Composite additive for flue gas desulfurization according to limestone method

A composite additive, limestone technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of unqualified desulfurization drainage chromaticity, reduced desulfurization efficiency, slow reaction process, etc., to ensure efficient and stable operation, The effect of improving desulfurization efficiency and improving oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

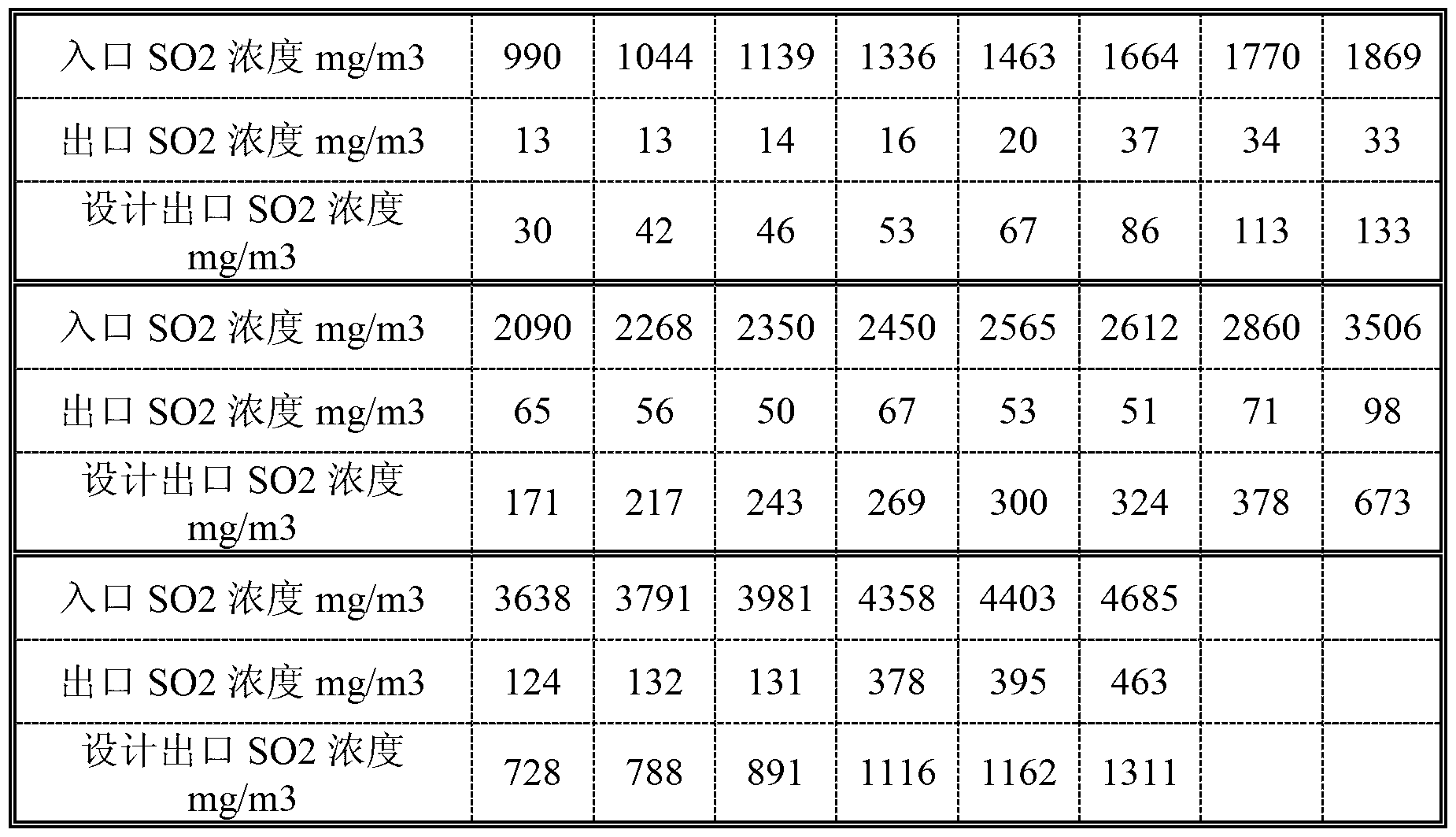

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment.

[0018] Embodiment Carry out the production of nylon acid extraction residue first. The specific steps are:

[0019] (1) Take 200kg of nylon acid, put it in a stirring tank, and add 800kg of nylon acid desalted water into the stirring tank;

[0020] (2) Start the stirrer, heat slowly, control the heating speed at 3-5°C / min, and keep the temperature constant for 1 hour after heating to 50°C;

[0021] (3) Pass cooling water into the mixing tank, slowly cool down, the cooling rate is 2-3°C / min, and keep the temperature for 2 hours after the temperature drops to 15°C.

[0022] (4) After constant temperature for 2 hours, vacuum filtration is used to remove the filtrate. The remaining crystals in the stirring tank are the residues of nylon acid extraction.

[0023] Then take 88kg of nylon acid extraction residue, 2kg of salicylic acid, 2kg of humic acid, 3kg of manganese chloride and 5k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com