A method of using waste animal and vegetable oil to produce aviation biofuel

A technology of animal and vegetable oils and biofuels, which is applied in the direction of biological raw materials, fat oil/fat refining, and preparation of liquid hydrocarbon mixtures, etc. It can solve the problems of large-scale, long-term operation, inability to fully meet quality requirements, and coking of the catalyst bed. or fouling, to avoid poisoning, increase operational flexibility, and slow down coking or fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

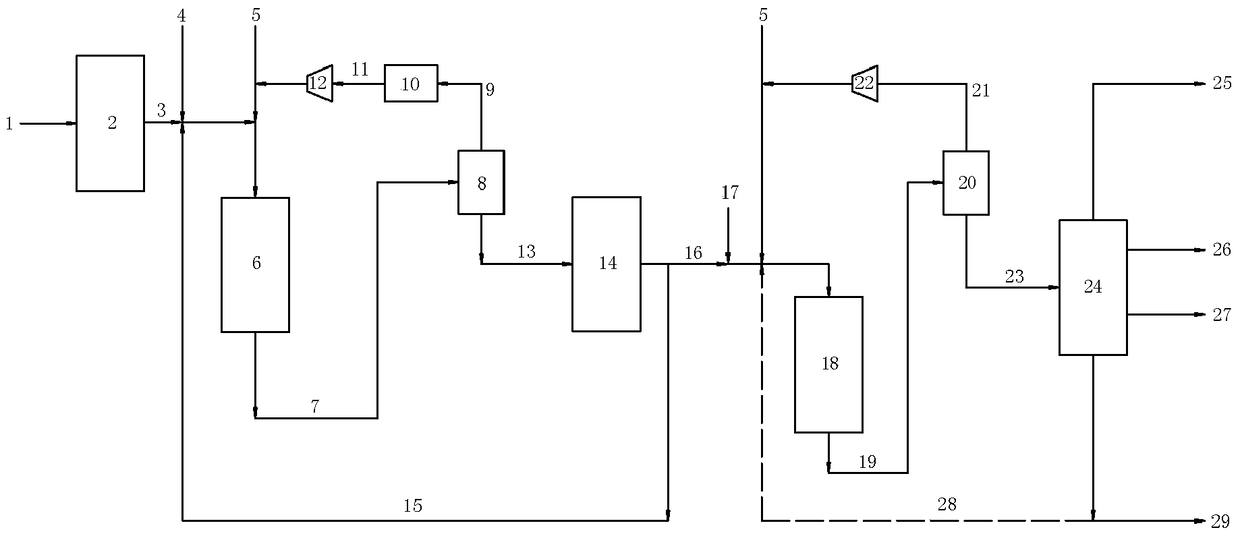

[0046] The raw material oil 1 directly enters the pretreatment unit 2, removes mechanical impurities, chlorine, metals, and water in the raw material through filtration-electric desalination and reduces the acid value, and the pretreated oil 3 is mixed with the vulcanizing agent 4 and the hydrorefined circulating oil 15, Then, under the injection of the mixed hydrogen flow of new hydrogen 5 and circulating hydrogen 11, it enters the hydroprocessing unit 6 to remove impurities such as oxygen, sulfur, nitrogen, chlorine and metals, and the hydroprocessing gas-liquid stream 7 enters the gas-liquid separator 8 , the high fraction gas phase 9 obtained by separation is removed carbon monoxide, carbon dioxide and light hydrocarbons by a pressure swing adsorption unit 10 to obtain a circulating hydrogen 11, which is boosted by a compressor 12 and then circulated to the inlet of the hydroprocessing unit to be mixed with new hydrogen 5. The separated liquid hydrocarbons 13 enter the dega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com