Friction material composition for high-performance brake pad

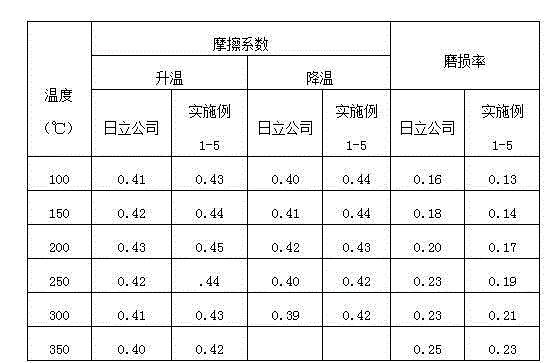

A friction material and composition technology, applied in the field of automobile brake pads, can solve the problems of low thermal decay resistance, high wear rate of brake pads, unstable braking at high temperature, etc., and achieve good thermal degradation resistance, high temperature braking Stable performance and good braking performance

Active Publication Date: 2013-04-24

摩擦一号制动科技(仙桃)有限公司

View PDF7 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a friction material composition for a high-performance brake pad, which is prepared from the following components in percentage by weight: 10-15% of ceramic fiber, 6-8% of aramid fiber pulp, 8-10% of copper powder, 3-5% of wollastonite fiber, 1.2-2.5% of flaky potassium titanate, 6-8% of cellulose fiber, 5-8% of zirconium silicate, 8-10% of vermiculite powder, 1-3% of magnesium hydroxide, 1-3% of aluminum hydroxide, 0.8-1.5% of gas-phase silicon dioxide, 6-10% of barite, 6-8% of titanium white, 5-7% of stannic sulfide, 4-5% of calcined petroleum coke, 6-8% of expanded graphite, 1-2% of nitrile-butadiene rubber and 6-10% of phenolic resin. The brake pad produced according to the formula has favorable strength and excellent wear resistance, and the integral friction factor of the brake pad is enhanced, so that the entire car has better braking performance in the high-speed traveling process and still has favorable heat face resistance after continuous braking; and the brake pad has the advantages of stable high-temperature braking performance and long service life.

Description

technical field [0001] The invention relates to an automobile brake pad, in particular to a friction material composition for a high-performance brake pad. Background technique [0002] Earlier car brake pads were asbestos-type brake pads, but it is now found that asbestos has been confirmed by the medical profession to be a carcinogen. Every time you brake, the brake pads will emit millions of asbestos fibers into the air, and the needle-like fibers can easily enter the lungs and stay there, causing irritation, which can eventually lead to the occurrence of lung cancer, but in addition to endangering health In addition to other factors, there is another important problem in asbestos brake pads. Because asbestos is heat-insulating, its thermal conductivity is particularly poor. After repeated use of the brakes, the heat will accumulate in the brake pads. After the brake pads become hot, their braking performance will change, and the same friction and braking force will be p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K3/14F16D69/02C08L61/06C08L9/02C08K13/04

Inventor 张泽伟

Owner 摩擦一号制动科技(仙桃)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com