Manufacturing method of high-precision, high-reliability ntc thermistor chip

A technology of a thermistor chip and a manufacturing method, which is applied in the manufacturing field of high-precision and high-reliability NTC thermistor chips, can solve the problems of low temperature, influence on electrical conductivity and welding performance, silver layer oxidation, etc., so as to reduce sintering The effect of temperature and efficient sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

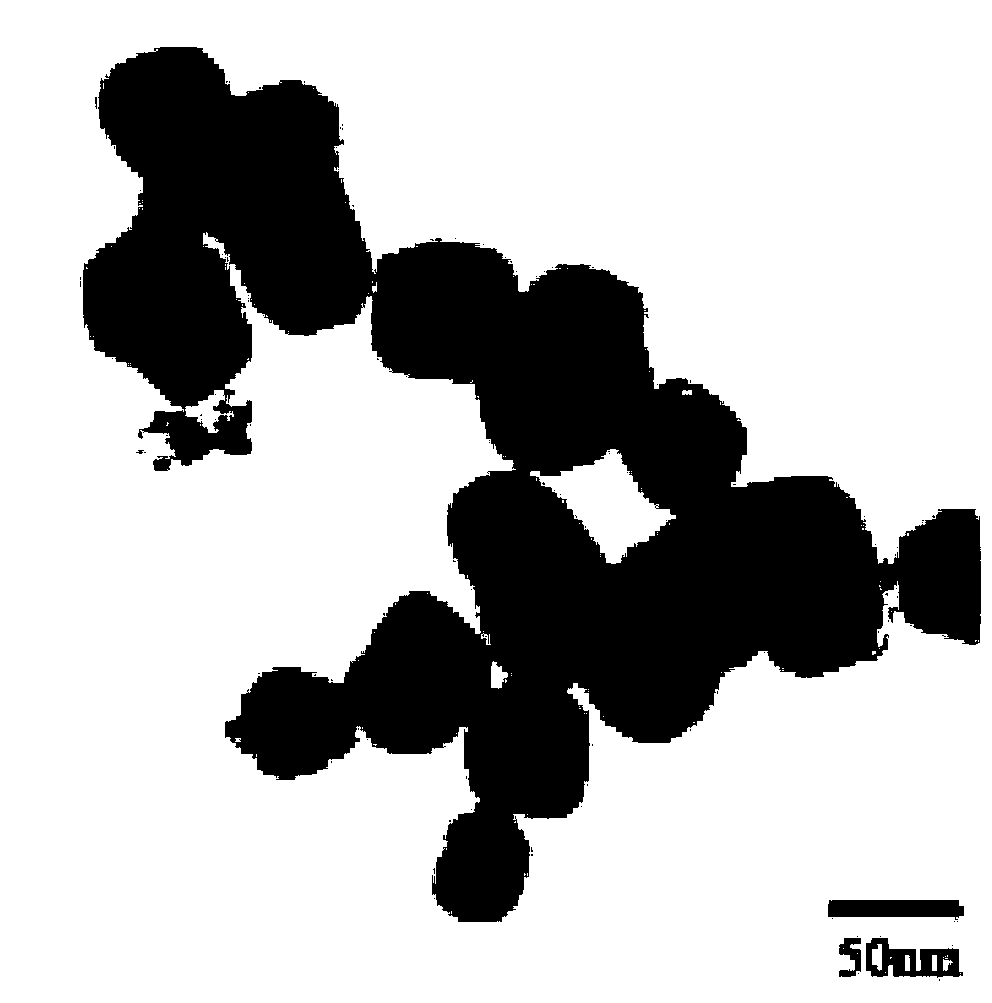

Embodiment 1

[0044]Use an analytical balance to accurately weigh 405.2g of manganese tetraoxide, 457.04g of nickel oxide, 599.30g of ferric oxide, and 39.42g of aluminum oxide. The above mixture is ball-milled for 20 hours, dried, crushed, and calcined at 950°C for 2 hours, and then again Ball mill for 20 hours to get traditional coarse powder (particle size of powder is 1-5μm). According to the same molar ratio of metal ions, nickel nitrate, manganese nitrate, iron nitrate and aluminum nitrate were formulated into a 0.7mol / L aqueous solution, adjusted to pH = 7 with ammonia water, ultrasonically spray-dried under stirring, and calcined at 450°C for 4 hours to obtain Nano powder. Weigh 375g of this nano-powder and add it to the coarse-grained powder, and add deionized water to make a slurry while stirring. 25wt%. Filter the mud in a filter press molding mold, pressurize at 10Mpa, hold the pressure for 2 minutes, make a cylinder with a diameter of 52mm and a height of 16mm, bake at 100°C ...

Embodiment 2

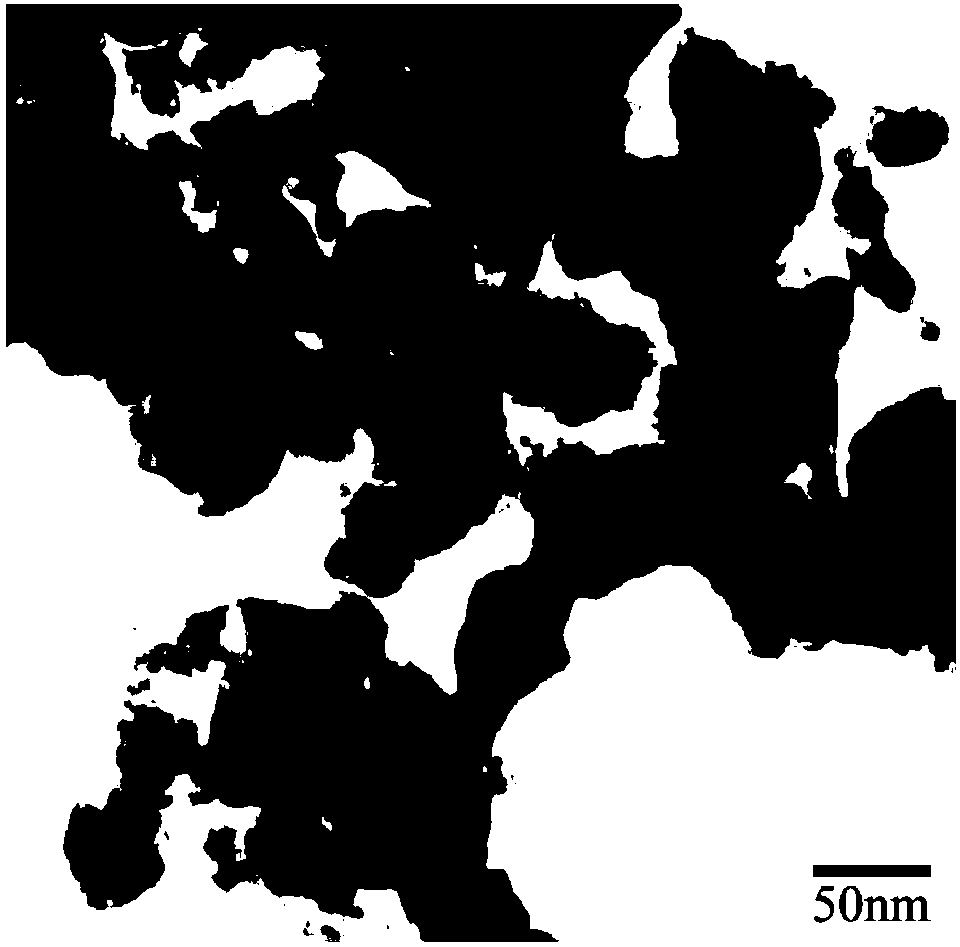

[0052] Use an analytical balance to accurately weigh 385.1g of trimanganese tetraoxide, 146.48g of nickel oxide, 499.30g of ferric oxide, and 500.31g of cobalt oxide. The above mixture is ball milled for 20 hours, dried, crushed, and calcined at 850°C for 2 hours, and then again Ball mill for 20 hours to get traditional coarse powder (particle size of powder is 1-5μm). According to the same molar ratio of metal ions, nickel nitrate, manganese nitrate, iron nitrate and cobalt nitrate were formulated into a 0.7 mol / L aqueous solution, adjusted to pH = 7 with ammonia water, ultrasonically spray-dried under stirring, and calcined at 500 ° C for 4 hours to obtain Nano powder. Weigh 689g of this nano-powder and add it to the coarse-grained powder, and add deionized water while stirring. The amount of water added accounts for 25wt% of the mixed powder (ie, the above-mentioned nano-powder + coarse-grained powder). Filter the mud in a filter press forming mold with a pressurization pr...

Embodiment 3

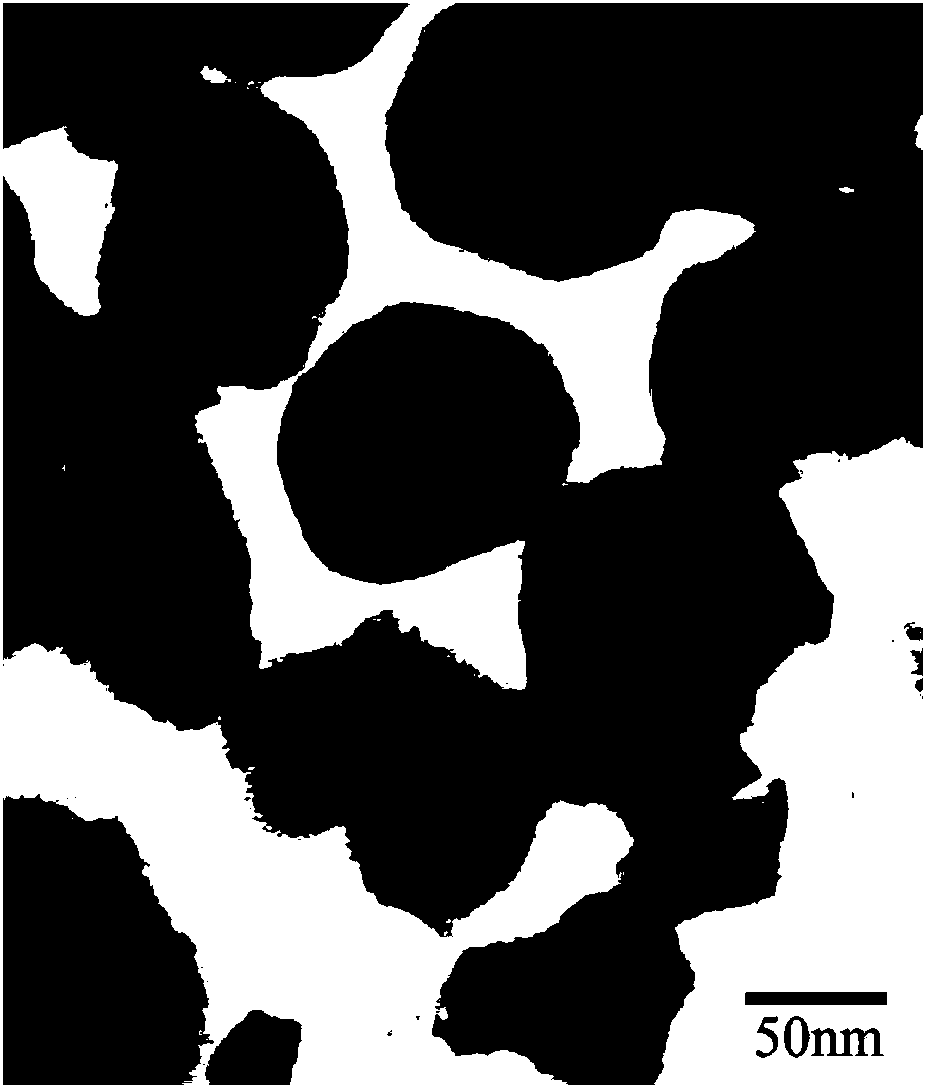

[0060] Use an analytical balance to accurately weigh 420.2g of manganese tetraoxide, 487.04g of cobalt oxide, 499.30g of ferric oxide, and 40.40g of aluminum oxide. The above mixture is ball milled for 20 hours, dried, crushed, and calcined at 1000°C for 2 hours, and then again After ball milling for 20 hours, traditional coarse powder (particle size of powder is 1-5 μm) is obtained. According to the same molar ratio of metal ions, cobalt nitrate, manganese nitrate, iron nitrate and aluminum nitrate were formulated into a 0.7 mol / L aqueous solution, adjusted to pH = 7 with ammonia water, ultrasonically spray-dried under stirring, and calcined at 500 ° C for 4 hours to obtain Nanocomposite powder. Weigh 506.2g of this nano powder and add it to the coarse powder, add deionized water while stirring, the amount of water added accounts for 25wt% of the mixed powder (namely the above nano powder + coarse powder) . Filter the mud in a filter press molding mold, pressurize at 10Mpa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com