Cellucotton pad and preparation process thereof

A preparation process and cotton pad technology, applied in the field of fiber cotton pads, can solve the problems of easy layer separation and shedding, easy breeding of bacterial diseases and insect pests, etc., and achieve the effects of saving resources, wide selection of raw materials, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

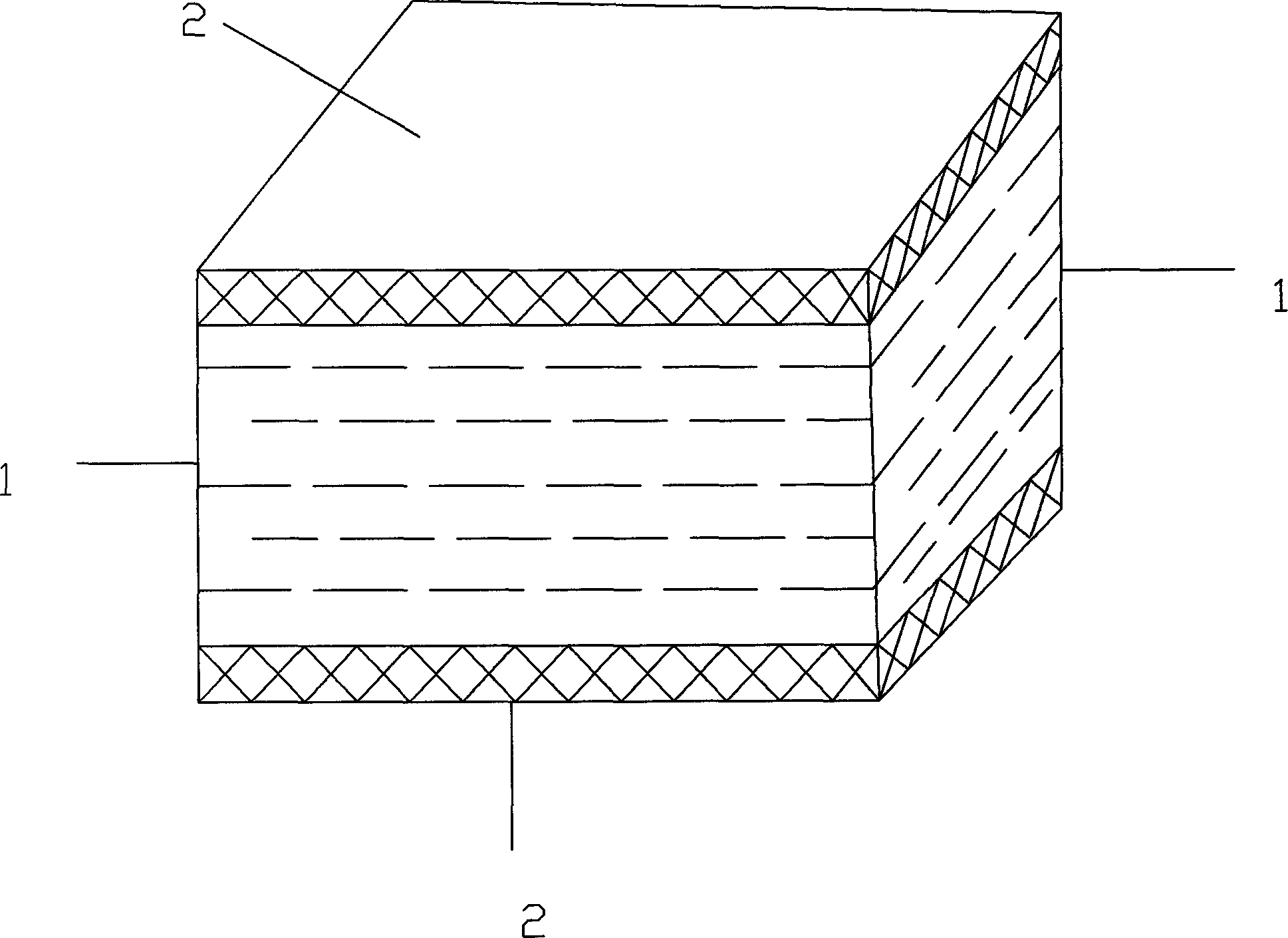

Image

Examples

Embodiment Construction

[0024] Before introducing the present invention, we should at first understand the fiber cotton production technology, and fiber cotton production mostly adopts glued cotton process or hot-melt cotton process, and these two processes are different.

[0025] Spray-bonded cotton is made of ordinary fibers using glue or surface layer netting to bond the surface structure. For example, the production process of spray-bonded cotton made of polyester (PET) fibers usually needs to go through a bale opener, a cotton opener, and an opening machine. After that, it is sent to the cotton feeder, and then combed into a thin layer by a carding machine, that is, the fibers are distributed in two dimensions, and then the polyester (PET) fiber layer in a two-dimensional distribution is folded with a forming machine It is made into the required thickness, sprayed with adhesive, and combined with layers of fibers, and dried.

[0026] The hot-melt cotton process uses the low-melting point composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com