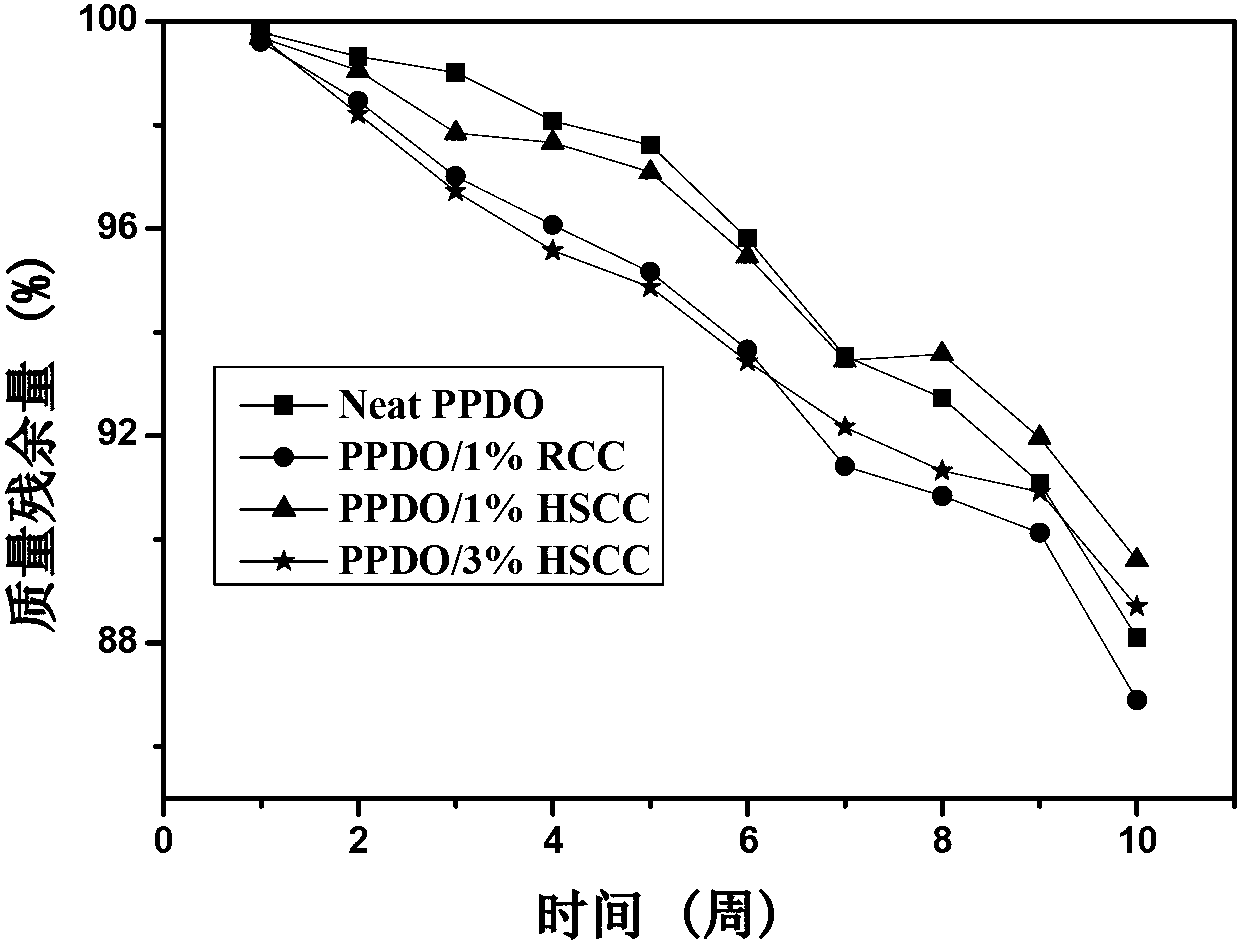

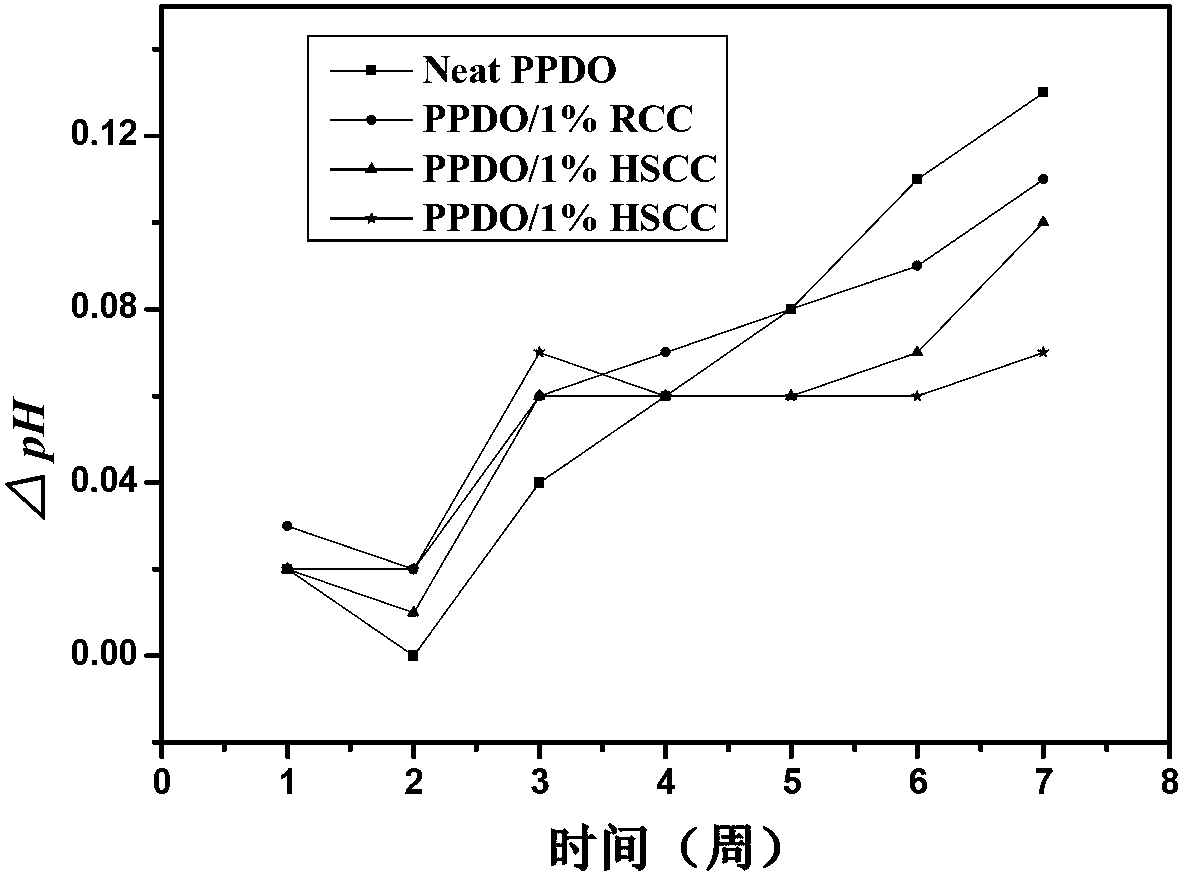

Image

Examples

Embodiment 1

[0037] Under the protection of an inert gas, add 100 parts of ε-CL monomer to 0.3 parts of surface-modified flaky calcium carbonate, ultrasonically disperse at 90 °C for 0.5 h, and then add the mono A stannous octoate catalyst with a volume molar ratio of 0.0005, reacted for 24 hours, cooled, pulverized, and dried.

Embodiment 2

[0039] Under the protection of an inert gas, add 100 parts of ε-CL monomer to 0.6 parts of surface-modified rod-shaped calcium carbonate, ultrasonically disperse at 40°C for 1 hour, and then add the mole of monomer at 80°C while stirring For the stannous octoate catalyst with a ratio of 0.0002, cool, pulverize and dry after reacting for 48 hours.

Embodiment 3

[0041] Under the protection of inert gas, add 100 parts of ε-CL monomer to 2 parts of surface-modified cocoon-like calcium carbonate (PCC), ultrasonically disperse at 80°C for 3h, and then add With the stannous octoate catalyst with a monomer molar ratio of 0.0005, react for 24 hours, cool, pulverize, and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com