Micropore luminous composite material and preparation method thereof

A composite material and microporous technology, which is applied in the field of microporous luminescent composite materials and their preparation, can solve the problems of no visual detection means, low product purity, expensive synthetic raw materials, etc., and achieve good stability of the main structure and high product purity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 0.216g lanthanum nitrate, 0.118g succinic acid, and 0.062g isonicotinic acid in 10 mL H 2 O middle. After stirring evenly, add a few drops of ammonia water until the pH of the solution is 4.2, showing a weakly acidic solution. The above solution was sealed in a stainless steel polytetrafluoroethylene-lined reaction kettle and heated at 160° C. for three days. Cool to room temperature at a rate of 5°C per hour. The product is a colorless needle-like crystal, which can be used after washing several times with water. Yield 41%.

Embodiment 2

[0026] Dissolve lanthanum nitrate, succinic acid, and isonicotinic acid in a molar ratio of 1:2:1 in 10-20 mL H 2 O, stir evenly, add ammonia water until the pH value of the solution is 4.2;

[0027] (2) The above solution was sealed in a stainless steel polytetrafluoroethylene-lined reaction kettle, heated at 150°C for 4 days; cooled to room temperature at a rate of 4°C / h, and the product was a colorless needle-like crystal.

Embodiment 3

[0029] Dissolve lanthanum nitrate, succinic acid, and isonicotinic acid in a molar ratio of 1:2:1 in 10-20 mL H 2 O, stir evenly, add ammonia water until the pH value of the solution is 4.2;

[0030] (2) The above solution was sealed in a stainless steel polytetrafluoroethylene-lined reaction kettle, heated at 170°C for 2 days; cooled to room temperature at a rate of 6°C / h, and the product was a colorless needle-like crystal.

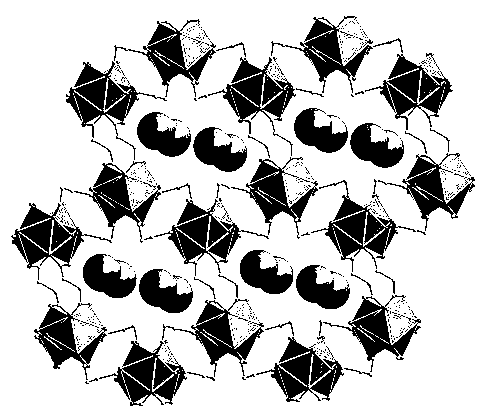

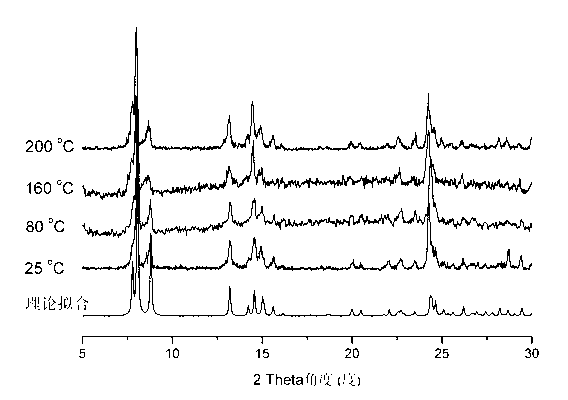

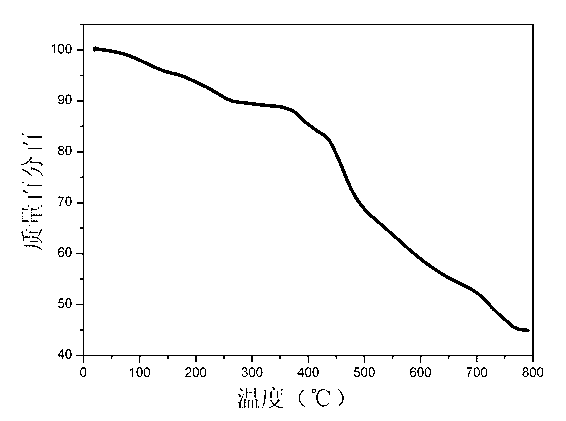

[0031] Product characterization: Select a single crystal with good crystal phase, suitable size and no obvious defects in the product, and use X-ray single crystal diffractometer to collect diffraction data for structural analysis. The data of the single crystal structure shows that it is a metal-organic composite material, and the structure of the material contains nano-sized pores, which are occupied by free water molecules. The product was subjected to X-ray powder diffraction to characterize the crystal phase and purity of batches of macroscopic pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com