Hydrotreating method of heavy oil

A technology for hydrotreating and oil products, which is applied in the fields of hydrotreating process, hydrocarbon oil, petroleum industry, etc. It can solve the problems of hot spots in reactors, easy deactivation of hydrotreating catalysts, and operation cycle of hydrotreating reaction devices. Short and other problems, to achieve the effect of increasing the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the macroporous hydrotreating catalyst (CAT-A) may include: mixing macroporous pseudo-boehmite dry rubber powder with polyvinyl alcohol, adding corn oil and aqueous solution for kneading, and mixing the obtained plastic body Carriers are obtained after shaping, drying and calcining. The catalyst can be prepared by loading the active metal components on the carrier by means of saturated impregnation. The macroporous pseudoboehmite dry rubber powder is commercially available.

[0033] The method of the present invention can adopt reactors of different structures, preferably a fixed-bed reactor.

[0034] In the present invention, there is no special limitation on the flow direction of raw materials in the hydrotreating zone, and each hydrogenation reactor can be either an upflow reactor or a downflow reactor.

[0035] According to the present invention, the hydrotreating reaction conditions may be conventional hydrotreating reaction conditions i...

Embodiment 1

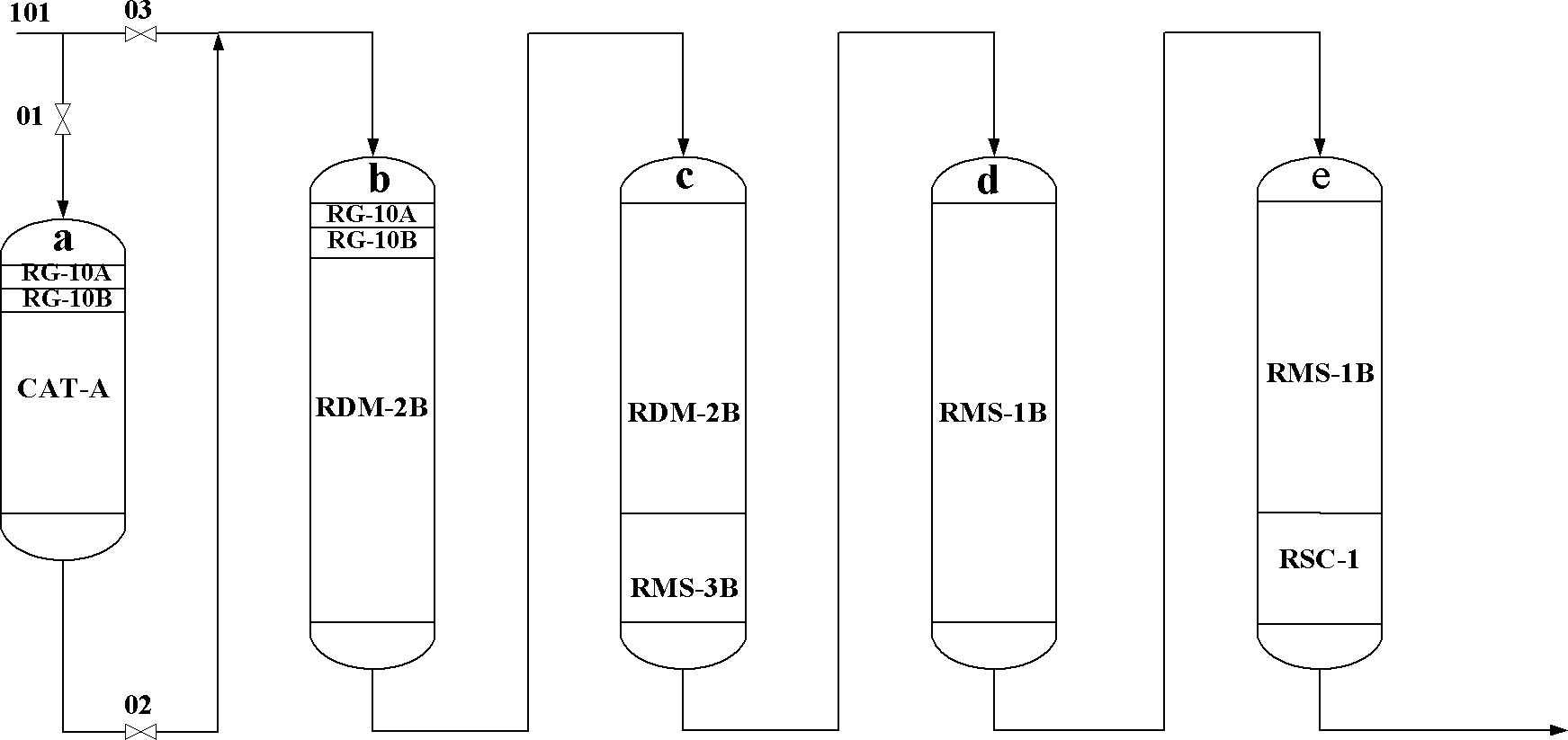

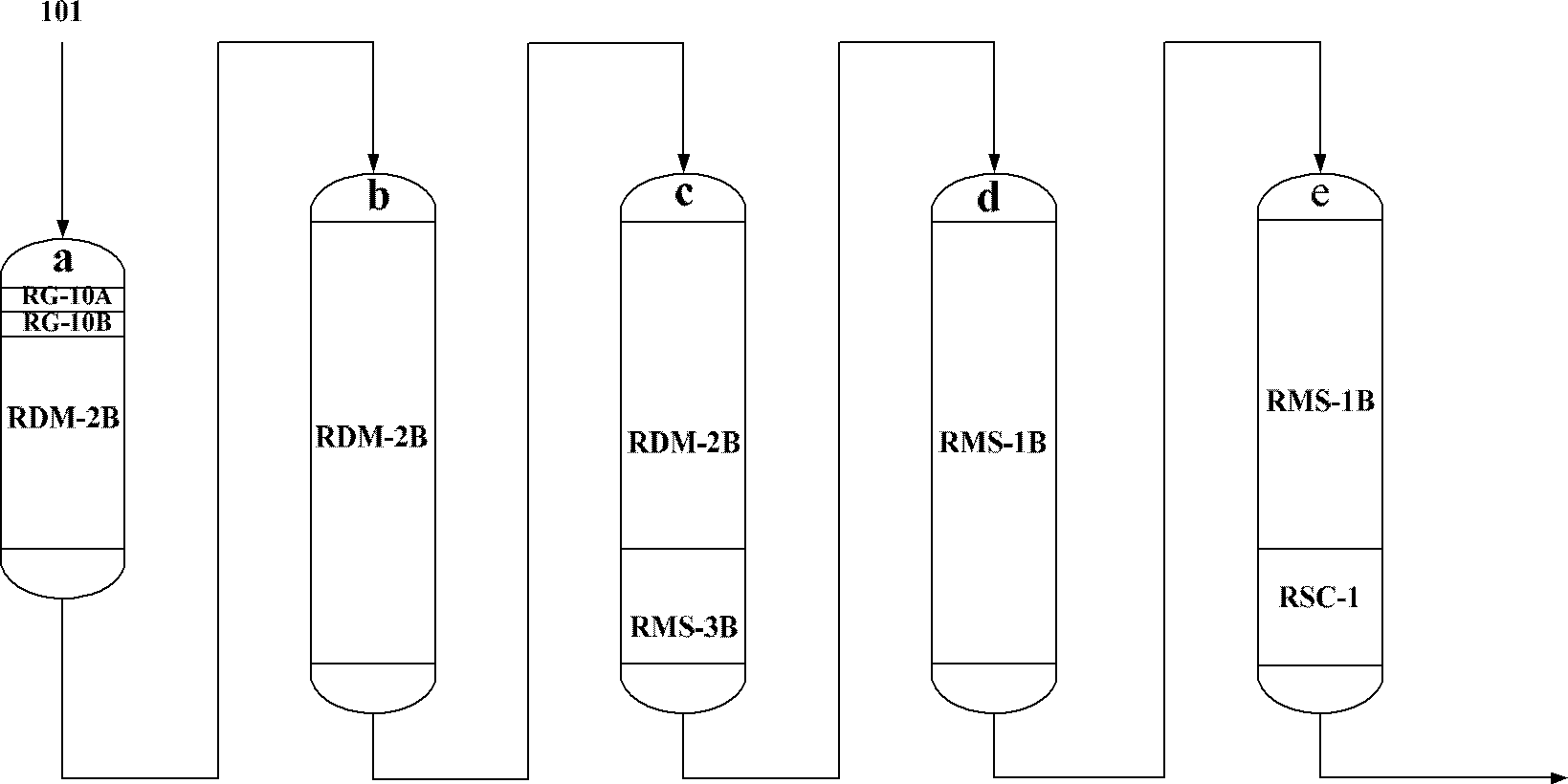

[0059] use figure 1 With the equipment and process flow shown, valve 01 and valve 02 are opened, so that the residue raw material M with high asphaltene content (the main properties are listed in Table 1) and hydrogen enter reactor a, and then enter reactor b, c, and d in sequence and e reactor for hydrotreating, wherein, the catalysts in a reactor are: RG-10A, RG-10B and CAT-A-1 from top to bottom, and the ratio of the loading volume of each catalyst is 10:10:80 ;Hydroprocessing conditions include: reaction pressure 14.7MPa, hydrogen-to-oil volume ratio 600, liquid hourly volume space velocity 0.216h -1 , the reaction temperature of reactor a is 395°C, and the reaction temperature of reactors b, c, d and e is 385°C.

[0060] In the initial stage of stable operation, the properties of the product P1-1 obtained by hydrotreating residual oil include: a sulfur content of 0.30% by weight, a nitrogen content of 0.17% by weight, a residual carbon value of 5.5% by weight, and a heav...

Embodiment 2

[0070] use figure 1 With the equipment and process flow shown, valve 01 and valve 02 are opened, so that the residue raw material M with high asphaltene content and hydrogen enter reactor a, and then enter reactor b, c, d and e in sequence for hydrogenation, Hydrotreating conditions include: reaction pressure 13.2MPa, hydrogen to oil volume ratio 1500, liquid hourly volume space velocity 0.142h -1 , the reaction temperature of reactor a is 400°C, and the reaction temperature of reactors b, c, d and e is 360°C.

[0071] Wherein, according to the type and the volume of the catalyst loaded in the reactor a, b, c, d and e in embodiment 1, each reactor of the present embodiment is packed, and the difference is that the catalyst in the reactor a is from top to bottom: : RG-10A, RG-10B and CAT-A-2, the ratio of each catalyst loading volume is 15:15:70.

[0072] At the initial stage of stable operation, the properties of the product P2-1 obtained after the hydrotreating of residual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com