Method for preparing high-performance irradiation cross-linking ultrahigh polyethylene extrusion plate

A polyethylene, high-performance technology, applied in the field of preparation of high-performance radiation cross-linked melt-extruded sheets, can solve problems such as damage to inherent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

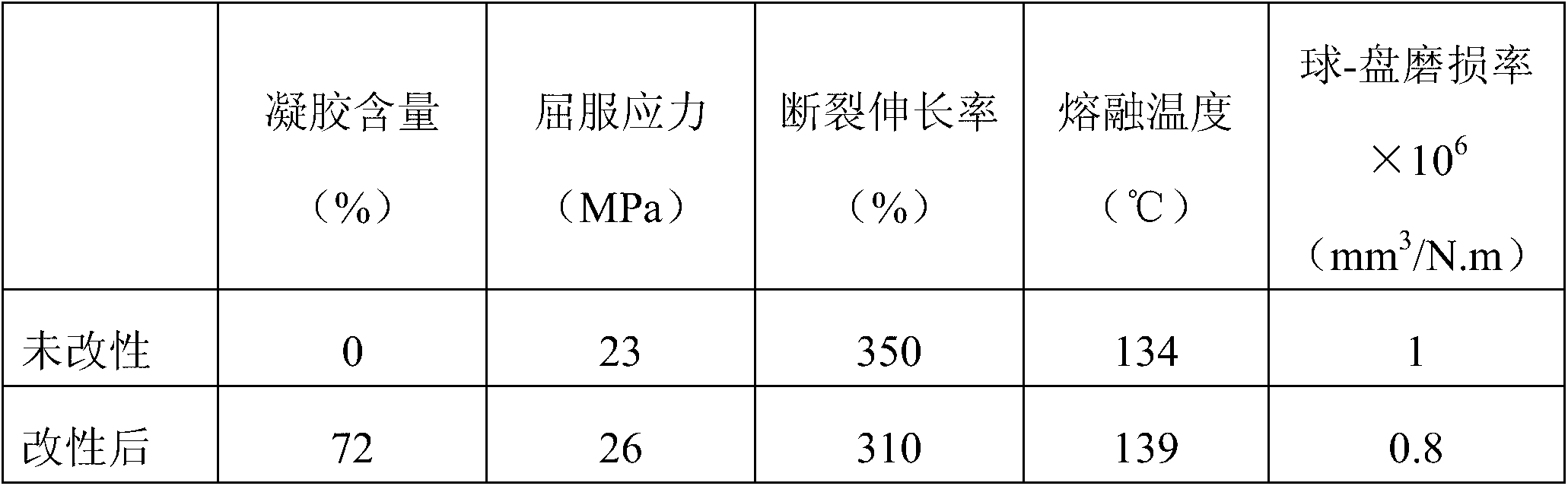

Embodiment 1

[0020] The radiation crosslinked ultra-high molecular weight polyethylene extruded sheet according to the present invention comprises the following steps: using ultra-high molecular weight polyethylene powder with a molecular weight of about 2.5 million as a raw material, and adding 1 wt% of nucleating agent 1,3 -2,4-Dibenzylidene sorbitol, 3wt% polyfunctional sensitizer trimethylolpropane trimethacrylate (TMPTMA), 3wt% polyethylene wax and 1wt% antioxidant 3,4,5-tri Propyl hydroxybenzoate (PG), after being fully mixed, is sent into the extruder, and after conveying, compacting and heating in sequence, it is extruded from the extruder. During the heating process, the temperature and pressure of the raw materials are controlled, and the thickness of the extruded sheet is 10mm. The obtained samples were exposed to air with 60 Co-γ-ray irradiation, the irradiation dose is 40kGy, and the dose rate is 2Gy / s. The irradiated samples were annealed in a vacuum oven at 120°C for 5 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com