Preparation method and application of alkylated functional graphene

A functional graphene, alkylation technology, applied in the treatment of dyed low molecular organic compounds, fibrous fillers, etc., can solve the problem that the excellent properties of graphene cannot be maximized, have not been well solved, and the dispersion of graphene is poor. and other problems, to achieve the effects of excellent comprehensive performance, improved machinability, and improved interface bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

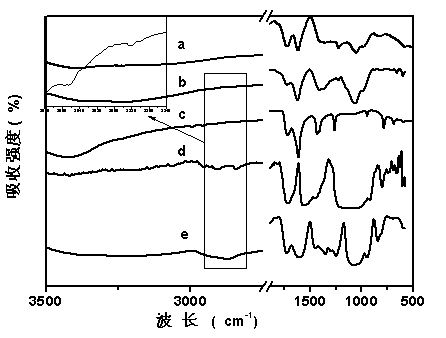

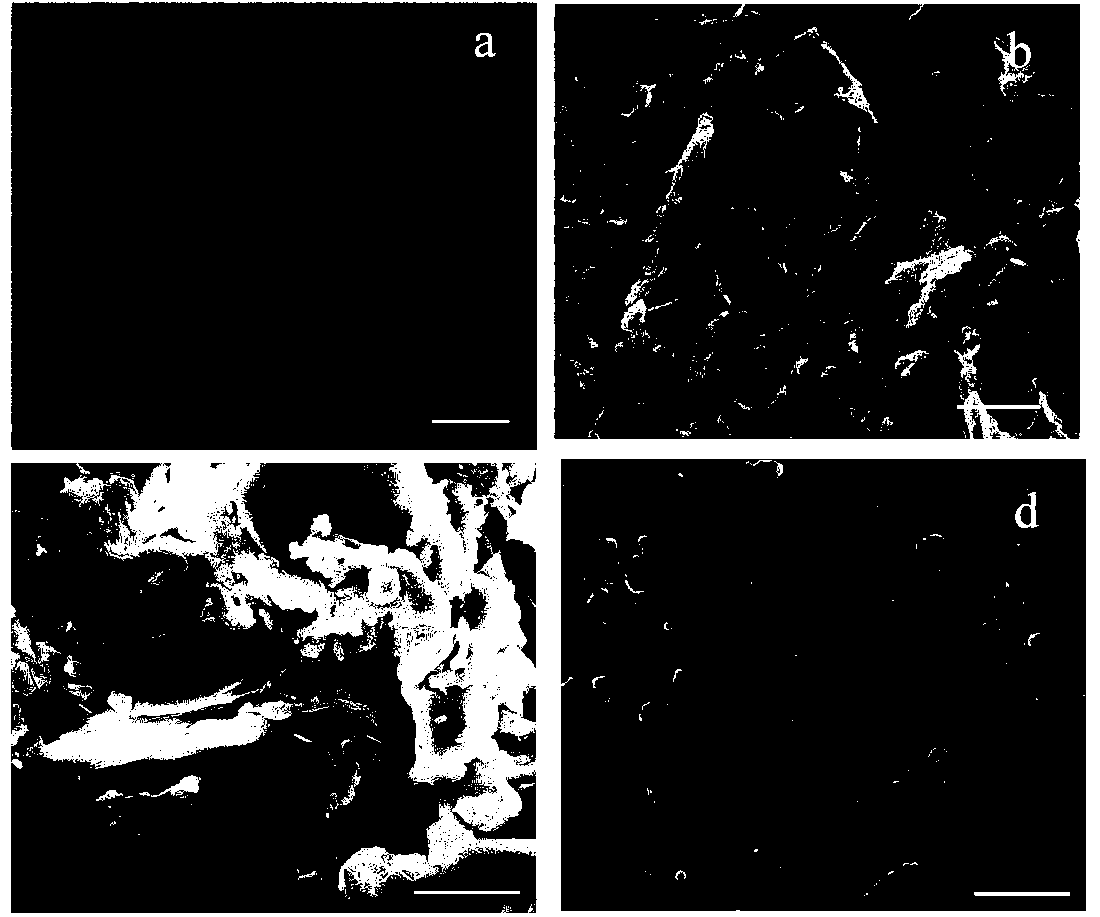

[0029] Example 1: Disperse 0.5 g of monolayer graphene oxide prepared by the Hummers method in 50 mL of acetone-distilled water (the volume ratio of acetone to water is 10:1), ultrasonicate for 3 hours to obtain a functional graphene dispersion, and then The dispersion liquid is placed in ethanol-water solution, washed repeatedly and centrifuged at a speed of 10000 rpm, and finally the precipitate is freeze-dried to prepare the alkylated functional graphene. Prepare an aqueous solution of 50% nylon 66 salt, add alkylated functional graphene to it at a weight ratio of 10:1, ultrasonically 1h, and obtain 10% functional graphene / PA66 masterbatch by in-situ polymerization, then, the above prepared The functional graphene / PA66 masterbatch and PA66 resin are mixed uniformly through a high-speed pulverizer at a mass ratio of 1:5, and then melted, blended and extruded to obtain a PA66-based nanocomposite material with a weight content of 2% functional graphene.

Embodiment 2

[0030]Example 2: Disperse 0.8 g of single-layer graphene oxide prepared by the Hummers method in 100 mL of 2-pentanone-distilled water (the volume ratio of 2-pentanone to water is 5:1), and sonicate for 1 hour to obtain functional graphene The dispersion liquid is then placed in an ethanol-water solution, washed repeatedly and centrifuged at a speed of 10,000 rpm, and finally the precipitate is freeze-dried to prepare the alkylated functional graphene. Prepare an aqueous solution of 50% nylon 66 salt, add alkylated functional graphene into it at a weight ratio of 10:1, ultrasonically 1h, and obtain 10% functional graphene / PA66 masterbatch by in-situ polymerization, then, the above prepared The functional graphene / PA66 masterbatch and PA66 resin are mixed uniformly through a high-speed pulverizer at a mass ratio of 1:10, and then melted, blended and extruded to obtain a PA66-based nanocomposite material with a weight content of 1% functional graphene.

Embodiment 3

[0031] Example 3: Disperse 0.5 g of single-layer graphene oxide prepared by the Hummers method in 100 mL of 2-heptanone, and ultrasonicate for 5 hours to obtain a functional graphene dispersion, and then place the dispersion in ethanol-water solution, repeating it several times Wash and centrifuge at a speed of 10,000 rpm, and finally freeze-dry the precipitate to prepare alkylated functional graphene. Prepare an aqueous solution of 50% nylon 66 salt, add alkylated functional graphene to it at a weight ratio of 20:1, ultrasonically 1h, and obtain 5% functional graphene / PA66 masterbatch by in-situ polymerization, and then prepare the above-mentioned The functional graphene / PA66 masterbatch and PA66 resin are mixed uniformly through a high-speed pulverizer at a mass ratio of 1:5, and then melted, blended and extruded to obtain a PA66-based nanocomposite material with a weight content of 1% functional graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com