Method for preparing gas by using biomass and coal

A biomass and gas technology, applied in the manufacture of combustible gas, granular/powdered fuel gasification, petroleum industry, etc., can solve the problem of limited tar treatment, reduce energy consumption, reduce emissions, reduce emissions and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

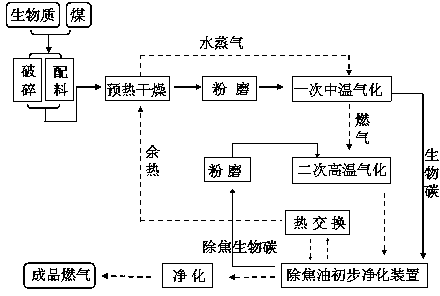

Image

Examples

Embodiment 1

[0029] Embodiment 1: the method for co-production of gas by biomass and coal, the specific operations are as follows:

[0030] (1) Using straw and cow dung as the main biomass raw materials, crush the straw so that the particle size is less than 2 cm, preheat and dry to a moisture content of 3%, and the mass ratio of straw and cow dung is 1:1. The waste heat obtained in the process preheats and dries the straw and cow dung (this step requires heat from an external source when starting up for the first time), and the water vapor generated during the drying process is transported to a medium-temperature gasification device;

[0031] (2) Send the dried material in step (1) into a grinding equipment, and the particle size of the material after grinding is less than 1mm to obtain powdery biomass;

[0032] (3) The powdery biomass and pulverized coal obtained in step (2) are sent to a medium-temperature gasification device, and the water vapor generated in step (1) is gasified in a m...

Embodiment 2

[0038] Embodiment 2: the method for co-production of gas by biomass and coal, the specific operations are as follows:

[0039] (1) Using straw and bean dregs as the main biomass raw materials, crush the straw so that the particle size is less than 2 cm, preheat and dry to a moisture content of 2%, and the mass ratio of straw to cow dung is 2:1. The obtained waste heat preheats and dries the straw and bean dregs (this step requires heat from an external source when starting up for the first time), and the water vapor generated during the drying process is sent to a medium-temperature gasification device;

[0040] (2) Sending the dried material in step (1) into a grinding equipment, and the particle size of the material after grinding is less than 1 mm to obtain powdery biomass.

[0041] (3) The powdered biomass and coal powder obtained in step (2) are sent to a medium-temperature gasification device, and the water vapor generated in step (1) is gasified in a medium-temperature...

Embodiment 3

[0047] Embodiment 3: the method for the co-production of gas by biomass and coal, the specific operations are as follows:

[0048] (1) Using sawdust and branches and leaves as the main biomass raw materials, the wood chips and branches and leaves are crushed to make the particle size less than 2 cm, preheated and dried to a moisture content of 3%, and the mass ratio of wood chips and branches and leaves is 1:2. The waste heat obtained in the subsequent process preheats and dries the wood chips and branches and leaves (this step requires heat from an external source when starting up for the first time), and the water vapor generated during the drying process is transported to the primary medium-temperature gasification device;

[0049] (2) Sending the dried material in step (1) into a grinding equipment, the particle size of the material after grinding is less than 1 mm, and powdery biomass is obtained;

[0050] (3) The powdery biomass and pulverized coal obtained in step (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com